More progress as been done, but not without difficulties.

When doing research and finding articles , pictures and videos, it's not always black and white. Picture of the final results are not always explanatory, articles are sometimes, (or almost always) written in terms of specialist and not common everyday people and videos don't always show exactly what as to be done. This is why questions need to be asked. But again, lots of answers are often vague or off subject.

I wanted a system which for now could run my trains without having to undo what I had done. At a later stage I would like to have my layout linked to a computer, so toggle switch was out since a toggle switch can't toggle if action was done on a computer. A push button would solve this (seen on a video), but how?

I read that NCE had a push button board that could accept 8 push button which then linked to a switch8 could activate 8 tortoises. GREAT, but how does all this work and how to wire all this together? More reading and I then find out I need 2 push button per tortoises, the reason why the button board has 16 inputs. PROBLEM...... I don't want two buttons, I want one, now what?

More videos, pictures and reading, now I want LED's to be activated on a control board, but how do I do that? There are single LED's, Bi-color 2pin and 3 pin, etc etc. I need help!!!

After posting for help here, my hangout group, on Facebook and on the NCE Yahoo group, I finally got all the answers needed to continue. Like I said earlier, I get all kinds of answers, like I'm talking about push buttons and I get an answer on toggle switches, but I do appreciate the help.

I've been working on my hardware board as shown here:

View attachment 59660

The square hardware is the button board, I need two, therefore 16 push button. I did get the answer for installing one push button instead of two. All I need to do is reprogrammed the board, which to me was WHAT????? It ended up being very simple. "Setting CV548 = 1 will cause each push-button connected via the ‘Button Board’ to ‘toggle’ the switch machine output, i.e. each press of one button will alternate the switch’s position. Thus only 8 push-buttons are needed; each is connected to an ‘N’ terminal, so less wires in the control panel. Setting CV548 = 0 disables it. (Factory default = 0)."

The two identical rectangular hardware are the Switch8 which will activate the tortoises, that one was simple.

The rectangular piece at top is the circuit breaker

You can see my push button that is temporarily installed, I tested the system and ran a train with 2 LED's for the future panel and everything WORKED as I wanted. For me this is a great step forward since when it comes to electronics or electricity, I'm illiterate.

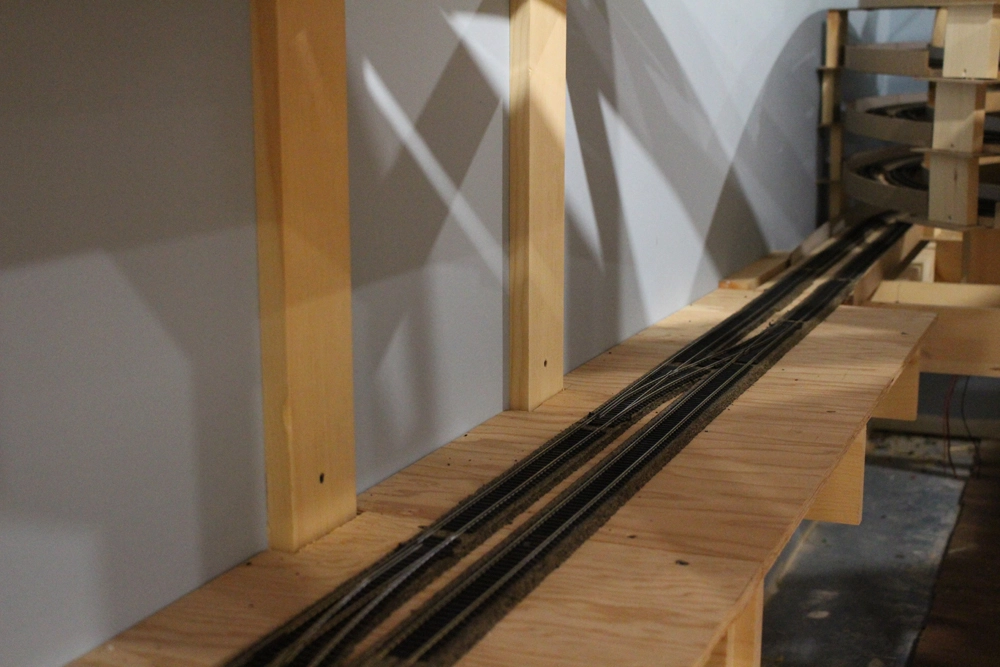

[FONT=&]Half of my staging area is completed, that includes, soldering, wiring, tortoises. Hope to have the rest finished by year end, except for the control panel as I'm waiting for more LED's.

View attachment 59661

Not much to show, but lots is getting done.

Thanks to those that took the time to help me

Later

[/FONT]