While I have not used Servos for switch machines I believe that they are quite a bit cheaper. Tam Valley has a controller that can drive up to 8 servos per board. here is a link to their site.

http://www.tamvalleydepot.com/products/octopusservodriver.html. I use tortoise switch machines. I have 1/2"- 1" Subroadbed and 1/4" Road bed on top of that. I use 0.039 Steel wire to make the link to the tortoise.

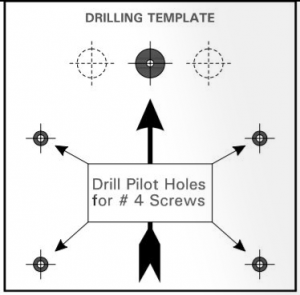

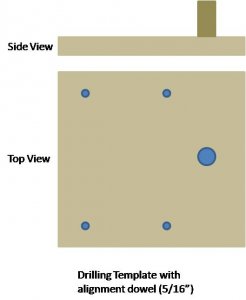

What I do is when laying turnouts I mark the center hole of the throwbar using a fine tip permanent marker. I then drill a 5/16" hole through the roadbed and subroadbed. I then lay the turnout. The hole is pretty much unnoticeable. I created a jig using the template provided with the tortoise instructions. I cut the template out and glued it to a 1/4" piece of plywood. I drilled out the mounting holes with a 1/16" bit and drilled the wire hole out (Black dot on image below) with the same 5/16" bit. I glue a 5/16" dowel in the hole. This make sure that the template lines up with the hole drilled in the subroadbed perfectly every time. The second image shows the completed jig.

View attachment 58128\

View attachment 58129

The 5/16" dowel is place into the hole drilled in the subroadbed and held in place by a finger while I drill the 4 mounting holes using the same 1/16" bit I used to make the jig. I then remove the jig and install 2 #4 screws on one side. I then install the tortoise machine (minus the wire) onto those two screws. I then use a third screw to secure the tortoise in place.

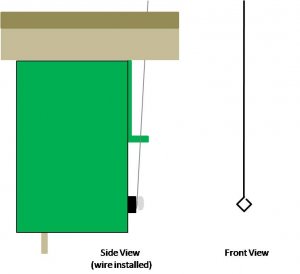

I buy 0.039 steel wire in 3 foot lengths as this seems to have the right amount of tension I need to be able to hold over my Peco/shinohara turnouts. I like it because I can also cut it to the length that I need. I drop the steel wire in from the top side of the layout through the throwbar hole. I then pass it through the green bar used to increase or decease the amount of torque on the wire. I then bend the end of the wire into a diamond shape (as seen in the image below) and secure it to the tortoise with the provided screw. This seems to be alot easier then trying to bend the wire to the shape given in the instructions and eliminate a lot of hassle. It jsut wraps around screw instead of trying to be pushed into a little tiny hole. The last thing I do is trim off the excess wire on the top side of the layout after cycling the machine back and forth a few time. Trim off the wire when it is on the one of the sides because if it is centered it is possible to cut the wire too short and it could pop out when you throw the turnout (ask me how i know,

) it takes me about 10 minutes to get a machine installed and fully wired up. I hope this helps.

View attachment 58130