railflyermodel

Member

Guys,

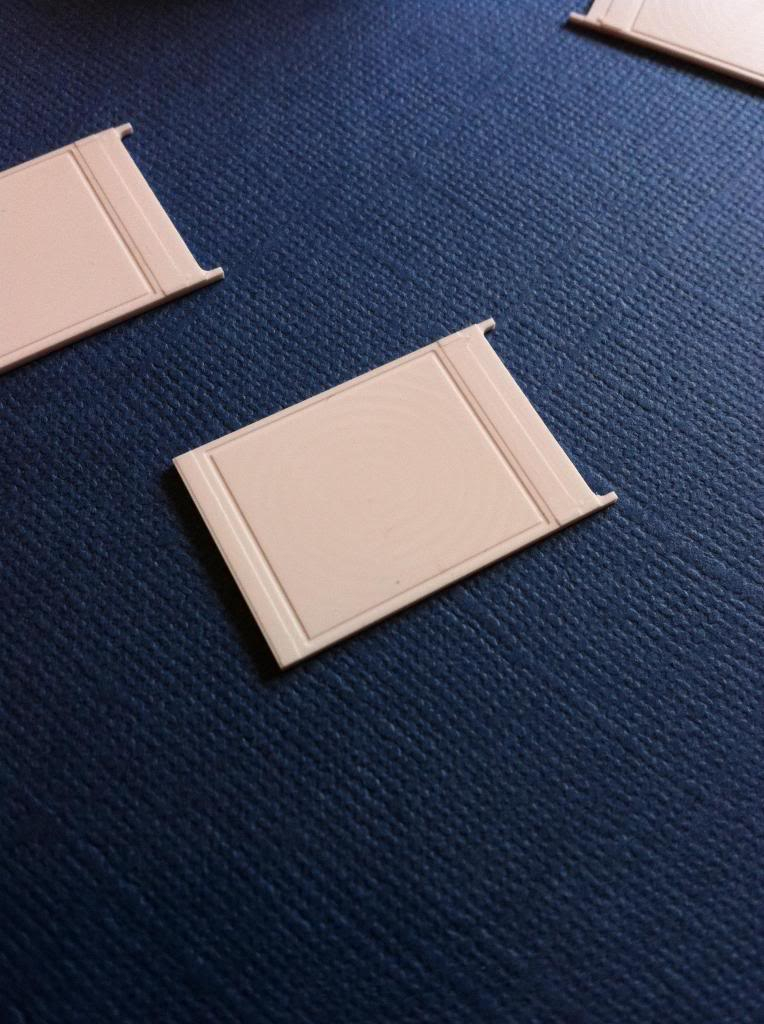

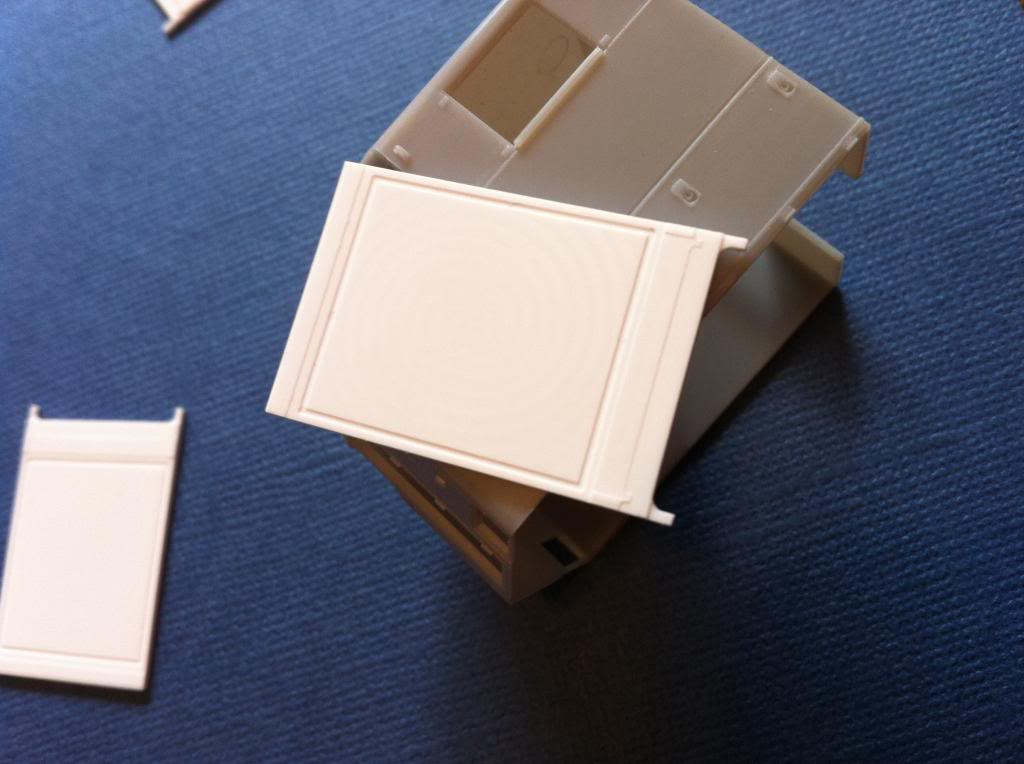

A new project we've got in production are hood sides for EMD/GMDD locomotives.

Here are test samples for the SD38/40/45-2 Clean Air Room roof.

This is a 3D milled styrene project. The roof section will have the correct radius, drilled holes, and all plate detail, features including flag holders will be machined into the sides.

The kits are cored to accept either Cannon or Railflyer hood doors and components.

They will be ready to start delivery this weekend. I am doing the production on our Datron M7HP. In the near future new frames, fuel tanks, and decks will appear. The decks will also be 3D milled styrene.

Links to the kits:

http://www.railflyermodel.com/collections/detail-parts-hood/gp38-2

http://www.railflyermodel.com/collections/detail-parts-hood/gp39-2

http://www.railflyermodel.com/collections/detail-parts-hood/gp40-2

http://www.railflyermodel.com/collections/detail-parts-hood/sd38-2

http://www.railflyermodel.com/collections/detail-parts-hood/sd40-2

All the best,

Christopher Howard, Railflyer Model Prototypes Inc.

www.railflyermodel.com

A new project we've got in production are hood sides for EMD/GMDD locomotives.

Here are test samples for the SD38/40/45-2 Clean Air Room roof.

This is a 3D milled styrene project. The roof section will have the correct radius, drilled holes, and all plate detail, features including flag holders will be machined into the sides.

The kits are cored to accept either Cannon or Railflyer hood doors and components.

They will be ready to start delivery this weekend. I am doing the production on our Datron M7HP. In the near future new frames, fuel tanks, and decks will appear. The decks will also be 3D milled styrene.

Links to the kits:

http://www.railflyermodel.com/collections/detail-parts-hood/gp38-2

http://www.railflyermodel.com/collections/detail-parts-hood/gp39-2

http://www.railflyermodel.com/collections/detail-parts-hood/gp40-2

http://www.railflyermodel.com/collections/detail-parts-hood/sd38-2

http://www.railflyermodel.com/collections/detail-parts-hood/sd40-2

All the best,

Christopher Howard, Railflyer Model Prototypes Inc.

www.railflyermodel.com

Last edited by a moderator: