You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

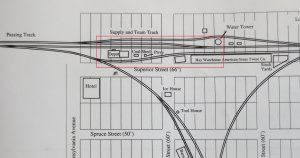

New Layout for LASM

- Thread starter logandsawman

- Start date

logandsawman

Well-Known Member

logandsawman

Well-Known Member

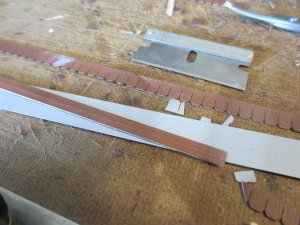

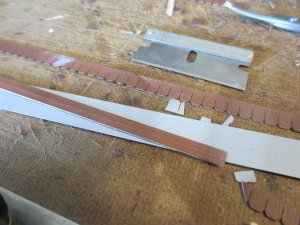

Well, I got going on the shingles yesterday, started out with painting them:

I used a flat brown spray (tamiya) and added some gray dry brushing with a touch of india ink added to the palette:

Here I drew on some lines for guides, also painted the top edges black with a marker so the underlying material would not show through the notch:

Here in putting on the second row it looks like a scale 1' board will make the appropriate spacing:

I am using the toothpick to apply the white all purpose elmers glue, this is how much I am putting on:

I wonder if I should space the rows closer? These come off pretty easily with an exacto knife so still not too late to make an adjustment.....

I used a flat brown spray (tamiya) and added some gray dry brushing with a touch of india ink added to the palette:

Here I drew on some lines for guides, also painted the top edges black with a marker so the underlying material would not show through the notch:

Here in putting on the second row it looks like a scale 1' board will make the appropriate spacing:

I am using the toothpick to apply the white all purpose elmers glue, this is how much I am putting on:

I wonder if I should space the rows closer? These come off pretty easily with an exacto knife so still not too late to make an adjustment.....

Bruette

Well-Known Member

Hey David,

When I first looked at this picture I thought it was an asphalt paper roof until I clicked on the picture and looking closely I could see it was blue ink. Maybe you can file that idea away for another project.

Great work and thanks for sharing!

PS any plans for new YouTube videos?

When I first looked at this picture I thought it was an asphalt paper roof until I clicked on the picture and looking closely I could see it was blue ink. Maybe you can file that idea away for another project.

Great work and thanks for sharing!

PS any plans for new YouTube videos?

santafewillie

Same Ol' Buzzard

Dave - As long as the upper row just barely overlaps the spaces between the shingles in the row below it, your spacing should be good. I worked for a roofing company 47 years ago, and nothing has changed.

Willie

Willie

logandsawman

Well-Known Member

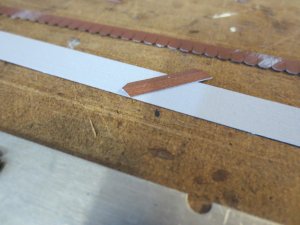

Hi Willie, that makes sense. I was using the same reasoning. When I looked at the prototype photo, it looked like they had their shingles closer together, so I tightened them up from a scale 12" to scale 8" exposed. Not a huge difference but my wife thought the appearance was better.

Here is taking off the old row, it went easily, helping me understand how much glue it was going to take. Some came off a little too easy so I have to be sure and get enough but not have it gooping out all over the place. Luckily, a little white glue coming out does not show at all:

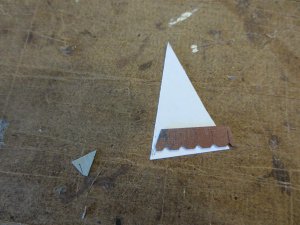

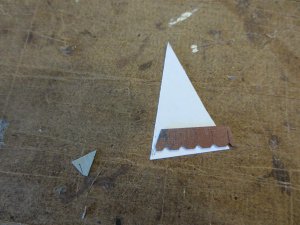

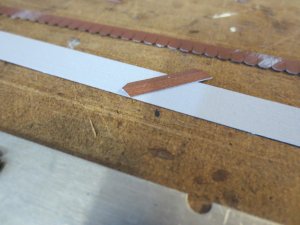

I made this cut-out to help me get the strip sizes for the turret; I am only putting on a few strips at a time so they can dry and not risk being moved around as the glue takes a while to set up:

Here I have a few rows done, I am trying to use shingles from different places on the sheet so the whole thing ties together well. I am also just putting on a row or two in an area at a time so they can set up and I do not risk moving them in the handling process:

\

\

It looks like I need to straighten that last row a little. I have a scale 8 x 8" that I have been using to get them right, but if I am not careful it is easy to slip them out of place.

