KriegslokBR52

Well-Known Member

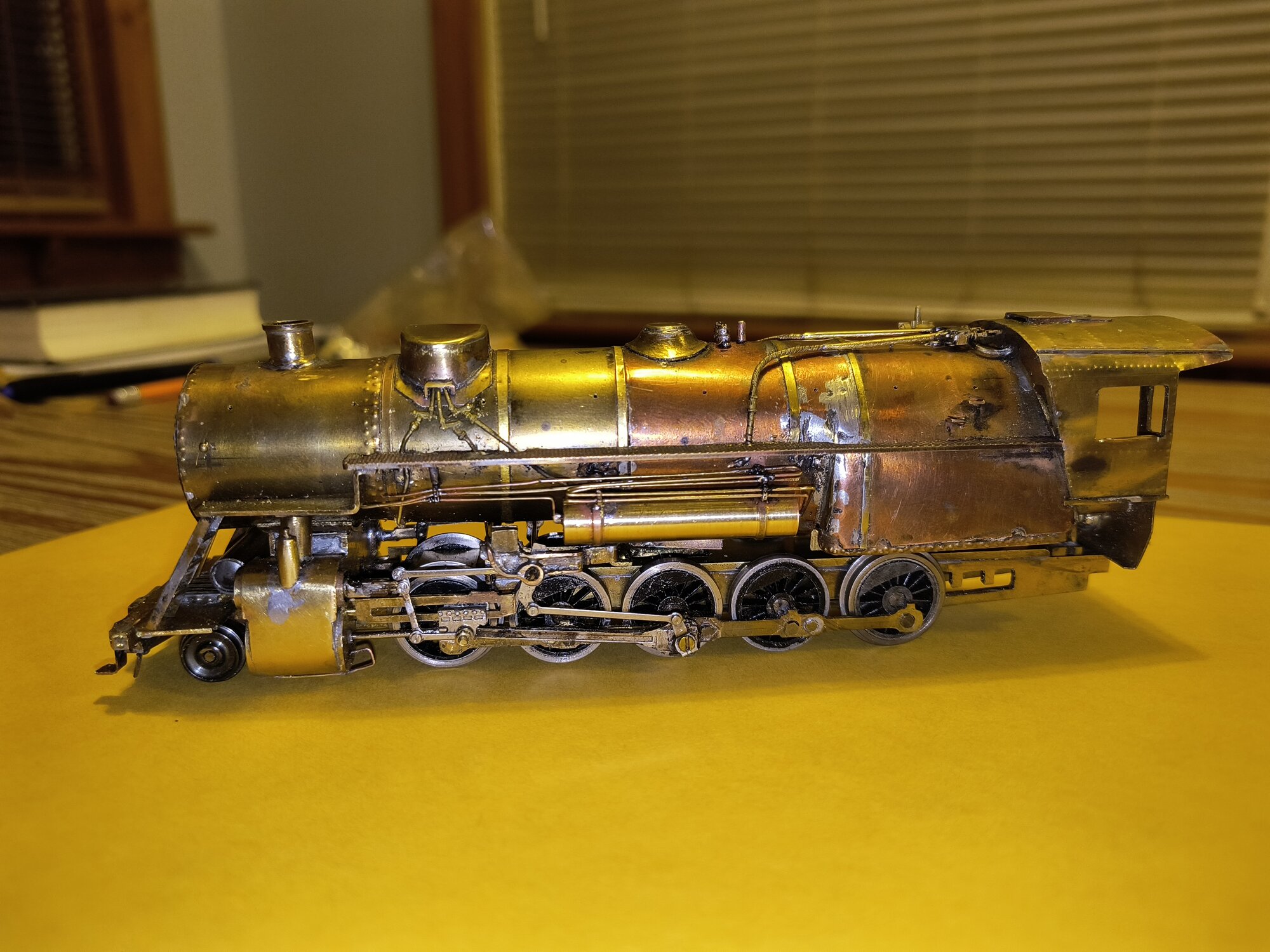

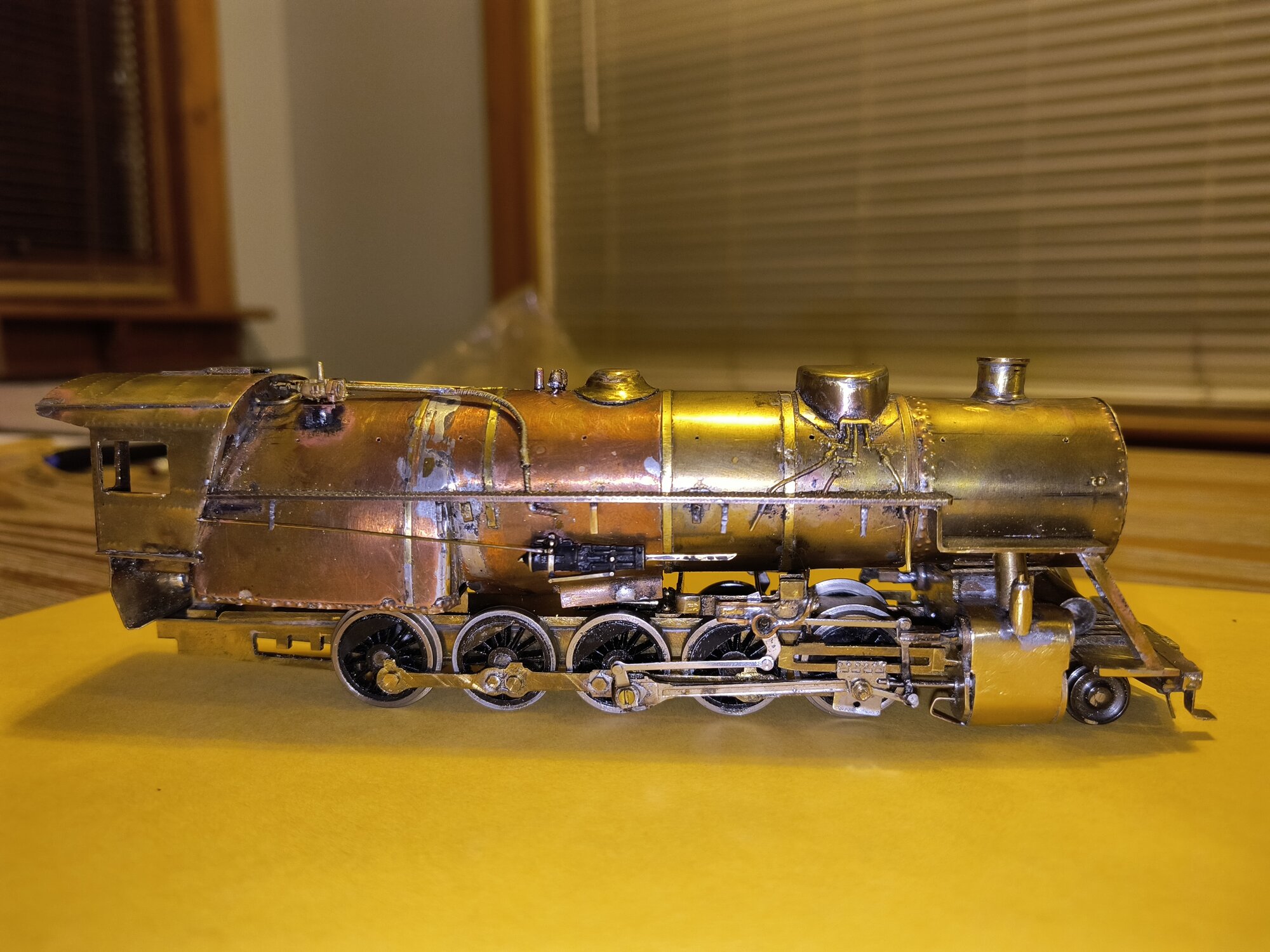

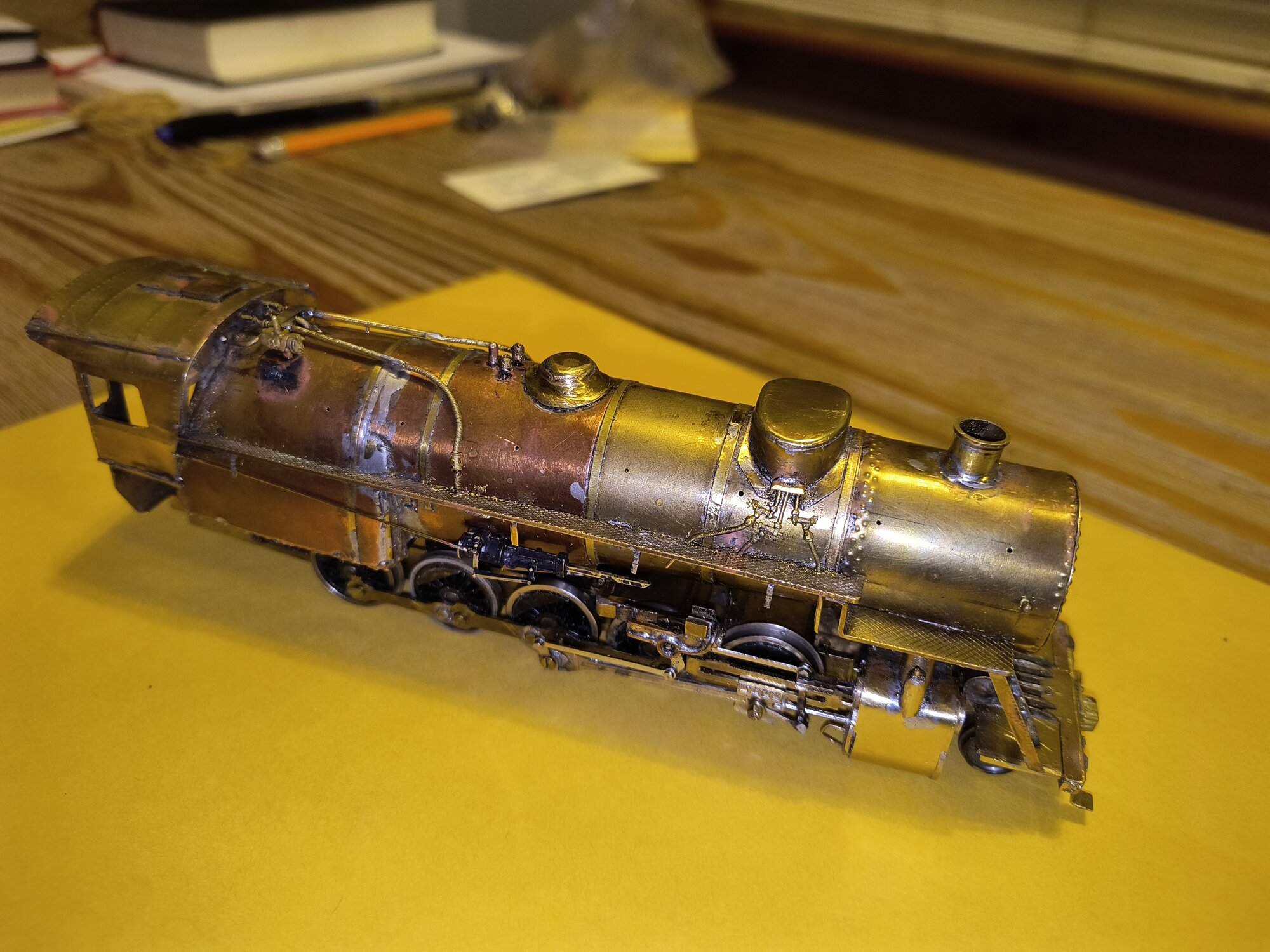

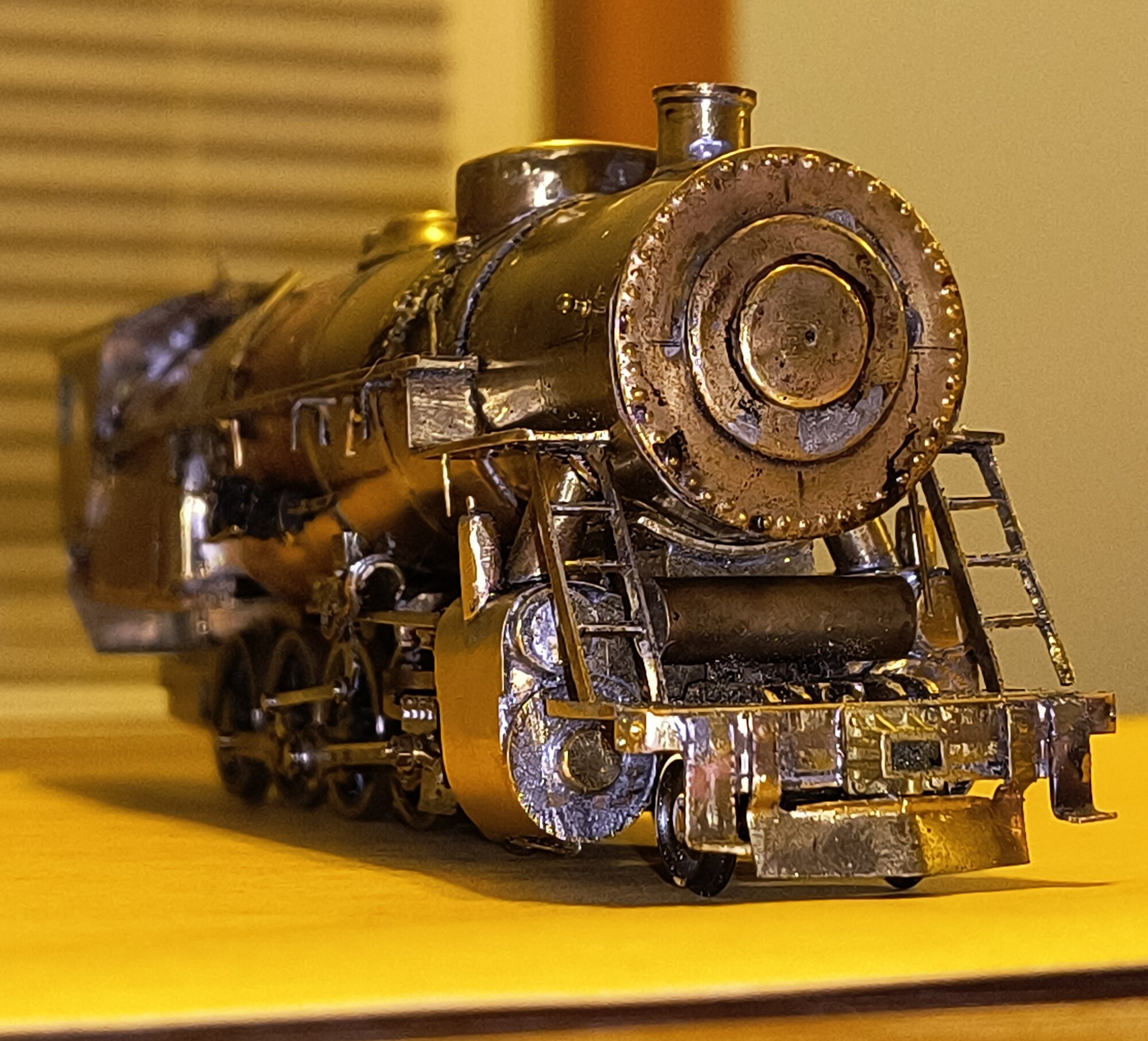

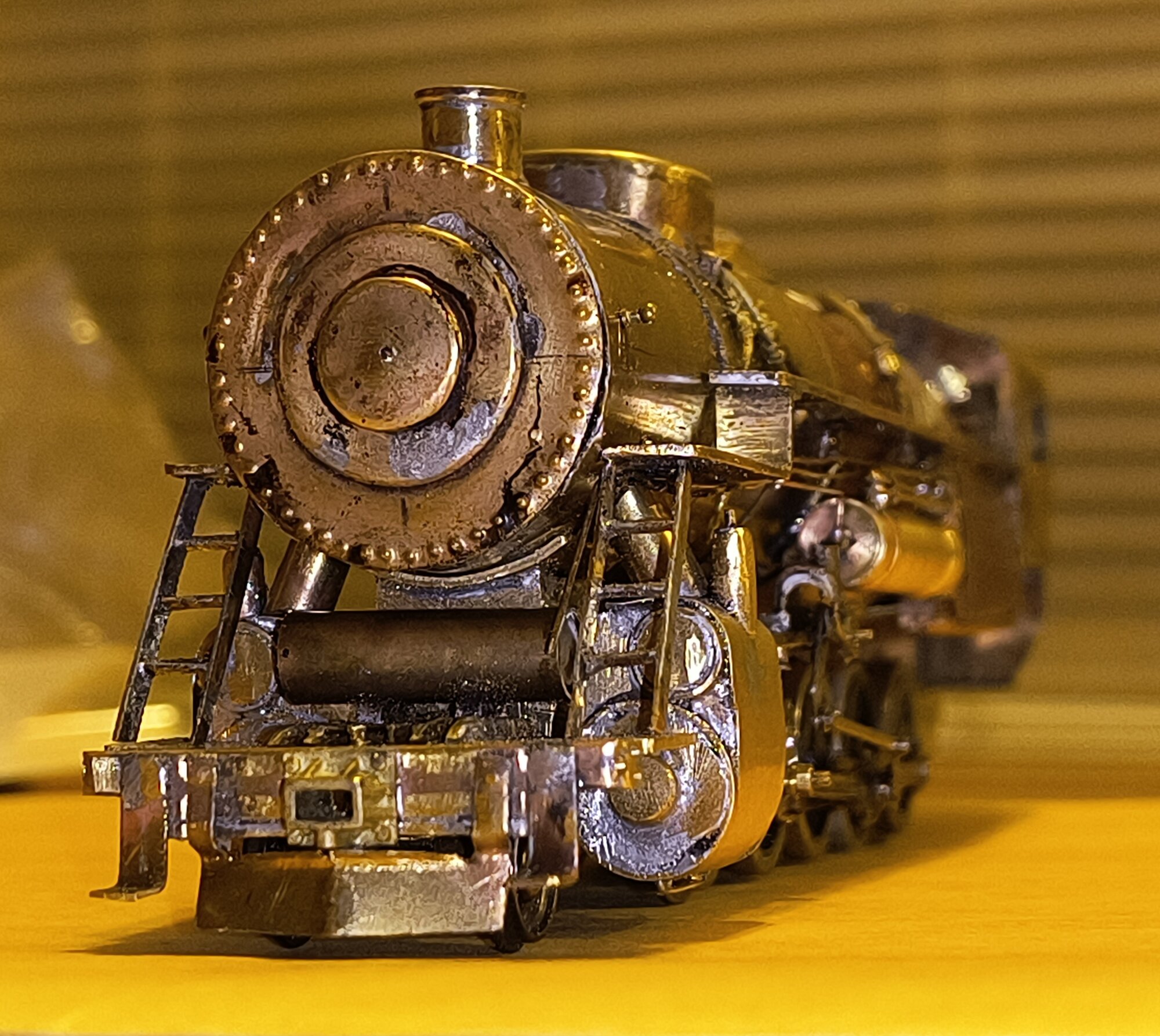

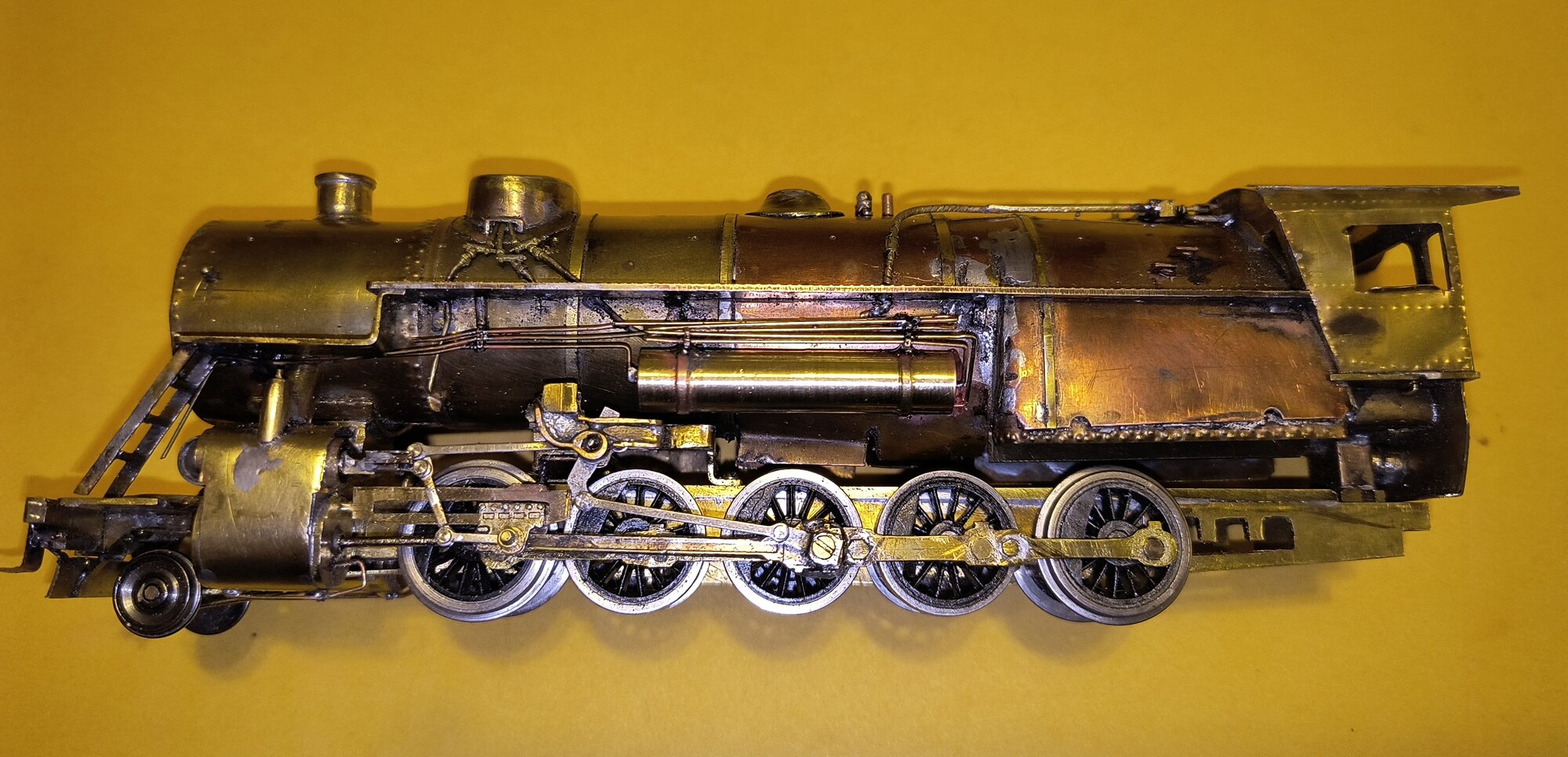

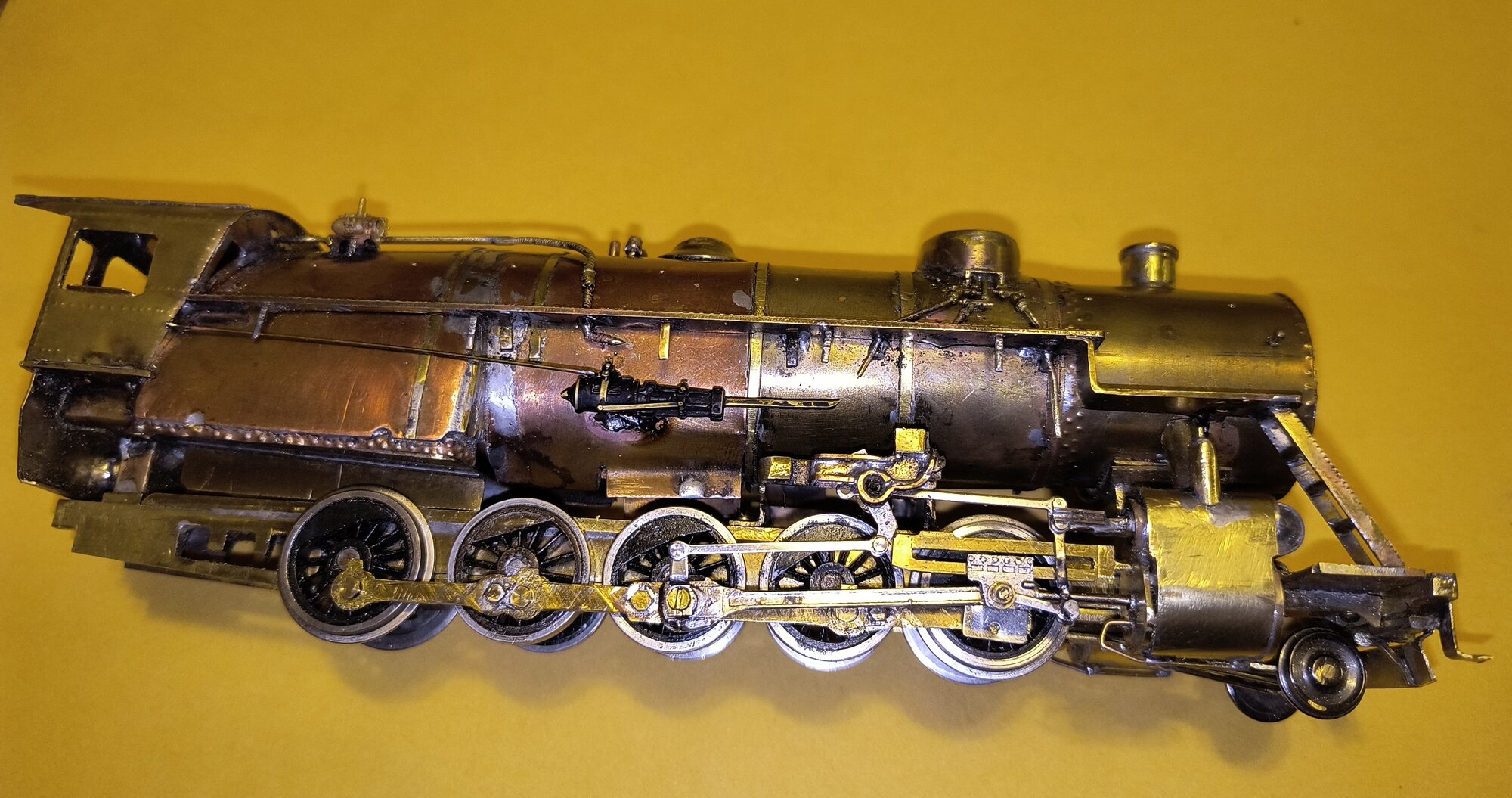

Today i was on L&NE F-1 all day detailing it.

On the firemans side did the main air tank with the piping, steps on the boiler near tha cab.

