Wrapping model railroad razor wire around a tube or dowel is just the way I would do it too, the advantage of the metal tube being that you can more easily slide it off. If I think about it, the only instances I've even seen of razor wire in the real world ARE rolled, although usually atop a fence in order to keep people outside from coming in, rather than as might used at Folsom Prison.

But this is about barbed wire, or at least this short talk about. Apologies for hijacking your thread if I've done so.

I mentioned four methods, and three of them probably depend on the fact that barbed wire is not just one, but two spiraled strands.

So, let's assume, in my case, and where my recently acquired, very thin nichrome wire is concerned, the first thing I would hope to do would be to take off some, if not all, of the shine. Make it look more galvanized. Spriral wrap it makes two twisted strands (this is probably important for three of my four methods.) Chemical etch for that first bit--painting it just makes it too thick, which defeats the whole idea behind using super-fine wire in the first place. In N-scale, paint thickness and grain sizes are more important, IMO, than in the larger scales. Part of the tradeoff--the larger scales can demand, at times, details we might not actually see in N-scale.

[Maybe things like barbed wire? Yeah...maybe things like barbed wire.

]

#1: Paint the stranded wire. Thin paint, and just far enough off the base etched color that it catches the eye to cause a double-take. To see the thin, painted "stripe" as just slightly different in color. "Hey...is that actually barbed wire there?"

To do that requires some sort of cleanable mask. Something etched, which can be used over and over. Thin lines, the rest blocked. Something like this:

https://www.amazon.com/Calligraphy-Measuring-Journaling-Invitations-2Pcs-Straight/dp/B09TNXJVNV/ref=sr_1_12?crid=G5XLOJBLXM5H&keywords=fine+dimension+dimensional+drawing+template&qid=1677065163&sprefix=fine+dimension+dimensional+drawing+template,aps,99&sr=8-12

This is another one, but designed only for precision dimensional layout:

https://www.amazon.com/Precision-Woodworking-Stainless-Positioning-Carpenter/dp/B08W3KP7C7/ref=sr_1_11?crid=3KWFCARSD5E8L&keywords=fine+dimension+marking+tools&qid=1677067442&sprefix=fine+dimension+marking+tools,aps,103&sr=8-11

I'm almost certain I've seen tools like that which use slots, and not just points. Just can't find 'em now, but I think you get the idea.

These tools are designed for use with thin lead pencils, but there are metal plate versions which are designed to make allow for fine line differentials for architectural pencils. 1/64" or so. The idea would be to used one of them as a mask for painting small "stripes"...just enough different in color to cause that double take. Put a bunch of wires stretched alongside one another, cross them with a mask something like that, and spray. See what you get. And the mask could be cleaned and used again, if it was a one piece thin metal.

Of course you could also have such a fine mask photo etched. Almost certainly the better choice. Or etch one yourself.

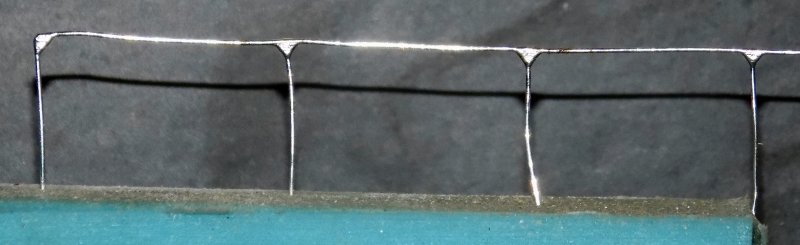

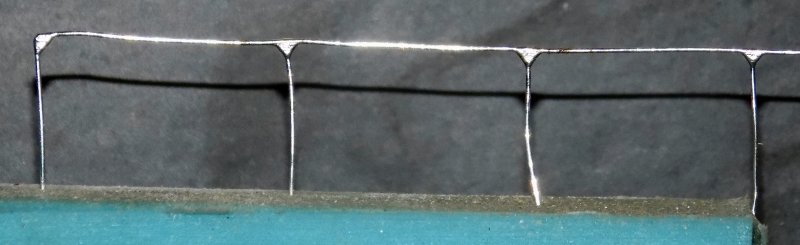

#2: wind the double strands back and forth around pins on a build/paint jig, to whatever length you choose. 15"=200' sections in N-scale, etc.

Then cross them with single strands (also around pins). US barbed wire runs between 6" and 9" between barbs, as best I can tell. A bit of upward tension on the base (long) wires, and a bit of downward tension on the cross "barbs" should bring them into direct contact with one another. At which point you can (hopefully) fasten one set to the other.

Two ways I see to do that: Solder, the idea being that the melted solder "wicks" along the double stranded wires and thereby connect and (hopefully) hold the crossed "barbs' in place.

#3: Same as above, except use thinned out cyanoacrylate, which might/should "wick" out in same way as the solder.

The wicking effect I mention is capillary attraction, in the same way water can slip under a flat plate, etc. Or in the same the thinned down water/liquids we often use to wet our track ballasts to allow thin adhesives to hold them in place. I THINK the wicking effect would only work because of the two strands, which would draw the solder or fluid along the primary strand. It MIGHT work too with a single strand base, but I would guess probably not. And it's the wicking effect which keeps you from having to solder each joint individually....

[Which would be a particular niche in...He**l

#4: Use photographs of flat fencing, with clear openings, just where they would be on the original. Photographic modeling...using photo prints or slide bases can make simple prints look like very highly detailed models. The well known RPI New England Berkshire and Western club used some prints like these to give the illusion of finely crafted models, albeit not quite in the forground. You do reach a point up close where the fact that it's a photo print gives the game away, yes. Photo prints also have a shine, which can be a problem. But a bit further back, no one is likely to notice, let alone ask.

----

That said, I also saw some roads on a layout which had my jaw dropping as to their real-world appearance. Just amazing.

Then the modeler gave the technique away--the roads were PHOTOS of real roads he had shot using a drone pointed downward, and then printed and put in place. Just brilliant, I thought, and I immediately bought a twin pack of drones for just that purpose. Haven't tried it yet, but I'll post if it works out.

[DJ/Ken should try this first. He's a licensed drone pilot after all, and his downward videos make it clear how well it could work for him]

I have a couple other uses too for my own drones, but I cant get up to the mountains until spring to try 'em out. We'll see how it works out.

We really do need to talk

We really do need to talk

modelrailroadforums.com

modelrailroadforums.com

20200329_211942 by Chuck Lee, on Flickr

20200329_211942 by Chuck Lee, on Flickr