Hi

I have kind of stalled in my layout build. I'm not sure how to control the points, my baseboard is 50mm XPS foam glued to 3mm ply.

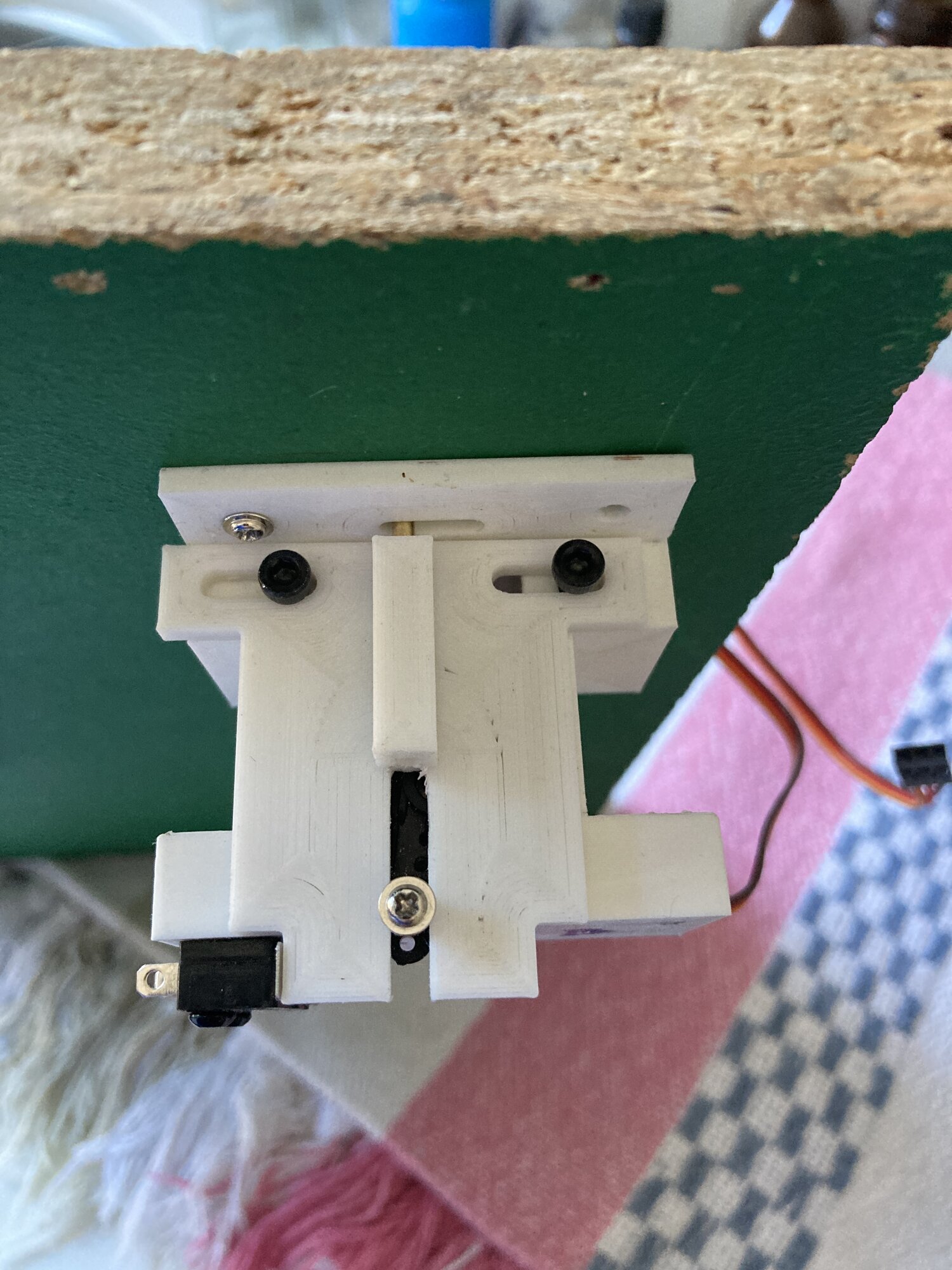

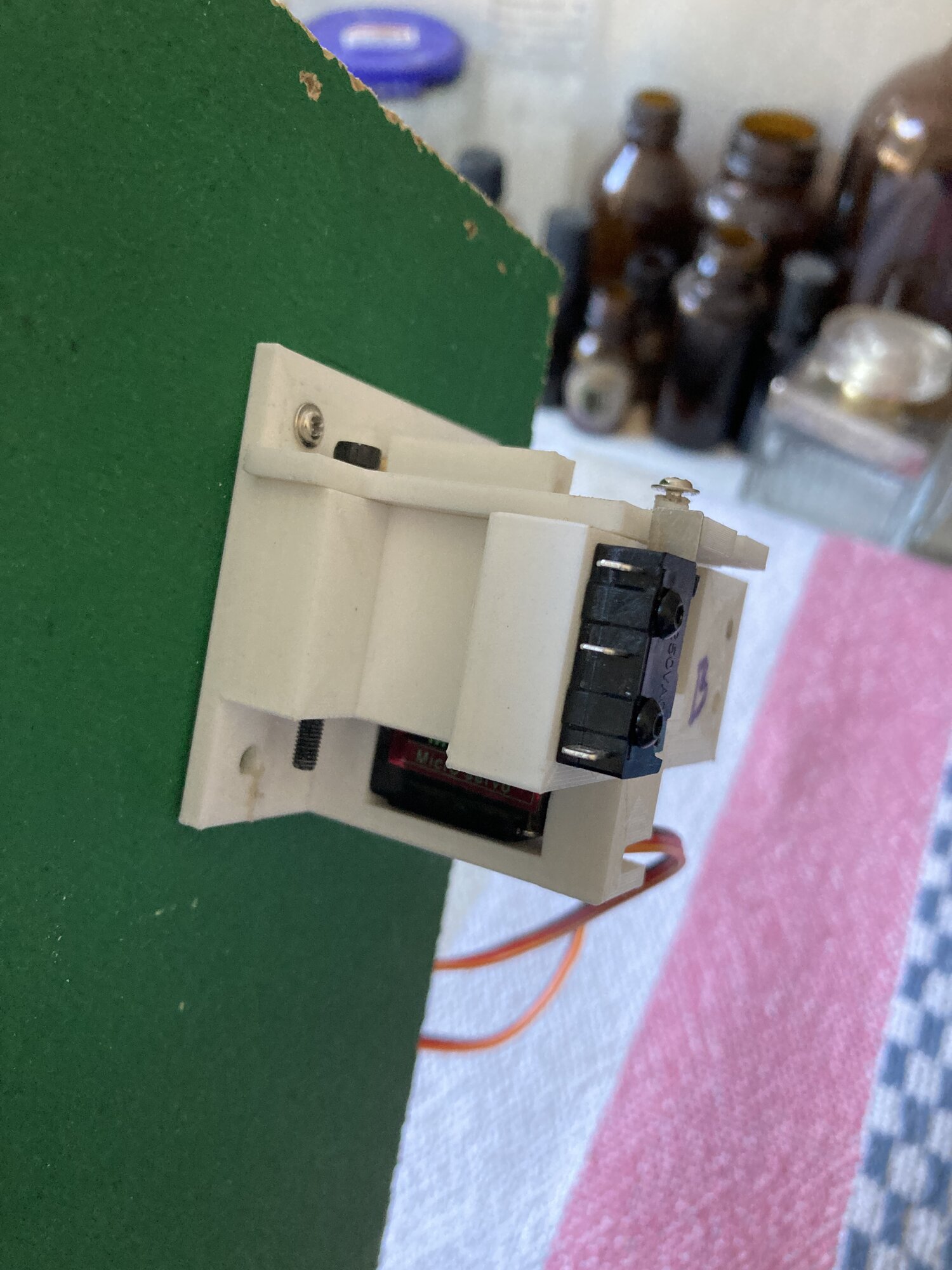

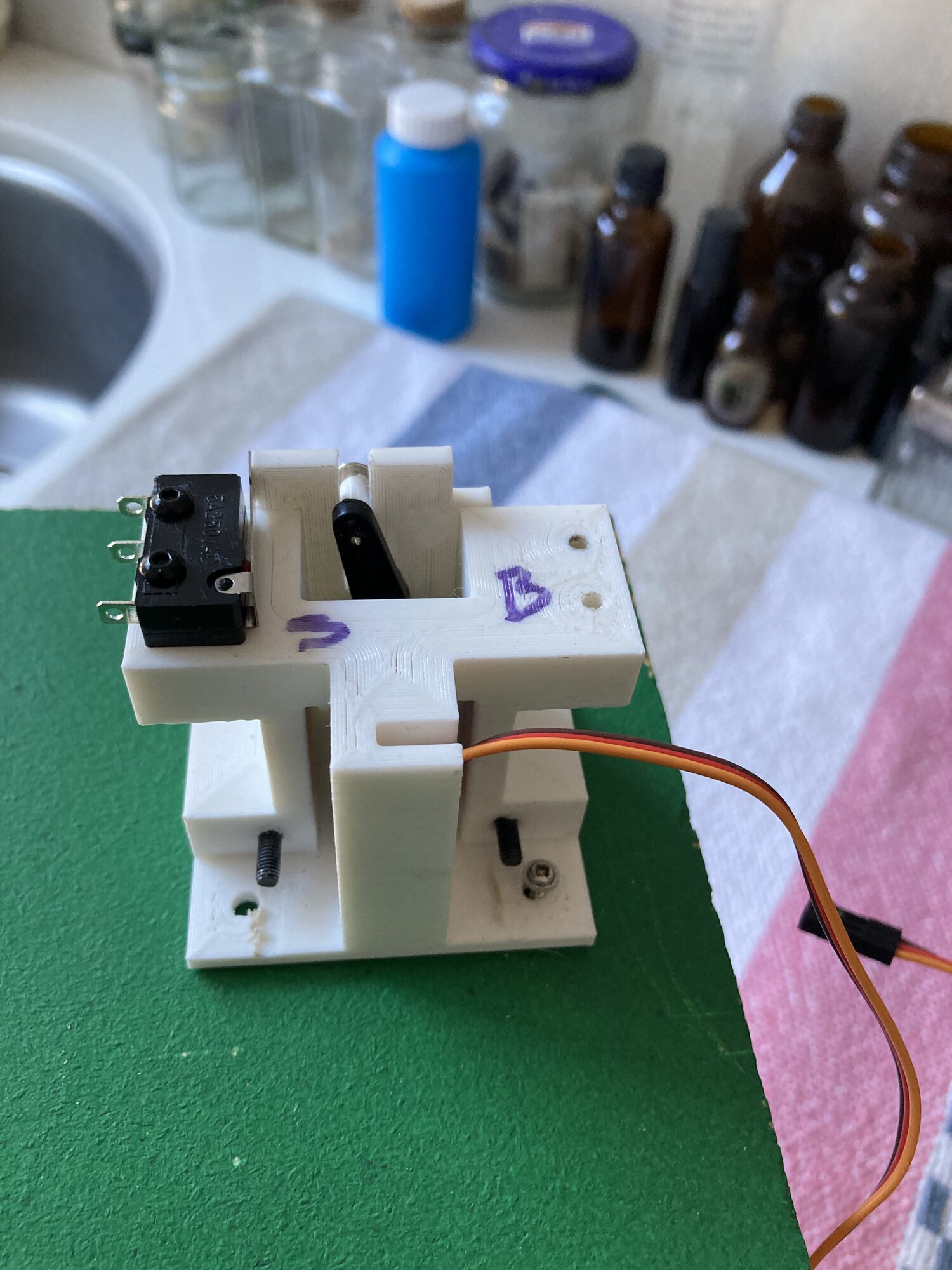

I was going to control the points with servos and arduino, I have modelled a linear actuator, so I could mount the servo off to the side and hide the wire under a 3D print point motor.

I have tested this on a 12mm board and it seams to work fine when the piano wire goes through the hole in the point, it kind of works when it the wire goes under the track towards the point motor.

The issue I have is how to install the linear actuator to the baseboard, from the underside of the baseboard to the top of the sleepers varies from 60 to 90mm, which maybe