Top of the boiler; three safety valves (these had three as did most of the large steam), two thick pipes from the turret down to below the catwalk.

On the engineers side i put power reverse with the rod and turbo generator near the cab. All this doesn't seem like much, but i have no proper drawings for F-1 and even the Western Maryland version has different piping and there are errors in Western Maryland version drawings. There was a lot of eyeing the stuff before i was able to solder it in.

The main tank i shaped on my lathe and it came out a little too long, but being a solid brass rod and heavy, i decided to mount this one. I need all the weight i can get on this monster. Piping for that tank turned out to be especially hard, lots of bends in the brass rods and trying to hold everything together for soldering was challenging. I'm still figuring out all the piping as i go along just studying the pictures of real ones and some picks of brass models on internet. I'll have to purchase more 0.020 rods as i've ran out of that and will need it for airlines on the engineers side. I'm probably not even half way done with details on the locomotive. Still to do compressors with their piping and shields, piping under the catwalk on engineers side, injectors on both sides with their piping, detail on sandbox; handrails and hatches.

On the firemans side did the main air tank with the piping, steps on the boiler near tha cab.

Top of the boiler; three safety valves (these had three as did most of the large steam), two thick pipes from the turret down to below the catwalk.

On the engineers side i put power reverse with the rod and turbo generator near the cab. All this doesn't seem like much, but i have no proper drawings for F-1 and even the Western Maryland version has different piping and there are errors in Western Maryland version drawings. There was a lot of eyeing the stuff before i was able to solder it in.

The main tank i shaped on my lathe and it came out a little too long, but being a solid brass rod and heavy, i decided to mount this one. I need all the weight i can get on this monster. Piping for that tank turned out to be especially hard, lots of bends in the brass rods and trying to hold everything together for soldering was challenging. I'm still figuring out all the piping as i go along just studying the pictures of real ones and some picks of brass models on internet. I'll have to purchase more 0.020 rods as i've ran out of that and will need it for airlines on the engineers side. I'm probably not even half way done with details on the locomotive. Still to do compressors with their piping and shields, piping under the catwalk on engineers side, injectors on both sides with their piping, detail on sandbox; handrails and hatches.

Last edited: