Renegade1c

Member

Rick,

Mounting these things is one thing, wiring them is another. I have looked at a number of pictures of their wiring (all of which seem to include multiple machines, extra bits of electronics, lights and other stuff that just confuses me. I have not been able to locate a single diagram that shows the simplest most basic wiring of these things.

I am assuming that the tortoise gets its power from the track power/main Bus with one wire attached to it at either end terminal. If that is the case, then all I should need to do is run two more wires, from the tortoise, to my toggle switch so it will work. Is that about it?

You would be much better off wiring them to an accessory bus than to track power. If you short (I'm assuming DCC here) you lose the ability to reset turnout with out physically moving the train and clearing the short first.

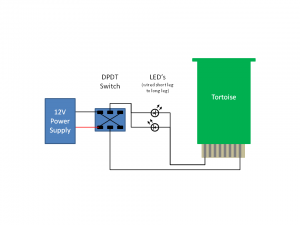

Here is a pretty straight forward wiring diagram for the tortoise machines. this will throw the turnout back and forth and give you an LED indication of which what the turnout is thrown. You will need a Double Pole, Double Throw (no center off) switch (DPDT) and two LED's of you color choice (I use orange for mainlines and red for spurs), a power source and tortoise. The outer two pins of the switch machine control the motor. When the motor is stalled it acts as a resistor for the LED's so you don't need one in line with the circuit. This is the simplest method of showing position indication. if you have do not need to show position indication just don't put the LED's in line with the circuit. The LED's will go dim when the machine is moving but will brighten back up once it has stalled (thrown completely).

The DPDT has the outside terminals wired together in an X pattern (lower left connected to upper right, Upper Left connected to lower right). The center two poles connect to the outside pins of the switch machine.

While you can buy edge connectors to hook up to the tortoises, I don't bother with them since it is only two wires connected to the machine. I pre-solder about 10ft of wire (I use 1 pair of wires from network cable) to the machine and then install it in its desired location. No soldering under the layout.

I use this method for all my non-mainline turnouts on the layout. the mainline turnouts are connected to stationary decoders so the dispatcher as well as the local operator have control of the turnouts.