You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Improving Our Steam Engines Performance

- Thread starter beiland

- Start date

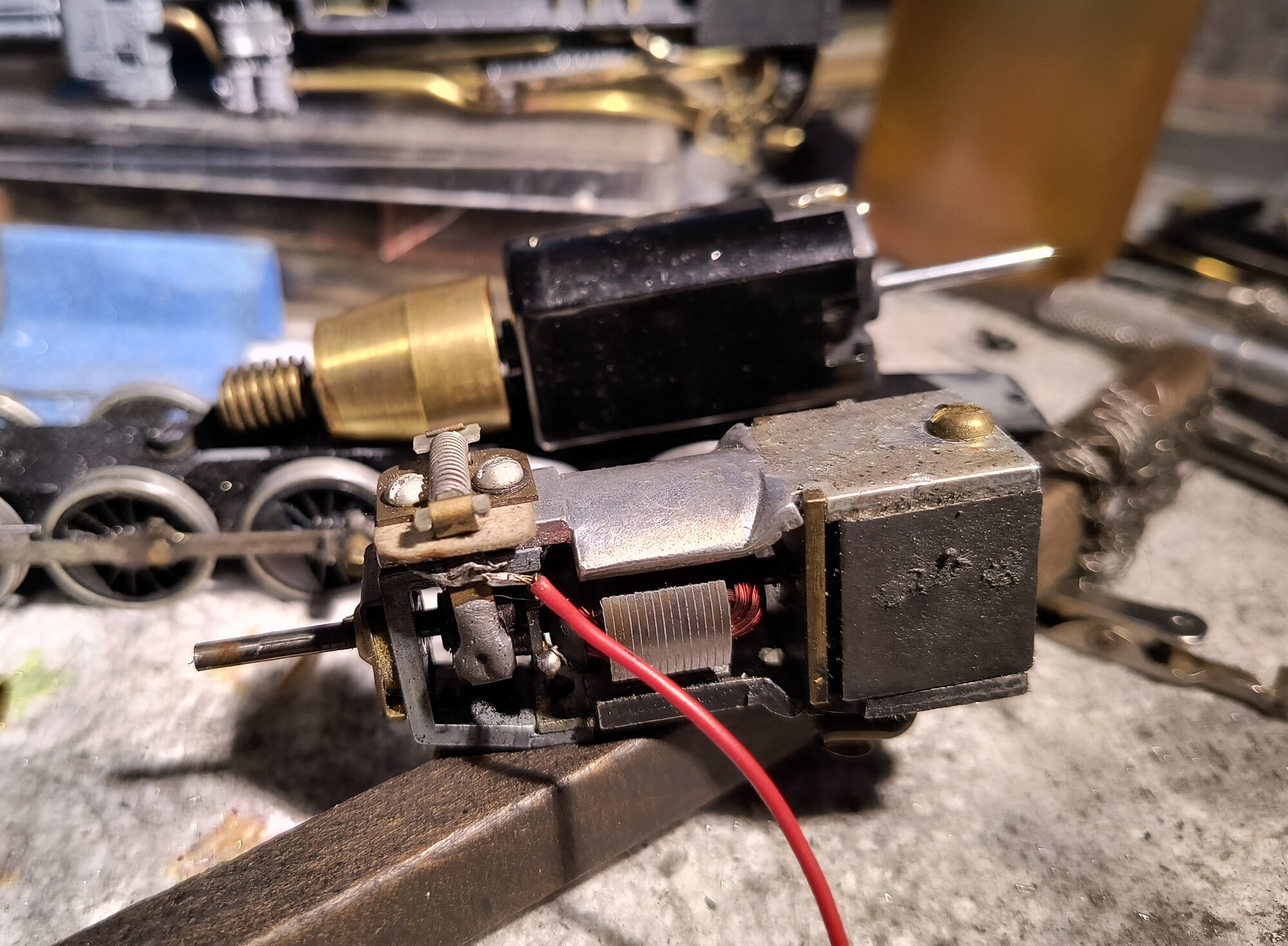

After my last post on this thread, I changed my Big Boy (late 60's version) to a dual motored machine. I had first regeared the tower gears to be 33% slower but the single cab mounted can motor would still overheat and I was sure it's life would be short. So finally, after a lot of research, I cut a piece out of the center zinc and mounted two motors, 1 in the cab and the second in the boiler area.

The first motors I installed did not pan out because they would run at very different speeds even though they were supposed to be identical. I messed around with a second decoder on the front tower but was not able to sinc the speeds to my liking. Next, I ripped those motors out and installed two motors from NWSL and the big steam Tsunami 2200....oh what a difference. This locomotive will pull 15+ cars up my 3.5-4% incline without hesitation.

If any of you want more information about this mod, I will be happy to share more details about my findings.

The first motors I installed did not pan out because they would run at very different speeds even though they were supposed to be identical. I messed around with a second decoder on the front tower but was not able to sinc the speeds to my liking. Next, I ripped those motors out and installed two motors from NWSL and the big steam Tsunami 2200....oh what a difference. This locomotive will pull 15+ cars up my 3.5-4% incline without hesitation.

If any of you want more information about this mod, I will be happy to share more details about my findings.

KriegslokBR52

Well-Known Member

What kind of motors did you install? NWSL number?After my last post on this thread, I changed my Big Boy (late 60's version) to a dual motored machine. I had first regeared the tower gears to be 33% slower but the single cab mounted can motor would still overheat and I was sure it's life would be short. So finally, after a lot of research, I cut a piece out of the center zinc and mounted two motors, 1 in the cab and the second in the boiler area.

The first motors I installed did not pan out because they would run at very different speeds even though they were supposed to be identical. I messed around with a second decoder on the front tower but was not able to sinc the speeds to my liking. Next, I ripped those motors out and installed two motors from NWSL and the big steam Tsunami 2200....oh what a difference. This locomotive will pull 15+ cars up my 3.5-4% incline without hesitation.

If any of you want more information about this mod, I will be happy to share more details about my findings.

The motors are 2025-D. This is a double shafted motor as the single shaft version was listed as out of stock. I cut the rear shaft of the cab mounted motor but left it on for boiler mounted one as there was enough room. The gearing is 317-6. These are a little tricky if you haven't regeared before.

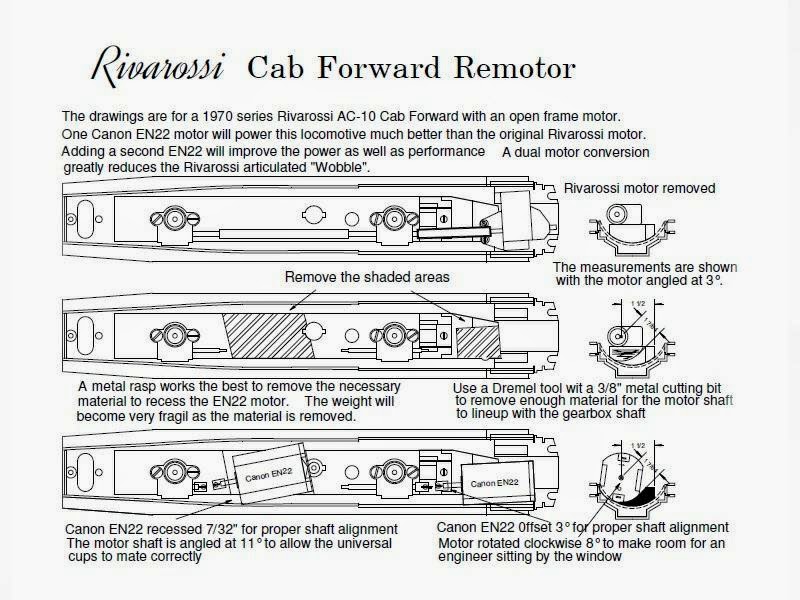

Found a discussion where i was playing with dual motors in Rivarossi engines,..

forum.mrhmag.com

forum.mrhmag.com

modelrailroadforums.com

modelrailroadforums.com

Rivarossi BigBoy & Challenger

This blog thread is to discuss AHM / Rivroassi articulateds and my experiences with them. I replaced the stock motors with some relatively cheap can motors. And in one case I hooked up two identical motors in one engine,...one for each set of drivers. The motors ran alike so it worked out fine...

Can motor for rivarossi 2-8-8-2

Hi there i was wondering if some one would tell me what the best can motor for a rivarossi 2-8-8-2 would be thinking of adding dcc to it Tia.

modelrailroadforums.com

modelrailroadforums.com

Dual Motor Installations

BTW if you get real ambitious you might look thru some examples of dual motor installations such as this,

http://melvineperry.blogspot.com/p/blog-page_15.html

BTW if you get real ambitious you might look thru some examples of dual motor installations such as this,

http://melvineperry.blogspot.com/p/blog-page_15.html

KriegslokBR52

Well-Known Member

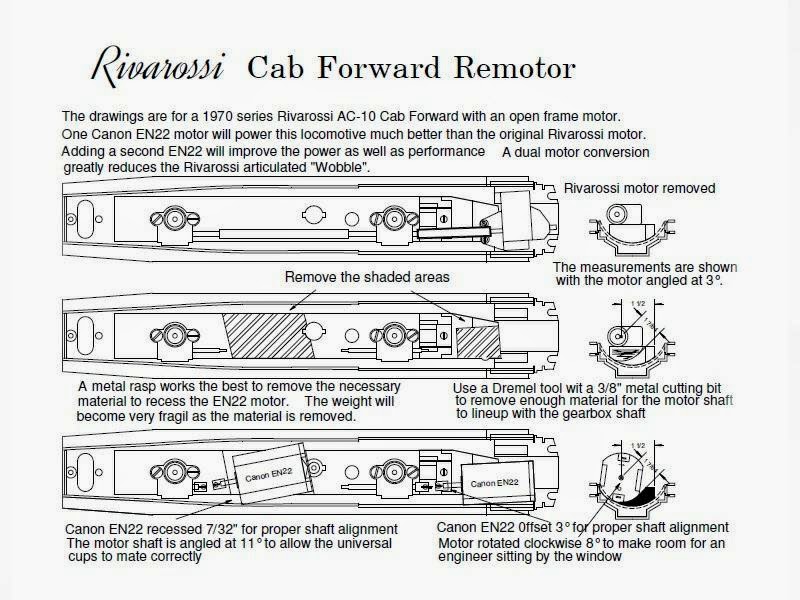

On my Penn Line 2-10-0 i have used a NWSL #18367-9 motor which i purchased probably 20 years ago especially for a large steam. Not sure where it fits power wise with other motors, but it seems pretty torquey and best of all it's slow running.

The image is as i was just fitting this thing on the main frame. The flywheel is from Blue Box Athearn diesel, after i ground it in a lathe and put the oryginal worm gear that was on that DC71 in the foreground. Being a double shaft motor i ground off the sticking out shaft in the rear. The motor/flywheel combination took just a little more space than DC71 and caused me to grind off the backhead wall of the boiler.

This is really a one off, since the boiler/cab is a lucky find made years ago by Cary to replace undersized Bowser boiler on the Pennsy "Hippo". There is a slight grinding noise as more power is added to speed up the loco and i hope to eliminate that with some more experimenting with how the worm gear is held against the main gear. Years ago there was an article in one of the popular magazines on how to repower Bowser 2-10-0, but i'm not following that recipe since i can't locate that article, and there are some mods i made to suit my own tastes.

The image is as i was just fitting this thing on the main frame. The flywheel is from Blue Box Athearn diesel, after i ground it in a lathe and put the oryginal worm gear that was on that DC71 in the foreground. Being a double shaft motor i ground off the sticking out shaft in the rear. The motor/flywheel combination took just a little more space than DC71 and caused me to grind off the backhead wall of the boiler.

This is really a one off, since the boiler/cab is a lucky find made years ago by Cary to replace undersized Bowser boiler on the Pennsy "Hippo". There is a slight grinding noise as more power is added to speed up the loco and i hope to eliminate that with some more experimenting with how the worm gear is held against the main gear. Years ago there was an article in one of the popular magazines on how to repower Bowser 2-10-0, but i'm not following that recipe since i can't locate that article, and there are some mods i made to suit my own tastes.