Here is taking off the old row, it went easily, helping me understand how much glue it was going to take. Some came off a little too easy so I have to be sure and get enough but not have it gooping out all over the place. Luckily, a little white glue coming out does not show at all:

I made this cut-out to help me get the strip sizes for the turret; I am only putting on a few strips at a time so they can dry and not risk being moved around as the glue takes a while to set up:

Here I have a few rows done, I am trying to use shingles from different places on the sheet so the whole thing ties together well. I am also just putting on a row or two in an area at a time so they can set up and I do not risk moving them in the handling process:

\

\It looks like I need to straighten that last row a little. I have a scale 8 x 8" that I have been using to get them right, but if I am not careful it is easy to slip them out of place.

logandsawman

Well-Known Member

Hi Louis, just caught your post, I do plan on making a youtube video out of this construction project, I have the whole process documented and it will be something of a slide show so if anyone wants to copy the build they can pause on the step and study it more carefully.

The way it looks in a week or two it should be complete and I can get working on the video.

The way it looks in a week or two it should be complete and I can get working on the video.

logandsawman

Well-Known Member

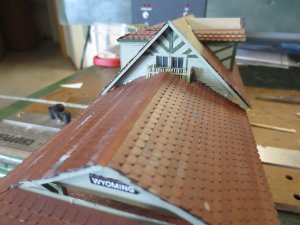

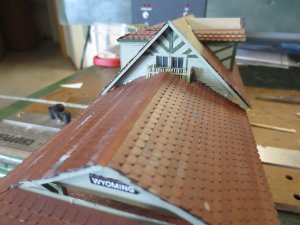

Several more rows are now applied to the depot, as shown:

Realized if I try to put too many on at once there is a chance some will be moved, as the glue does not adhere immediately.

There is a spot on the other side where a row slid down a little and I didn't catch it until the next day. It bothers me, but not enough to take up another row with the razor blade.

Realized if I try to put too many on at once there is a chance some will be moved, as the glue does not adhere immediately.

There is a spot on the other side where a row slid down a little and I didn't catch it until the next day. It bothers me, but not enough to take up another row with the razor blade.

logandsawman

Well-Known Member

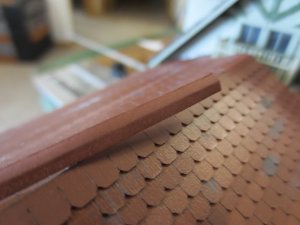

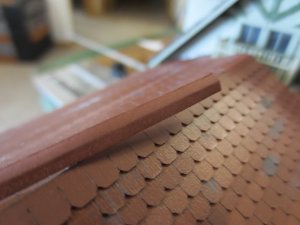

Here are a few pics of the ridge piece I am putting on, and how it looks attached over the porch section of the depot; I am unable to bend the shingles because they are too thick. I think they made them that way so they would not curl.

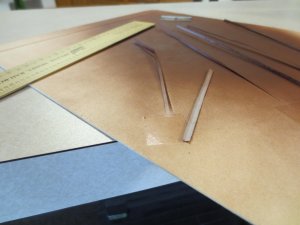

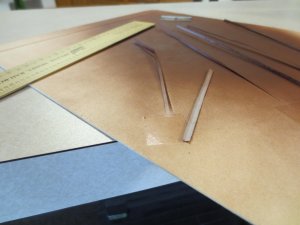

To make the ridge piece, I used receipt paper because it is thin and strong. First I folded the paper, then cut it into narrow strips with the exacto knive and steel ruler, then taped them to this cardboard and spray painted with the same model paint I used on the shingles:

This is how they looked after taking off the cardboard backing piece:

