Finding a way to fit a motor inside the boiler of a small steam locomotive has been a problem for as long as there have been electric model trains. I have seen four solutions - make the model bigger, make the motor smaller, put the motor in the tender and run a drive shaft to the locomotive, or make the tender itself a pusher and let the engine roll freely.

The first option is out if you care about scale fidelity. The second is reasonable (and of course quite common) to a point, but it gets expensive and reduces the weight available for traction in extreme cases. That leaves the last two, both of which put the motor in the tender. That's the topic for the moment, and I'm just thinking out loud, and perhaps outside the box a little.

Option 1 - Motor in the tender, powered locomotive

There seem to be two major issues with this design, even though it is fairly common. One is that the drive shaft is visible, the other is the torque reaction which can, in extreme circumstances, lift the tender off the track.

It seems to be that the drive shaft could be dealt with in a couple ways. The first would be to try to get it as low as possible - ideally underneath the deck plate. That should make it all but invisible, or at least unobtrusive. If you're designing the drive, it might be possible to mount the work below the axle instead of above it, and possibly angle the drive shaft if necessary. The other thing to do would be to make it as small as possible - I've seen some made out of brass or steel wire. Of course, a thin wire cannot handle a lot of torque, so there is a limit to how small you can go, but it can definitely be smaller than the typical chunky plastic drive shaft seen in a number of models.

The bigger issue is the torque reaction, but this has me puzzled. It's simple enough, of course - the motor turns the body of the tender instead of the drive wheels. My question is why we don't see the same thing with diesel models, especially light ones. After all, the motor is not rigidly mounted to the wheels, and the body can rock, so why don't we see the same torque reaction there? I suspect there are two reasons, both of which can help solve the problem in steam engines. One is that there is a much wider and more solid bearing surface on a typical diesel truck, compared to a typical tender truck. In other words, the frame and trucks are more tightly and securely connected and less free to rock. The other is that the typical diesel frame is fairly heavy, while the typical tender frame is quite light. The heavier the frame is, the easier it is for the motor to turn it instead of the gears.

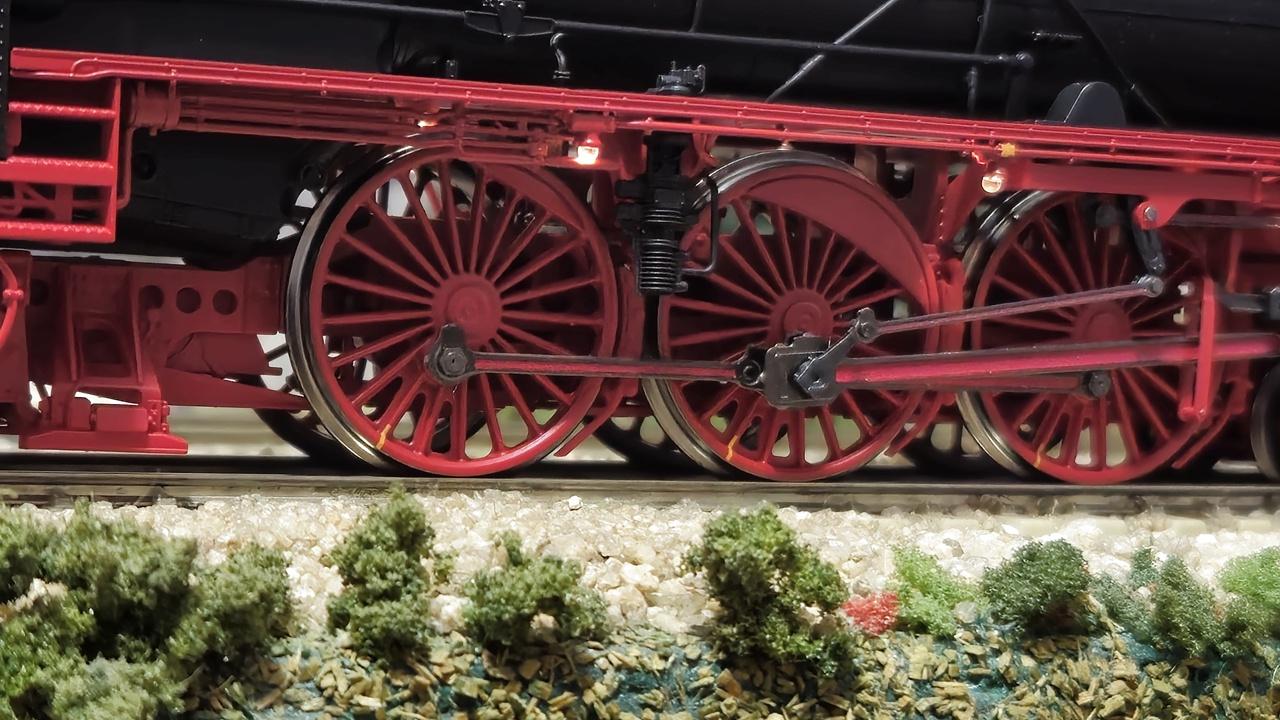

Another issue that may come into play is that some steam locomotives do not run as freely as diesels. Rods bind if not properly installed. All in all, it seems as though our steam models were engineered a century ago and have not changed ever since - an axle running in a slot in a solid chunk of metal is far from the ideal design. Diesels have the advantage of better design (most have bearings, many steamers do not) and more careful manufacture.

So the solution to the problem of a tender drive seems to be to make sure the chassis runs perfectly, don't allow the tender body to rock on the trucks, weight the tender as much as possible, and keep the drive shaft as low and as small as possible. I think that if all that were done, a tender drive could be a perfectly viable design and no worse than other designs.

Option 2 - Powered tender, free rolling engine

With a couple exceptions this is a rare design in the US, and seems to be looked down upon. There seems to be a lot to recommend it, and few real drawbacks, so I'm not sure why it is so rare.

The advantages are a much simpler diesel-style mechanism which can very easily be hidden, and complete freedom in designing the frame and boiler, leaving the space between open as on the prototype. The disadvantage is that a chassis which does not roll freely could bind and slide in front of the tender.

Some people dislike the design simply because they feel that the model should be powered like the prototype, with the drivers doing the pulling. I doubt those same people have a problem with a model E8 with all six axles powered, however. The objective is to build a functional model which runs reliably, pulls a prototypical load, and disguises as much as possible the fact that it is not a steam powered locomotive. An electric motor driving the tender wheels seems no less prototypical than an electric motor driving spoked wheels underneath a lead weight, in my opinion.

The other complaint I have heard is that some people like to see the drivers slipping pulling a heavy grade or starting a train. While prototypical, I feel that slipping the drivers should be avoided on a model. It wears out the drivers and doesn't really achieve anything useful. It reminds me of those videos showing guys burning the tires off their cars and motorcycles - testosterone fueled silliness.

In other words, I tend to dismiss the esthetic and conceptual complaints entirely. As for the chassis binding - any steam locomotive, no matter how it is powered, should be able to roll perfectly without the motor connected to the drivers. If it doesn't, that's a problem with the model, not the design. While a pusher design is less forgiving of poor engineering, to me that is not a reason to dismiss the design. It's a reason to improve the model.

So what?

Like I said, I'm just thinking out loud. But I'd like to see people consider these designs for difficult cases, and perhaps not feel so ashamed or apologetic about doing so. I would also like to see people pushing the limits, seeing just how well they can use the designs to better achieve a smooth running and prototypical model.

Ken Rickman