I think, way back when, that motor kit was called a Helix Humper.On my Penn Line 2-10-0 i have used a NWSL #18367-9 motor which i purchased probably 20 years ago especially for a large steam. Not sure where it fits power wise with other motors, but it seems pretty torquey and best of all it's slow running.View attachment 184061

The image is as i was just fitting this thing on the main frame. The flywheel is from Blue Box Athearn diesel, after i ground it in a lathe and put the oryginal worm gear that was on that DC71 in the foreground. Being a double shaft motor i ground off the sticking out shaft in the rear. The motor/flywheel combination took just a little more space than DC71 and caused me to grind off the backhead wall of the boiler. View attachment 184062

This is really a one off, since the boiler/cab is a lucky find made years ago by Cary to replace undersized Bowser boiler on the Pennsy "Hippo". There is a slight grinding noise as more power is added to speed up the loco and i hope to eliminate that with some more experimenting with how the worm gear is held against the main gear. Years ago there was an article in one of the popular magazines on how to repower Bowser 2-10-0, but i'm not following that recipe since i can't locate that article, and there are some mods i made to suit my own tastes.

Old 97

Hogger

I think, way back when, that motor kit was called a Helix Humper.

Actually, steam was replaced by diesel in the real world because of maintenance costs, not pulling power. Steam engine builders tended to understate their locomotives horsepower, where diesel builders tended to overstate theirs. It takes lots of reading but if you dig into books about the prototype, you'll find some interesting information on things like how many tons various locomotives were rated for in various districts of a particular railroad. The Santa Fe and the SP are the ones I'm most familiar with, and if you look through enough photos in enough books you can see some fairly large engines pulling some short trains! Double heading got very common as soon as grades got into the picture. Then we have the issue that physics doesn't scale, and our layout grades and curve radii are much more severe than the prototypes were. The GS-4 was rated at 5500 HP. You'd need four F units to equal that at that time. Most model steamers will pull pretty close to what one diesel will in my experience. After all no matter what the model is or looks like, we're still transmitting the power of a single can motor to the rails.Brian, you've discovered one of the two main reasons steam was replaced by diesel in the real world. A steam engine can only pull so much, and if you want more cars on that train, you'll need to add another steam engine (with crew). If you have diesels, you just keep adding engines (within reason) until they can pull the train. With one crew.

I remember a Model Railroader article from years ago, detailing how to convert a baggage car or boxcar into a helper engine. Don't ask how many years ago that's been, but it's been at least a decade.

We can add weight. We can make sure the weight is centered over the drivers which is actually more important. You need to make sure that any lead or trailing trucks aren't too heavily sprung such that they take weight off the drivers. I always liked Bullfrog Snot. It's quite effective. I was able to get a Westside GS-3 to pull a 16 car Daylight train around our club's layout which has 48" minimum radius and a 2% ruling grade by applying it to the insulated side of the center two driving axles. On a flat layout it was able to do it out of the box. A combination of grade and radius is the worst condition we face. The radius compounds the effect of the grade, so if you have a smallish layout with 22" maximum radius and 3-4% grades, yep, you'll have trouble with a single steamer and a long train! On the other hand, the below video is if one of my brass 2-8-2's with a 22 car train. 23 actually because you have to count the tender. This train made it around the club layout with no issues. It has been re-motored, but that's all.

Perhaps revisit a few of my earlier postings in this subject thread. I was/am sutlly impressed with these these Roco steamers

https://modelrailroadforums.com/for...-engines-performance.34036/page-3#post-518431

Some of the photos I posted in this discussion do NOT show up, so perhaps see identical discussions WITH PHOTOS here,..

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?trail=125

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?pid=1331442808

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?trail=100

I found this particular posting interesting,..

https://modelrailroadforums.com/for...-engines-performance.34036/page-3#post-518431

Some of the photos I posted in this discussion do NOT show up, so perhaps see identical discussions WITH PHOTOS here,..

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?trail=125

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?pid=1331442808

https://forum.mrhmag.com/post/improving-our-steam-engines-performance-12219656?trail=100

I found this particular posting interesting,..

Tender Drive for Steam, thinking out loud

just found this older discussion

Tender Drive for Steam, thinking out loud https://forum.mrhmag.com/post/tender-drive-for-steam-thinking-out-loud-12190154

Option 1 - Motor in the tender, powered locomotive

Option 2 - Powered tender, free rolling engine

Quote:

short excerpt..

