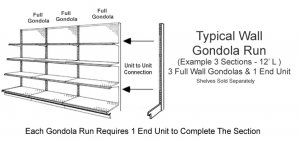

Gondola Shelving

I was just in my local Harbor Freight store this evening and I began to look at their metal shelving. Its pretty damn sturdy, while not being to intrusive with its size of supports. I came home and decided to look up commercial shelving. It turns out the what i saw is general referred to 'gondola shelving'.

1) The support arms are of various lengths (the ones I saw holding up considerable weight o the shelves) were up to 21 inches long, and then 17 inches long. They are of a low profile that would not interfere with a dbl-deck layout.

2) There is a nice thin perforated metal deck as a shelf that might only need a nice foam topping.

3) The upright support beams might well be set in next to the layout rooms stud walls.

4) In my case the studing is on 24; centers, and a lot of this shelving appears to be 48' wide.

...just got me to thinking that this type of shelving could be cut down and modified to provide the sub-roadbed and shelf functions in lieu of our relatively thick plywood subroadbed with bracket supports.

http://www.usedgondolashelving.com/

...and a considerable amount of the shelving might be found on the used market?

http://www.usedgondolashelving.com/Florida_shelving.html

I was just in my local Harbor Freight store this evening and I began to look at their metal shelving. Its pretty damn sturdy, while not being to intrusive with its size of supports. I came home and decided to look up commercial shelving. It turns out the what i saw is general referred to 'gondola shelving'.

1) The support arms are of various lengths (the ones I saw holding up considerable weight o the shelves) were up to 21 inches long, and then 17 inches long. They are of a low profile that would not interfere with a dbl-deck layout.

2) There is a nice thin perforated metal deck as a shelf that might only need a nice foam topping.

3) The upright support beams might well be set in next to the layout rooms stud walls.

4) In my case the studing is on 24; centers, and a lot of this shelving appears to be 48' wide.

...just got me to thinking that this type of shelving could be cut down and modified to provide the sub-roadbed and shelf functions in lieu of our relatively thick plywood subroadbed with bracket supports.

http://www.usedgondolashelving.com/

...and a considerable amount of the shelving might be found on the used market?

http://www.usedgondolashelving.com/Florida_shelving.html

Attachments

Last edited by a moderator:

![IMAG0160_BURST002[1].jpg IMAG0160_BURST002[1].jpg](https://modelrailroadforums.com/forum/data/attachments/16/16074-d548e9db4b0b150737c80c74c385b29b.jpg)