way to much for the piano wire to handle without bending. I have thought about using a bass tube with piano wire placed inside and soldered or glued in place to make it more rigid.

I was wondering how others may have installed point motors when using XPS foam, unfortunately I have laid the cork roadbed, which adds to the woes. I'm a bit hesitant to cut a big hole in the foam to place the whole point motor, but open to ideas.

Yes I have over engineered this.

Cheers

I have kind of stalled in my layout build. I'm not sure how to control the points, my baseboard is 50mm XPS foam glued to 3mm ply.

I was going to control the points with servos and arduino, I have modelled a linear actuator, so I could mount the servo off to the side and hide the wire under a 3D print point motor.

I have tested this on a 12mm board and it seams to work fine when the piano wire goes through the hole in the point, it kind of works when it the wire goes under the track towards the point motor.

The issue I have is how to install the linear actuator to the baseboard, from the underside of the baseboard to the top of the sleepers varies from 60 to 90mm, which maybe way to much for the piano wire to handle without bending. I have thought about using a bass tube with piano wire placed inside and soldered or glued in place to make it more rigid.

I was wondering how others may have installed point motors when using XPS foam, unfortunately I have laid the cork roadbed, which adds to the woes. I'm a bit hesitant to cut a big hole in the foam to place the whole point motor, but open to ideas.

Yes I have over engineered this.

Cheers