Here I am checking out the fit, I didn't measure here but eyeballed the dimensions, I made several so if one size didn't look right I could use a different one:

Here I have it attached to the building; I used the same all purpose Elmers glue that I am using on the shingles, applied full strength with a toothpick, trying to get enough on for good adherence but not so much that it oozes out the edges:

To make the ridge piece, I used receipt paper because it is thin and strong. First I folded the paper, then cut it into narrow strips with the exacto knive and steel ruler, then taped them to this cardboard and spray painted with the same model paint I used on the shingles:

This is how they looked after taking off the cardboard backing piece:

Here I am checking out the fit, I didn't measure here but eyeballed the dimensions, I made several so if one size didn't look right I could use a different one:

Here I have it attached to the building; I used the same all purpose Elmers glue that I am using on the shingles, applied full strength with a toothpick, trying to get enough on for good adherence but not so much that it oozes out the edges:

logandsawman

Well-Known Member

Thanks, Chet; have made a little progress, got most of the shingles on; went to cutting some of the perimeter strips from the shingle pages for the corner flashing;

forgot to remark I used a black permanent marker to do the exposed edges, as the shingle paper has kind of a white color to it which contrasts the painted shingle color:

I am cutting strips from the actual shingle paper and score the back side with a knife, then bend along the score to get the bend made

Many of the shingles and corner pieces are on here,

STILL working on the turret, I made it so it can come off and on for ease of working

forgot to remark I used a black permanent marker to do the exposed edges, as the shingle paper has kind of a white color to it which contrasts the painted shingle color:

I am cutting strips from the actual shingle paper and score the back side with a knife, then bend along the score to get the bend made

Many of the shingles and corner pieces are on here,

STILL working on the turret, I made it so it can come off and on for ease of working

Awesome, DAVE!

That's going to be a focal point.

Great shingle work!

That's going to be a focal point.

Great shingle work!

logandsawman

Well-Known Member

Thanks, Sherrel, I spent a good deal of time on the turret yesterday and have some pics of the process for finishing it off,

Here you can see I am having a lot of difficulty getting the shingles to meet up nice, have been planning to cover the corner gap with something. Fortunately, the feature is designed to come in and out easily so I can work on it without disturbing the rest of the depot:

I filled in the gap with a bead of JB weld then after it set glued on strips of "flashing" which was made from the strips of receipt paper (which is thin but strong) painted the color of the shingles:

I mixed the jb weld with less hardener for this application so it would be more fluid and it could be laid into place without the batch hardening right away. This is JB quick which normally sets in 4 hours, but gets hard in a few minutes

Here the turret is in place and I am just about done:

Here you can see I am having a lot of difficulty getting the shingles to meet up nice, have been planning to cover the corner gap with something. Fortunately, the feature is designed to come in and out easily so I can work on it without disturbing the rest of the depot:

I filled in the gap with a bead of JB weld then after it set glued on strips of "flashing" which was made from the strips of receipt paper (which is thin but strong) painted the color of the shingles:

I mixed the jb weld with less hardener for this application so it would be more fluid and it could be laid into place without the batch hardening right away. This is JB quick which normally sets in 4 hours, but gets hard in a few minutes

Here the turret is in place and I am just about done:

santafewillie

Same Ol' Buzzard

Dave -

I worked as a roofer many many years ago, and even the pros had trouble getting them to meet up, even on less complex roofs.

Meanwhile, great job.

Willie

Here you can see I am having a lot of difficulty getting the shingles to meet up nice, have been planning to cover the corner gap with something.

I worked as a roofer many many years ago, and even the pros had trouble getting them to meet up, even on less complex roofs.

Meanwhile, great job.

Willie

logandsawman

Well-Known Member

Great work Dave, really fine work! The tile-work in combination with the architectural design got an impressive end result!

You inspired me to seriously look into a similar(-ish) structure in the subdivision that i model, the Arcadia depot (ATSF, 2nd district, LA division).

Thanks for posting!

You inspired me to seriously look into a similar(-ish) structure in the subdivision that i model, the Arcadia depot (ATSF, 2nd district, LA division).

Thanks for posting!

logandsawman

Well-Known Member

Thanks, Yannis and Johnny!