Latest update

We just had another operating session yesterday. We did no track cleaning beforehand and only cleaned the wheels on a handful of locomotives out of a fleet of 70 or more. Electrical pickup was only a problem on a few light switchers and a Budd car with brass wheels, and only on dead frog turnouts.

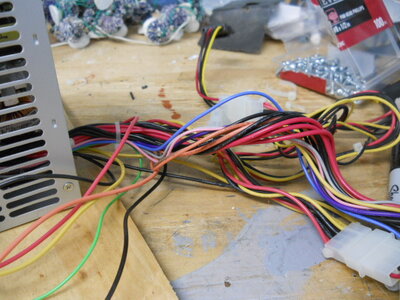

I talked to one yard operator and he mentioned having trouble on two turnouts with dead frogs on the yard lead. I carefully applied graphite to the powered parts of those turnouts and he later said there was no problem on them anymore. He did complain of a lot of trouble switching the freight shed, though. When I checked the shed trackage, I discovered a couple broken feeders on point rails--no amount of graphite will save you when no power gets to the locomotive.

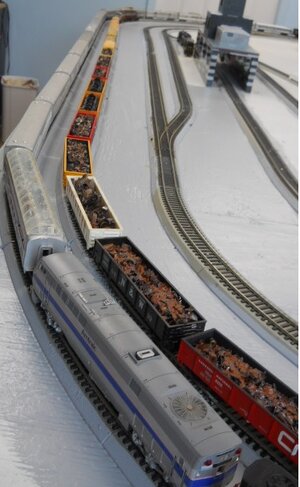

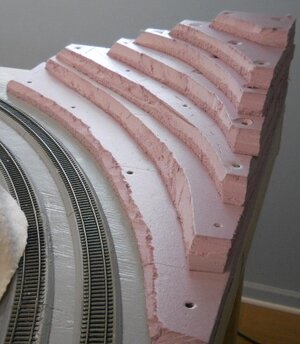

We run 40 car freights up several helices with grades of between 1.6 and 2 percent. We run 3 or 4 diesels on them; they had no traction problems. We used to have spinning wheels with No-Ox at times on the same trains. Even locomotives which used to be considered problem children ran flawlessly. I can't say there were no problems, but electrial pickup was not one of them. It was a pleasure to run the layout, and with a fraction of the pre-session maintenance.

Frankly, if I'm impressed, it has to be good.

--------------

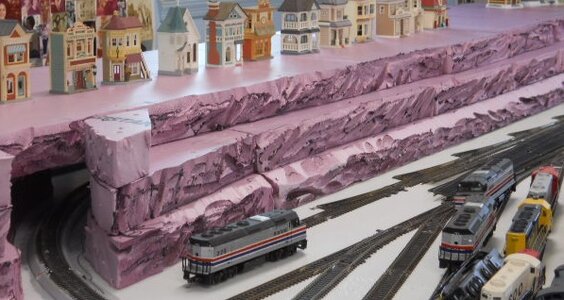

I can see where someone with a smaller layout and easily accessible track and a nice clean layout room could follow the magic No-Ox procedure to the letter and get good results. Our layout is in a converted barn/quanset hut and it took weeks of occasional effort to get to all the track with No-Ox. Applying it was difficult and frustrating and it was hard to keep track of where it had been applied and where it had been wiped off, etc. It was too complicated and in the end, ineffective.

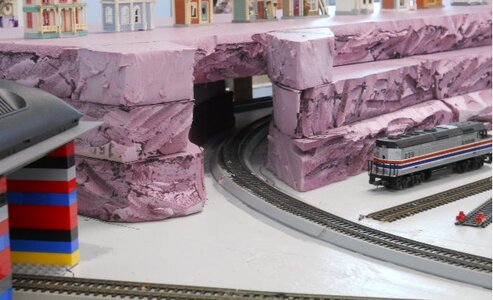

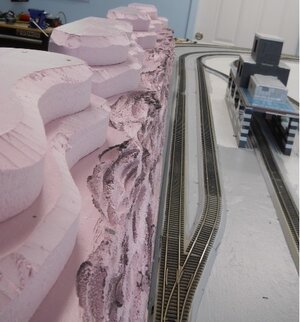

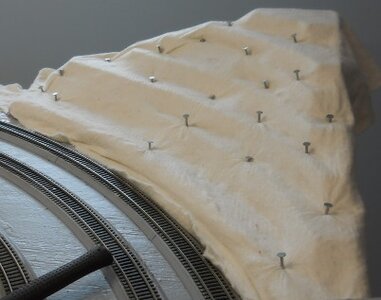

The problem we had with No-Ox was on mulitple levels. First, our layout is pretty big, and mostly handlaid track. Trying to apply No-Ox to the railhead was laborious, and the cloths we used snagged on the spike heads all the time. It was hard to get into deeper areas of the layout and some of the hidden track was inaccessible to this sort of effort.

We also made the mistake of doing a major cleanup after we applied the No-Ox which kicked up quite a bit of dust. The dust seemed to get stuck on the rails afterwards and made operation worse than before we applied the No-Ox. We did try cleaning all the track, but it didn't seem to help. The layout simply didn't run any better after all that effort, and in some cases units which ran well before started giving us problems.

We did all sorts of work on them to fix them and couldn't solve the issues. In some cases they were brand new locos with only a few sessions on them. It was frustrating. Now that the No-Ox is no longer being applied, and in most areas has been removed by track cleaning work, and graphite is being more or less randomly applied, these same units work flawlessly--with no other work done on them. It's almost eerie, how well everything runs. When you get used to sound units cutting out constantly for no good reason, it's strange to have them run perfectly now.

The contrast between having to clean the wheels on every locomotive during our staging sessions, as well as run track cleaning trains up and down all the mainline and hand cleaning the track with abrasives (wrecking trackside detail as we go, naturally) to now doing none of these things and getting better operation than we did with all the effort is remarkable. I was skeptical at first, too, but I am definitely a believer now.

Try it, it doesn't cost much and is easy to do. It doesn't get any better than that.

Jurgen