Some people dislike the design simply because they feel that the model should be powered like the prototype, with the drivers doing the pulling. I doubt those same people have a problem with a model E8 with all six axles powered, however. The objective is to build a functional model which runs reliably, pulls a prototypical load, and disguises as much as possible the fact that it is not a steam powered locomotive. An electric motor driving the tender wheels seems no less prototypical than an electric motor driving spoked wheels underneath a lead weight, in my opinion.

The other complaint I have heard is that some people like to see the drivers slipping pulling a heavy grade or starting a train. While prototypical, I feel that slipping the drivers should be avoided on a model. It wears out the drivers and doesn't really achieve anything useful. It reminds me of those videos showing guys burning the tires off their cars and motorcycles - testosterone fueled silliness.

Last edited:

In our hobby, traction and power are two big factors. Diesel locomotives tend to get better traction with much smaller wheels and similar weight. We might ask why but we need to look at the physics involved where the motors power is applied to the driving wheels. With a diesel locomotive , power is applied to all driving wheels to gears located on the driving axles near the center of rotation developing a very efficient transfer of power. With our steam models, the power is transferred to only one axle (2 with articulated) and then extend to the other wheels with rods pivoting close to the outer diameter of the wheels creating a pulsing surge of power and promoting traction loss.

Weight and traction tires or bullfrog snot really help to promote better performance but the fact remains that this is a very inefficient method of transfer of power.

Prototypical steam locomotives were a constant maintenance headache and to a lesser degree, model steam locomotives require more maintenance than their diesel counterparts.

So why do I model mostly steam? I just loving watching those drivers work!

Weight and traction tires or bullfrog snot really help to promote better performance but the fact remains that this is a very inefficient method of transfer of power.

Prototypical steam locomotives were a constant maintenance headache and to a lesser degree, model steam locomotives require more maintenance than their diesel counterparts.

So why do I model mostly steam? I just loving watching those drivers work!

You just can’t get enough weight into those Bachmann steamers to get them to pull anything. whatever alloy they use ismjust too darn light. I had the same issue with a Bachman Spectrum GS-4. It wouldnt pull much at all. I finally sold it I have some PFM brass Santa Fe northerns that are pretty good pullers though. The 2-10-2 and the 2-10-4’s are no slouch either.I got the new traction tires for that latest Roco steamer I bought. I had measured the wheels as 10.7 mm diameter, and the best estimate of the size I should use was their 9mm ones. It turns they were correct for a tight fit. I surely don't think I would have liked to try and fit the 6mm ones that another seller suggested.

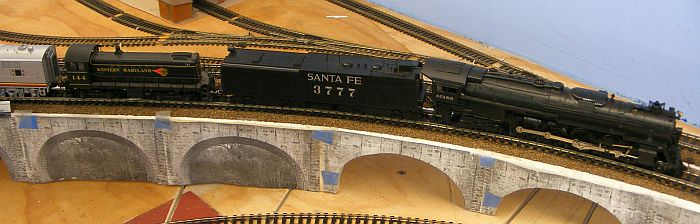

The engine runs like a champ,..pulls 15 cars up my rather steep grades, ...both of them. Turns out my steeper grade is not the most difficult of the two, ….due to its shorter length not involving all 15 cars at one time. The longer, less-steep grade is more difficult as then the engine is then trying to pull the entire length of 15 cars up a grade. Here are a few photos of the train on both grades.

first 2 photos of train going down the steeper grade

View attachment 137434

View attachment 137435

Then this one with train coming up the longer less steep grade (still steep at approx 3.5)

View attachment 137436

This is the loco,

View attachment 137437

...and this is Bachmann Northern that appears to have enough power, BUT not enough weight to do the job (look at all the weight taped to the top). I seriously doubt if I could find room in that boiler for all that weight (and that still was NOT enough weight to give it the traction to pull that 15 car train....wow).

View attachment 137438

Another good reason for a pusher/helper car,...and/or a re-evaluation of model steam loco 'driver' design.

