GuilfordRailman

Well-Known Member

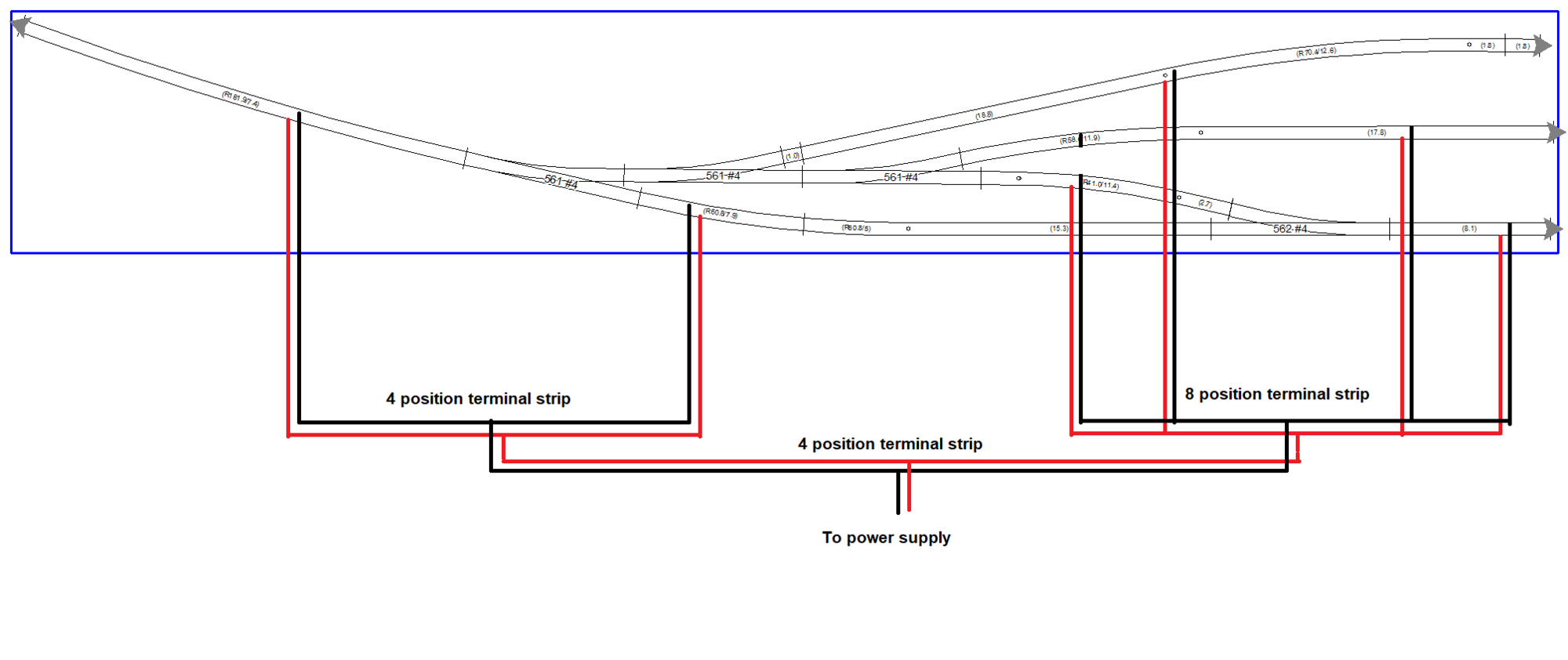

I will be starting track work soon on my 1 ft x 6.5 ft HO scale shelf switching layout and need some help with understanding the difference in wiring gauges and which is best for my setup. I lack knowledge in this area and could use some help. Here is a basic schematic showing how many feeders I plan to wire into the track plan:

The layout is going to be DC and is meant to be portable and therefore splits into two sections. There is a 4-position terminal strip for the left section and an 8-position terminal strip for the right section. The other 4-position terminal strip is for connecting the wiring from both the other terminal strips into one that can be easily connected/disconnected using spade connectors. Finally, the main power supply will feed into the bottom 4-position terminal strip as seen above. My main questions are what gauge wire should I use for the main power supply, and what gauge should I use for the feeders? I was thinking 24-gauge for the feeders and maybe 18 for the main power supply. Any thoughts?

The layout is going to be DC and is meant to be portable and therefore splits into two sections. There is a 4-position terminal strip for the left section and an 8-position terminal strip for the right section. The other 4-position terminal strip is for connecting the wiring from both the other terminal strips into one that can be easily connected/disconnected using spade connectors. Finally, the main power supply will feed into the bottom 4-position terminal strip as seen above. My main questions are what gauge wire should I use for the main power supply, and what gauge should I use for the feeders? I was thinking 24-gauge for the feeders and maybe 18 for the main power supply. Any thoughts?