videobruce

Tower Operator

First off a little background on myself. I'm a operating kind of guy. As a former brakeman, dispatcher office operator, Tower Operator I like operation. Not really interested in industrial switching. Necessities are;

1. Double track,

2. Long sidings,

3. Plenty of interlockings,

4. A hump yard,

5. A passenger station,

6. A engine house and facilities,

7. Two levels,

8. Around the wall with accessibility without openings in the layout.

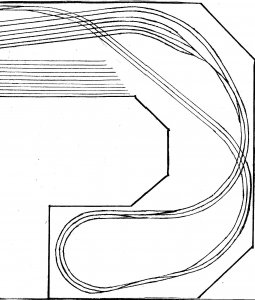

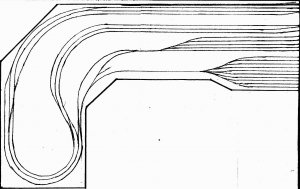

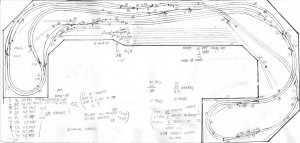

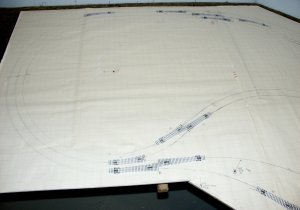

Most of this has been thought of in the attached drawing (left and right side since it is a wide image and the restriction of photo size for attachments.

The yet to be built room will be 10x23' in a un-finished basement with a stone foundation. One wall will be the foundation (open, no layout except for a short portion). The built walls (all wood, no cheap drywall) will have the layout in a 'self' like design. The basement get very humid anytime it rains, especially in the spring (varies from as low as 40% to close to 100%). I will have a dehumidifier for that enclosed room. I'm hoping by somewhat isolating the room on three sides and partially enclosing the ceiling I will have a handle on humidity. There is no issue in the winter other than temperature (varies from 40-45 degrees to close to 80 degrees).

Other than the humidity, am I going to have a issue with 'heat kinks' and/or pull aparts?? Those figures are extremes. Temp. ranges from close to upper 40's to upper 70's. High humidity is usually short lived, except under long rainy periods (mostly in the spring).

I talked to a modeler locally in HO scale and he had problems with pull-aparts & heat kinks. But, that was in HO. Is N more or less prone to this?

My first (real) layout was a 5x7' modified 'L' shaped table in a bedroom. For a 1st (real) layout, my major resign fault was excessive grades, especially for the hump. Damn MicroTrains trucks allowed the cars to literally crash into the bumpers at the ends of the tracks sometimes on to the floor. One excessively sharp curve at the top of the grade caused straight-lining with longer trains due to the grades. I have close to 250 freight & passenger cars all with MT trucks & couplers. My power rooster is 23 freight & passenger (Atlas & Life Like), all diesel. No DCC.

This includes a elevated portion that will include a passenger station with siding off either main. No, there is no 'coach yard' as I don't seem to have room for it without actually seeing it in 3d (after the table frame is built and can visualize the look as it is planned now).

The hump & receiving yard has a engine facilities. I changed the location of the facilities a couple of times and as it stands it needs to be change again since I don't like tracks on either side of the receiving yard 'lead'.

Table depth is limited to three feet since I'm concerned about access along the long wall. I don't want to reduce the depth to 30" since it will 'cram' all of the too close together. It's alot as it is.

1. Double track,

2. Long sidings,

3. Plenty of interlockings,

4. A hump yard,

5. A passenger station,

6. A engine house and facilities,

7. Two levels,

8. Around the wall with accessibility without openings in the layout.

Most of this has been thought of in the attached drawing (left and right side since it is a wide image and the restriction of photo size for attachments.

The yet to be built room will be 10x23' in a un-finished basement with a stone foundation. One wall will be the foundation (open, no layout except for a short portion). The built walls (all wood, no cheap drywall) will have the layout in a 'self' like design. The basement get very humid anytime it rains, especially in the spring (varies from as low as 40% to close to 100%). I will have a dehumidifier for that enclosed room. I'm hoping by somewhat isolating the room on three sides and partially enclosing the ceiling I will have a handle on humidity. There is no issue in the winter other than temperature (varies from 40-45 degrees to close to 80 degrees).

Other than the humidity, am I going to have a issue with 'heat kinks' and/or pull aparts?? Those figures are extremes. Temp. ranges from close to upper 40's to upper 70's. High humidity is usually short lived, except under long rainy periods (mostly in the spring).

I talked to a modeler locally in HO scale and he had problems with pull-aparts & heat kinks. But, that was in HO. Is N more or less prone to this?

My first (real) layout was a 5x7' modified 'L' shaped table in a bedroom. For a 1st (real) layout, my major resign fault was excessive grades, especially for the hump. Damn MicroTrains trucks allowed the cars to literally crash into the bumpers at the ends of the tracks sometimes on to the floor. One excessively sharp curve at the top of the grade caused straight-lining with longer trains due to the grades. I have close to 250 freight & passenger cars all with MT trucks & couplers. My power rooster is 23 freight & passenger (Atlas & Life Like), all diesel. No DCC.

This includes a elevated portion that will include a passenger station with siding off either main. No, there is no 'coach yard' as I don't seem to have room for it without actually seeing it in 3d (after the table frame is built and can visualize the look as it is planned now).

The hump & receiving yard has a engine facilities. I changed the location of the facilities a couple of times and as it stands it needs to be change again since I don't like tracks on either side of the receiving yard 'lead'.

Table depth is limited to three feet since I'm concerned about access along the long wall. I don't want to reduce the depth to 30" since it will 'cram' all of the too close together. It's alot as it is.

Attachments

Last edited by a moderator: