flyboy2610

Loveably weird

My turnouts arrived!

I got the first row of cork tiles installed. I ran out of paint so I need to get some more.

so I need to get some more.

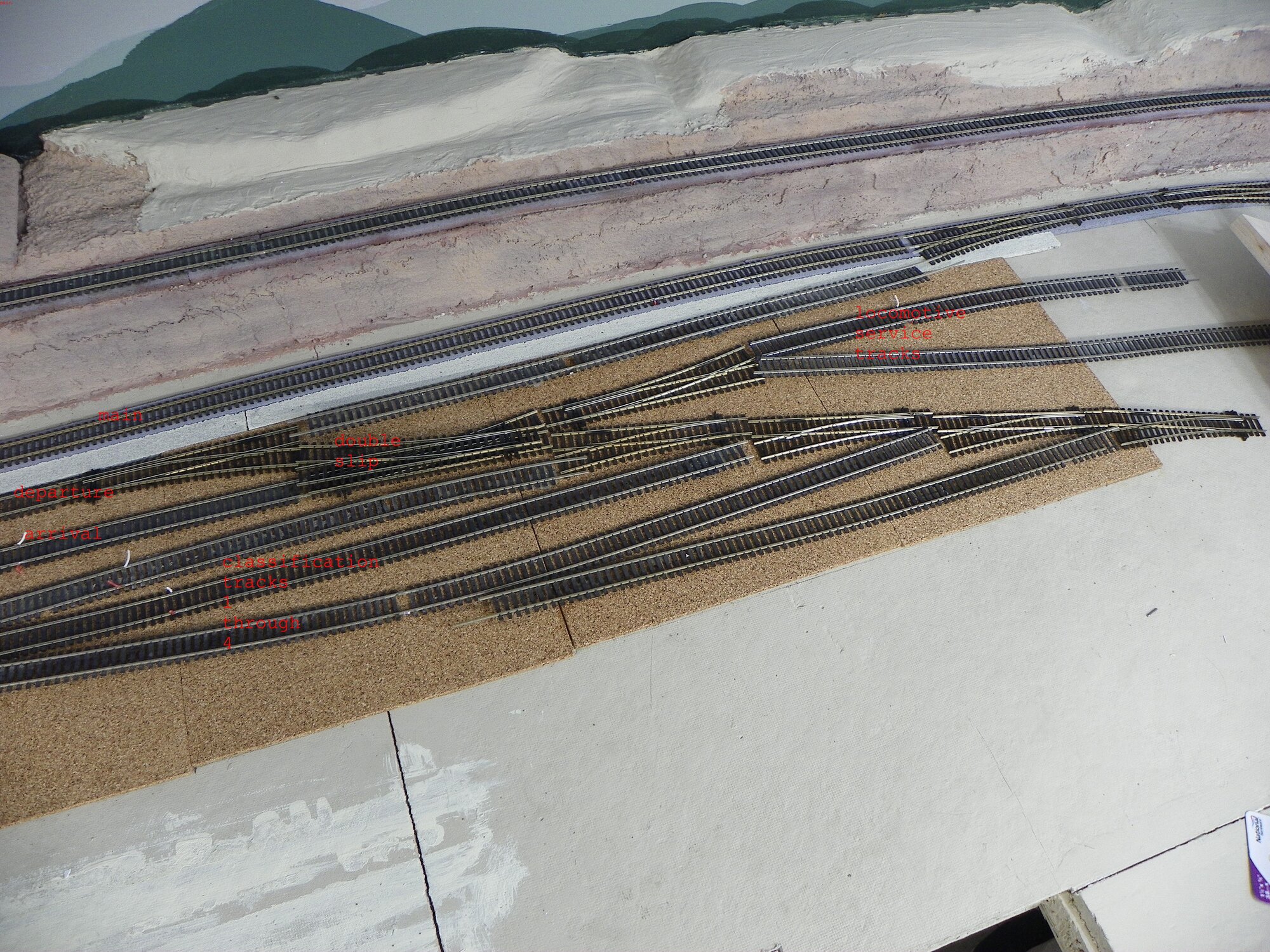

I took a good long look at the way I had planned to lay out the yard, and decided it needed to be redone. Basically, I moved the classification tracks from the south end of the yard to the north end. I also rearranged some turnouts. I did this to make it more efficient for the yard switcher to pull cars from the arrival track (I also made separate arrival and departure tracks). This layout will also make it more efficient to stage cars on the departure track.

I thought I had more new flex track, but I guess I'm out, so some old ratty Atlas track is doing stand-in duty in these pics. I also need to get a Peco code 100 double slip, more on that later.

Here's a pic of the north end of the yard. The tracks are, from the top, the outer main, the inner main, the departure track, the arrival track, and classification tracks 1 through 4.

(Sorry about the text font being so light. I changed it in the following pics.) The double slip (here represented by a couple of turnouts) will enable an incoming locomotive to cut off from his train and transit to the locomotive service tracks. If the train is only stopping to change power, it will stop on the departure track. The locomotive can still cut off, and the new locomotive can back off the service track, through the double slip, and hook onto the train. The train can then head out on the main. The yard switcher can use the double slip to access both the arrival and departure tracks to break down a train and build up a new one. The drill track, not shown, will simply extend off to the right from the end of the yard ladder.

Here's a pic of the middle of the yard. Not much there, yet.

And a pic of the south end of the yard. An incoming train will use the turnout on the left to enter either the arrival or departure track, depending on what it's doing. If it's just a power swap it will go on the departure track. If the train is terminating here, it will go on the arrival track. The diverging route of the second turnout will lead to the caboose track. The two turnouts forming a crossover will allow the switcher to get a caboose from the caboose track, then back it onto the departure track without having to get onto the main line.

That's my story and I'm stuck with it.

The space in the foreground will be used for things like a RIP track, shop, and I think I'll put the icing platform down there somewhere as well. Things are subject to change, you know how that goes.

I don't plan to run super long trains, maybe 6 to 6-1/2 feet in length. Although I am curious as to how many cars my Athearn Genesis Big Boy can pull up that 2% grade on a curve..... I'll be sure to post a video when that experiment happens.

I got the first row of cork tiles installed. I ran out of paint

I took a good long look at the way I had planned to lay out the yard, and decided it needed to be redone. Basically, I moved the classification tracks from the south end of the yard to the north end. I also rearranged some turnouts. I did this to make it more efficient for the yard switcher to pull cars from the arrival track (I also made separate arrival and departure tracks). This layout will also make it more efficient to stage cars on the departure track.

I thought I had more new flex track, but I guess I'm out, so some old ratty Atlas track is doing stand-in duty in these pics. I also need to get a Peco code 100 double slip, more on that later.

Here's a pic of the north end of the yard. The tracks are, from the top, the outer main, the inner main, the departure track, the arrival track, and classification tracks 1 through 4.

(Sorry about the text font being so light. I changed it in the following pics.) The double slip (here represented by a couple of turnouts) will enable an incoming locomotive to cut off from his train and transit to the locomotive service tracks. If the train is only stopping to change power, it will stop on the departure track. The locomotive can still cut off, and the new locomotive can back off the service track, through the double slip, and hook onto the train. The train can then head out on the main. The yard switcher can use the double slip to access both the arrival and departure tracks to break down a train and build up a new one. The drill track, not shown, will simply extend off to the right from the end of the yard ladder.

