goscrewyourselves

I'm the one

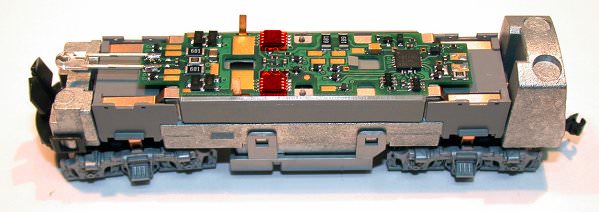

A week or so ago I inadvertently burnt out the TCS decoder on my F7 A. The decoder was replaced by TCS and this evening I was going to install it. Before doing so though, I checked the engine itself for operation by connecting wires from my NCE to the Motor Tabs on the engine. The only thing that happened, or I heard, was a "buzzing sound" from the motor.

I assumed that was a good thing so installed the decoder (brand new). Placed the engine on the track and nothing, naddah, no motor sound (buzzing) no movement, dead as a door nail.

I am assuming the decoder is okay as it is new; as such I am thinking there is something wrong with the engine itself. Could that be the problem and, if so, what might the problem be and is it repairable?

I don't know if it is me or this engine just doesn't like me as I have never had problems with any others.

I assumed that was a good thing so installed the decoder (brand new). Placed the engine on the track and nothing, naddah, no motor sound (buzzing) no movement, dead as a door nail.

I am assuming the decoder is okay as it is new; as such I am thinking there is something wrong with the engine itself. Could that be the problem and, if so, what might the problem be and is it repairable?

I don't know if it is me or this engine just doesn't like me as I have never had problems with any others.