railBuilderDhd

Active Member

Jeff,

First, let me say I'm not bothered at all with the post. In fact, I'm happy to see this. Your bride is much like one I'm designing now in my head and figuring out how to support the bride as well. I would love to see how you did the support with the music wire. Why did you use the music wire and not just the support of the I-beams that could be the support.

Feel free to start a different post or carry on here.

Dave

First, let me say I'm not bothered at all with the post. In fact, I'm happy to see this. Your bride is much like one I'm designing now in my head and figuring out how to support the bride as well. I would love to see how you did the support with the music wire. Why did you use the music wire and not just the support of the I-beams that could be the support.

Feel free to start a different post or carry on here.

Dave

I think thin metal alone would be less sturdy than the combination of foam on plywood. Unless the metal was fairly thick, it seems to me it would flex a lot, whereas the foam/plywood construction is solid and stiff. I suppose something like 1/8-inch aluminum sheet could work if properly supported, but the hassles of shaping it and drilling it would discourage me from trying it.

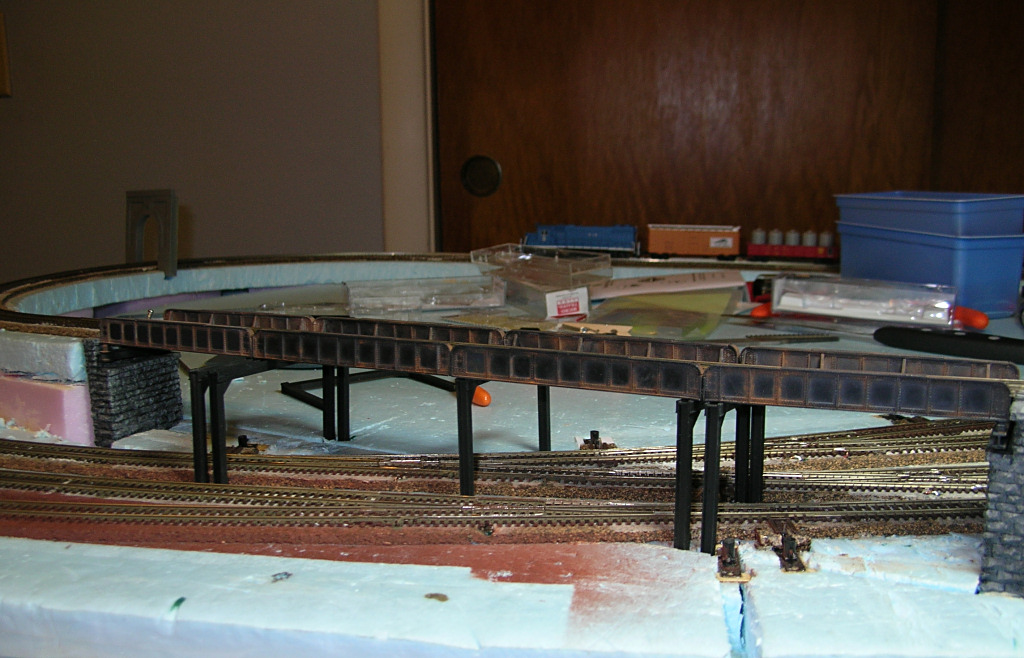

It just so happens that I have a long bridge over some tracks on a different part of my layout:

Here is later, more finished view:

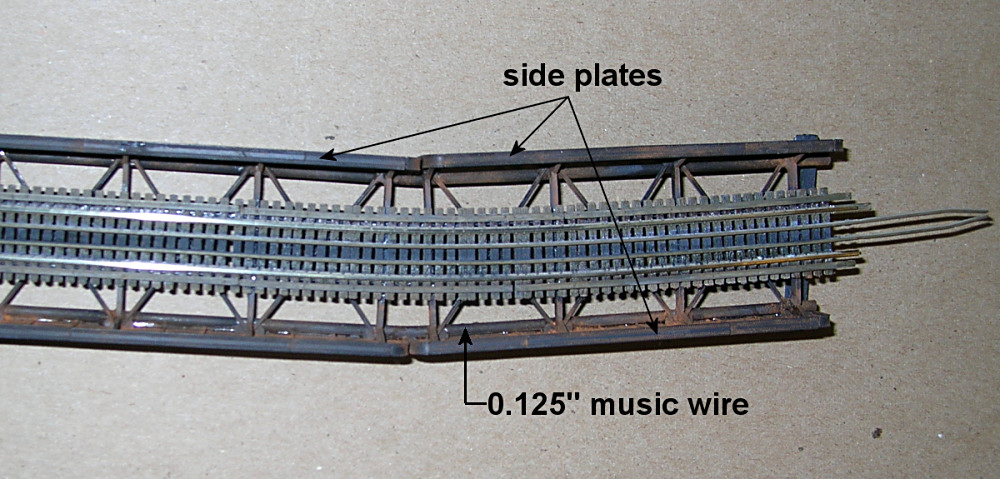

Although it's not real obvious from the photos, this bridge is gently curved. I kitbashed it from Walthers through plate girder kits. The I-beam supports that appear to be holding up the bridge are for cosmetic purposes only. I built 1/8-inch steel music wire into the structure of the bridge which makes it totally self-supporting. The I-beams are just for realism, although I'm not sure how prototypical they are! Somewhere there is a prototype for everything, right?

- Jeff

P.S. - I apologize to Dave (railBuilderDhd), the original poster for this thread, if I have contributed to taking his thread off-topic.