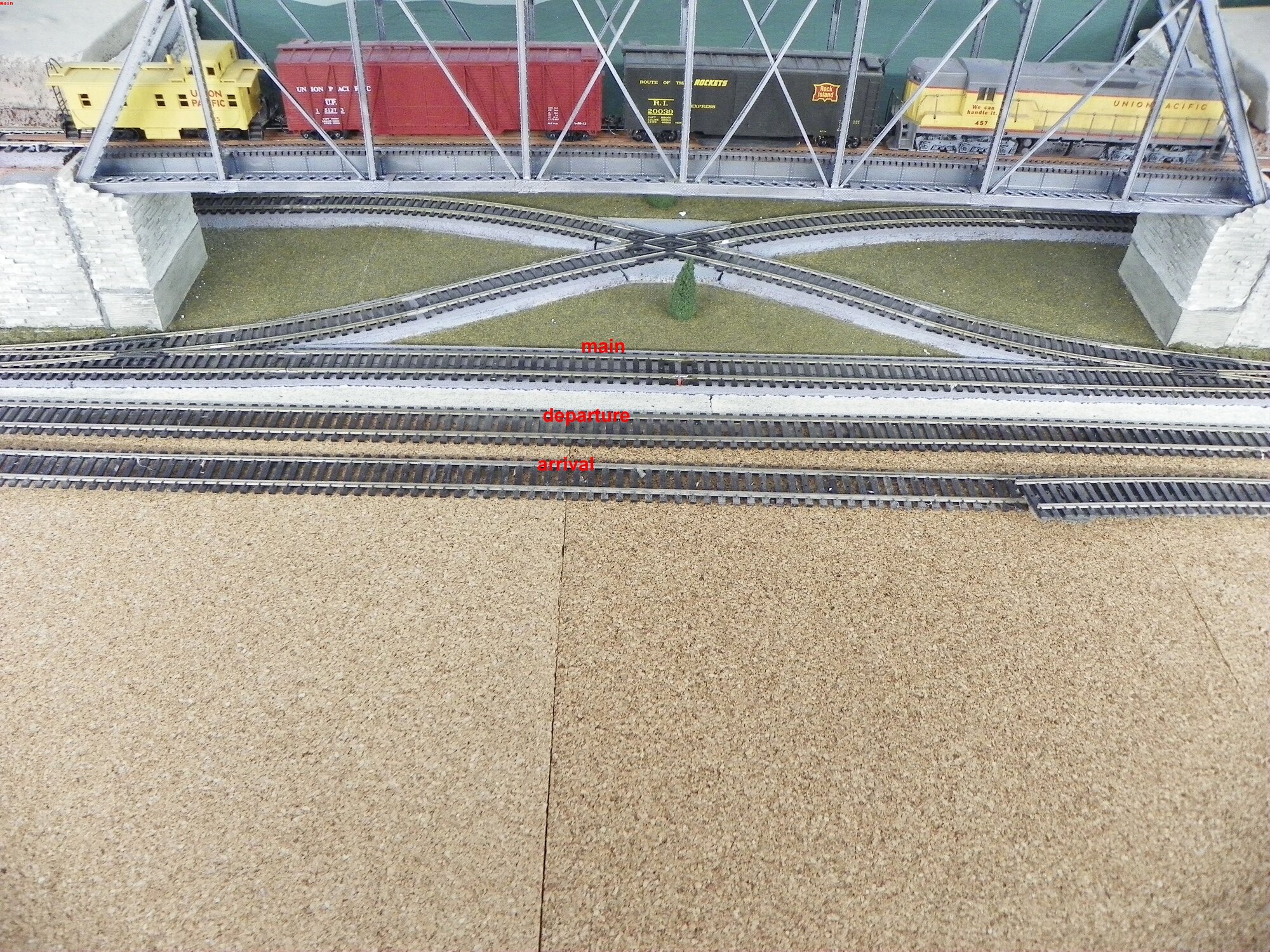

Here's a pic of the middle of the yard. Not much there, yet.

