CMMR

Member

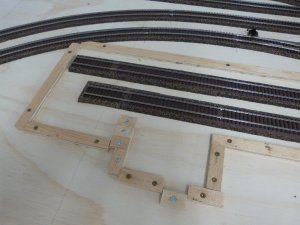

Besides restoring the Brawa crane over the winter I have also been putting down track. Before I can finish the track work I wanted to assemble the engine house and test fit it. I wanted something that kind of resembles the actual CEMR shops, but I don't have room for 3 stalls, so I picked up the Pikestuff 541-0008 2-stall kit as well as the 541-0011 office/showroom.

Here are a couple of shots of the actual CEMR shops.

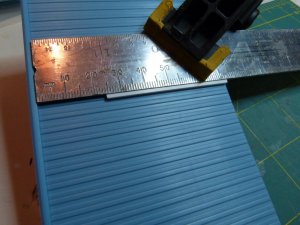

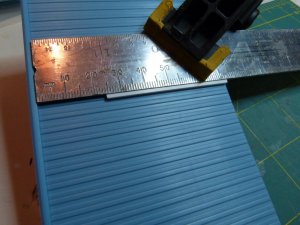

I laid out the pieces of the 2 kits and figured out what kind of window and door configurations I wanted. Once I was happy with them I cut out all of the openings and test fit the windows and doors. Next I started to assemble the walls. Here is my fancy corner jig made out of 2 magnetic welding clamps and a steel rule.

I glued a couple of strips of styrene to the main shop wall to brace the office walls.

Here are a couple of shots of the actual CEMR shops.

I laid out the pieces of the 2 kits and figured out what kind of window and door configurations I wanted. Once I was happy with them I cut out all of the openings and test fit the windows and doors. Next I started to assemble the walls. Here is my fancy corner jig made out of 2 magnetic welding clamps and a steel rule.

I glued a couple of strips of styrene to the main shop wall to brace the office walls.