All true. Even with steamers the smaller drivered engines had better tractive effort where large drivered locos got slippery, and all axles geared is more efficient than a single geared axle with rods transmitting power to the rest. I don’t have pulsing power issues though. None of my engines lope when running or have any sort of “hitch in their git-a-long“. That’s a driver quartering issue, another thing diesels don’t have to worry about.In our hobby, traction and power are two big factors. Diesel locomotives tend to get better traction with much smaller wheels and similar weight. We might ask why but we need to look at the physics involved where the motors power is applied to the driving wheels. With a diesel locomotive , power is applied to all driving wheels to gears located on the driving axles near the center of rotation developing a very efficient transfer of power. With our steam models, the power is transferred to only one axle (2 with articulated) and then extend to the other wheels with rods pivoting close to the outer diameter of the wheels creating a pulsing surge of power and promoting traction loss.

Weight and traction tires or bullfrog snot really help to promote better performance but the fact remains that this is a very inefficient method of transfer of power.

Prototypical steam locomotives were a constant maintenance headache and to a lesser degree, model steam locomotives require more maintenance than their diesel counterparts.

So why do I model mostly steam? I just loving watching those drivers work!

trailrider

Well-Known Member

Is that why my "hacksaw conversion" Mantua 2-10-4, even though the locomotive weighs just under two pounds, will just about handle six 1.2 oz hopper cars plus its tender and a waycar (caboose to non-C.B.&Q fans), up Pi Hill (that's a 3.24% grade with 20" radius curves at top and bottom? A pair of Athearn bluebox F-7 A-B motors will handle at least 8 of the hoppers. Don't know how much would handled by the steamer on the level as I don't have more than 4 feet level straight length on my layout.All true. Even with steamers the smaller drivered engines had better tractive effort where large drivered locos got slippery, and all axles geared is more efficient than a single geared axle with rods transmitting power to the rest. I don’t have pulsing power issues though. None of my engines lope when running or have any sort of “hitch in their git-a-long“. That’s a driver quartering issue, another thing diesels don’t have to worry about.

Old 97

Hogger

22 cars in all!!!! Impressive. Steamer was pretty quiet too.

All true. Even with steamers the smaller drivered engines had better tractive effort where large drivered locos got slippery, and all axles geared is more efficient than a single geared axle with rods transmitting power to the rest. I don’t have pulsing power issues though. None of my engines lope when running or have any sort of “hitch in their git-a-long“. That’s a driver quartering issue, another thing diesels don’t have to worry about.

By using the description surging, I was not indicating that there is noticeable loping etc. It’s just the nature of power being applied further from the rotating axis.All true. Even with steamers the smaller drivered engines had better tractive effort where large drivered locos got slippery, and all axles geared is more efficient than a single geared axle with rods transmitting power to the rest. I don’t have pulsing power issues though. None of my engines lope when running or have any sort of “hitch in their git-a-long“. That’s a driver quartering issue, another thing diesels don’t have to worry about.

I understand what you are saying about Bachmann steamers. I own two and neither are very good pullers. One of them, a 4-8-4 has been a work in progress to keep it from derailing. I won’t put a decoder in it until it is a dependable runner.

I understand what you are saying about Bachmann steamers. I own two and neither are very good pullers. One of them, a 4-8-4 has been a work in progress to keep it from derailing. I won’t put a decoder in it until it is a dependable runner.

My older posting about the Bachmann 4-8-4

Pusher/Helper

Back to the pusher/helper idea.

I had been using that DL109 behind the steamers, and very successfully.

What smaller engine could I be using?

I happen to have a pretty heavy little switcher engine in my inventory,...an Alco S2 by Atlas,...but could this really substitute for the DL109.

WOW, it did a great job. First I put it behind that Bachmann Northern,..

Then behind one of my Mehano mountains,..just plain DC

I was really pleasantly surprised. This little Alco diesel model did a great job. I was pulling 20 car trains up the more difficult ramp side of my viaduct,....4.5% grade. It turns out to have a diecast frame that gives it superb weight.

I went onward to try this little diesel by itself. It couldn't quite make it, but it came close.

I then decided to get one of my Bachmann mountains out for a try. A slight problem arose here due to the Bachmann having a DCC decoder installed, so matching the speeds with the pure DC S2 needed a bit more attention. But it also worked extremely well. (BTW I tried the Bachmann mountain by itself, and was pleasantly surprised at its performance. Double heading these Bachmann mountains will definitely be on my list).

I'm convinced that a likely solution for pushing a lot of my steam engines is disguise one of these Atlas switchers into a aux water tender. Sure would save LOTS of custom efforts at adding extra weights to that variety of steamers.