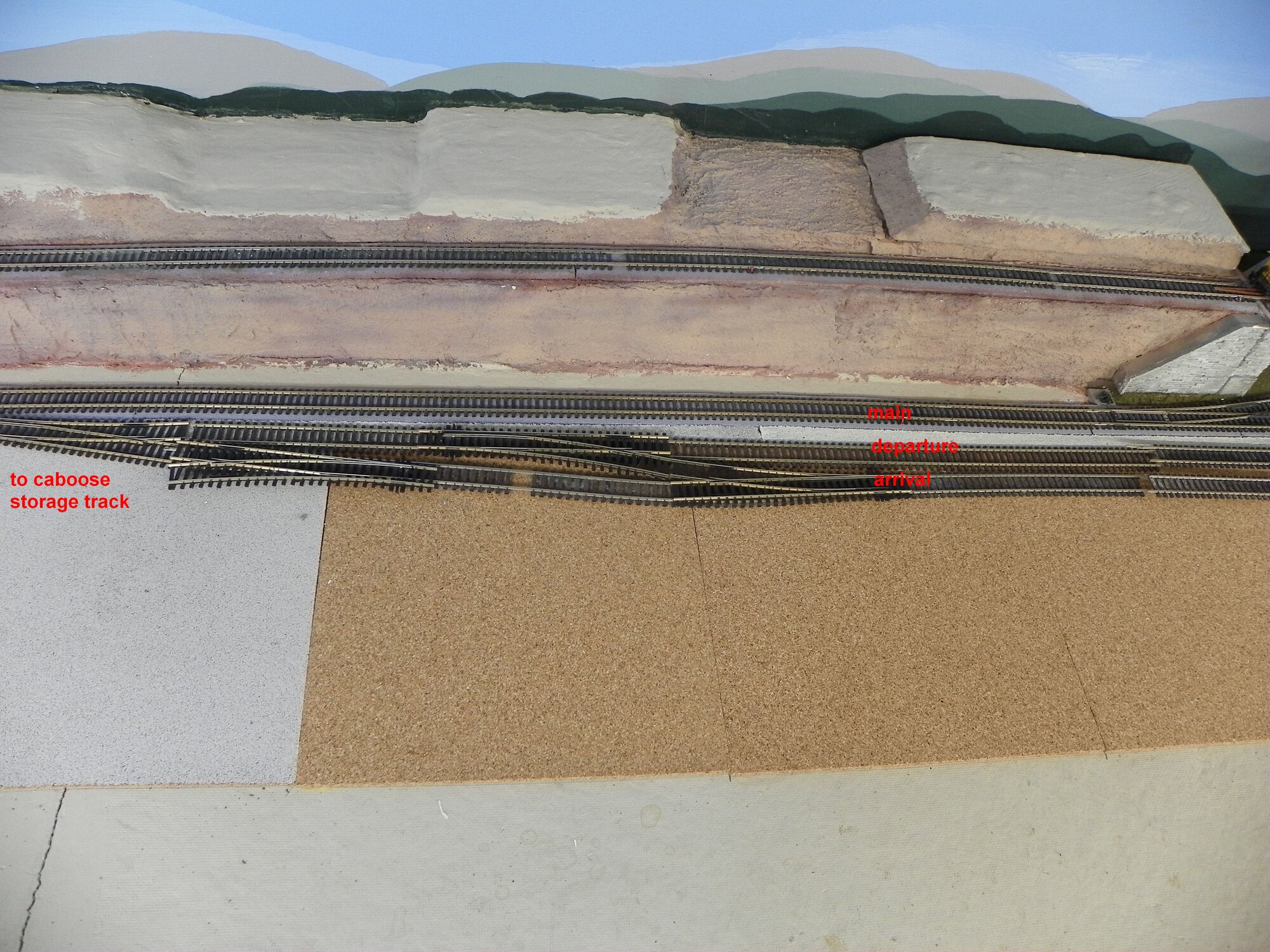

And a pic of the south end of the yard. An incoming train will use the turnout on the left to enter either the arrival or departure track, depending on what it's doing. If it's just a power swap it will go on the departure track. If the train is terminating here, it will go on the arrival track. The diverging route of the second turnout will lead to the caboose track. The two turnouts forming a crossover will allow the switcher to get a caboose from the caboose track, then back it onto the departure track without having to get onto the main line.

That's my story and I'm stuck with it.

The space in the foreground will be used for things like a RIP track, shop, and I think I'll put the icing platform down there somewhere as well. Things are subject to change, you know how that goes.

I don't plan to run super long trains, maybe 6 to 6-1/2 feet in length. Although I am curious as to how many cars my Athearn Genesis Big Boy can pull up that 2% grade on a curve..... I'll be sure to post a video when that experiment happens.