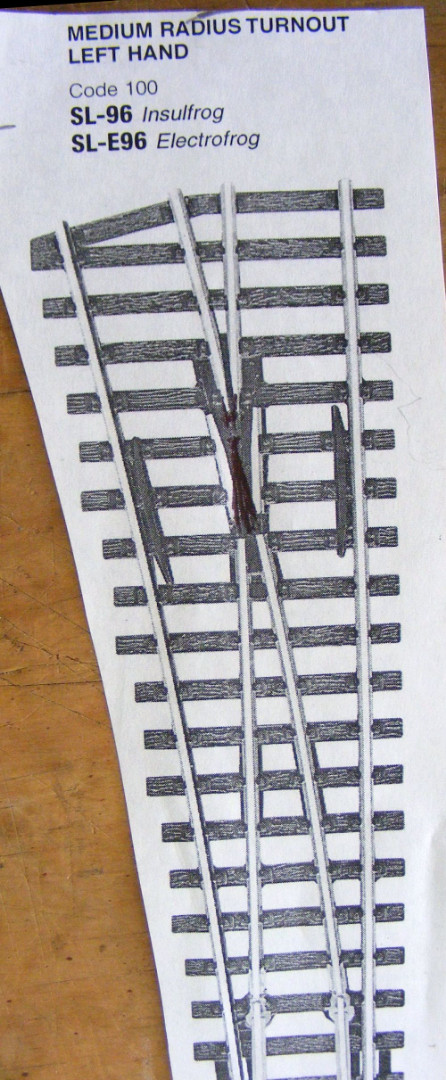

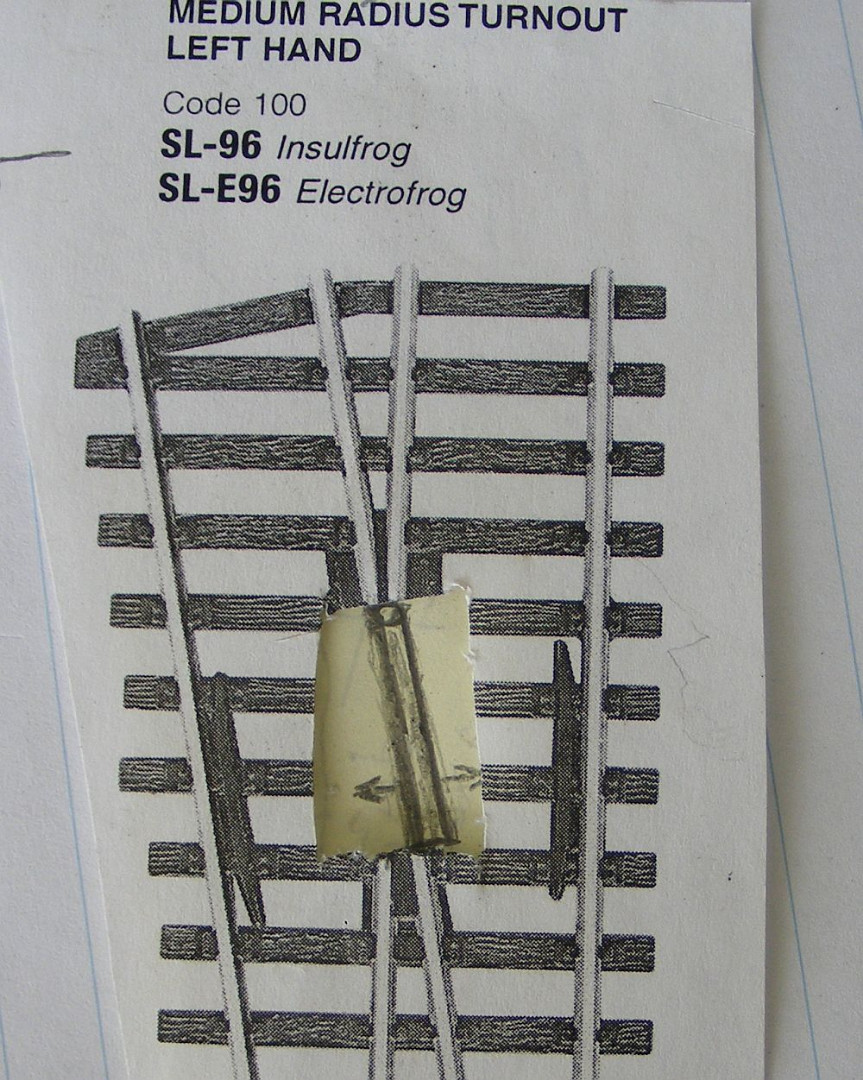

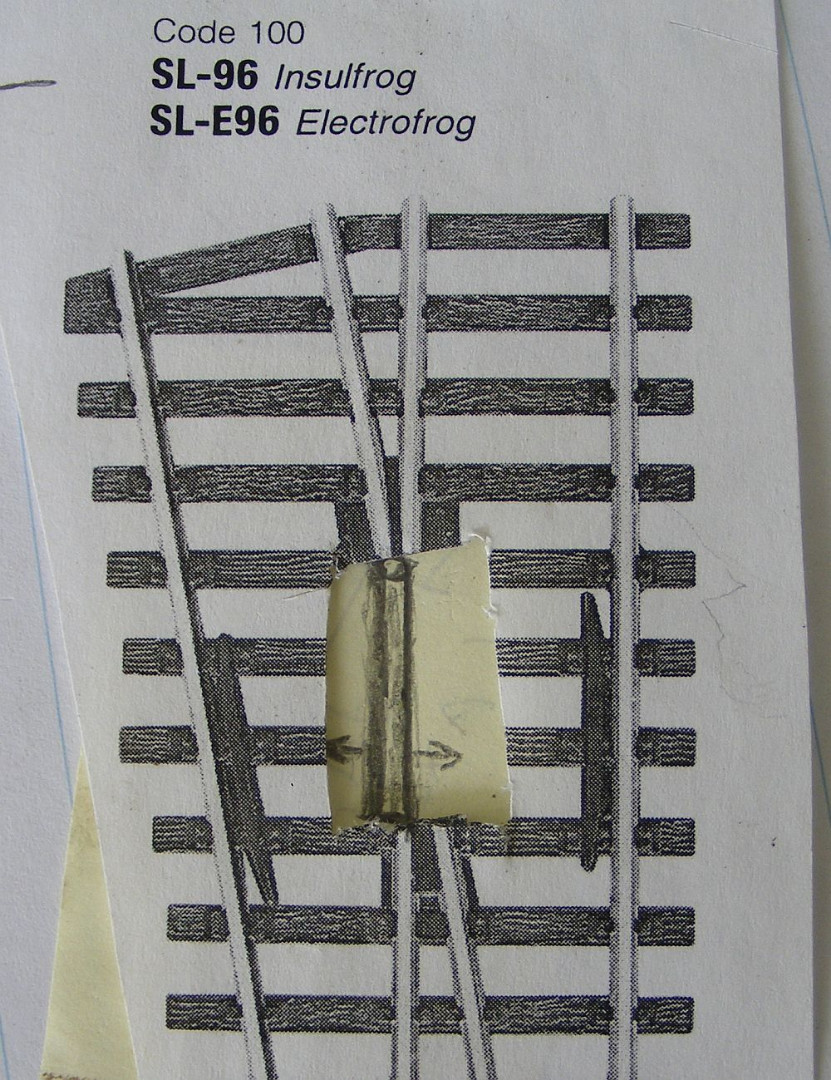

I've been working on a section of my track that contains some closely spaced curved turnouts (I refer to them as dbl-curves). The frog areas of these turnouts are pretty 'open spaces' that I have had some luck adding some plastic shims to in an effort to reduce some of this big wheel dipping,...that can lead to derailing of certain engines.

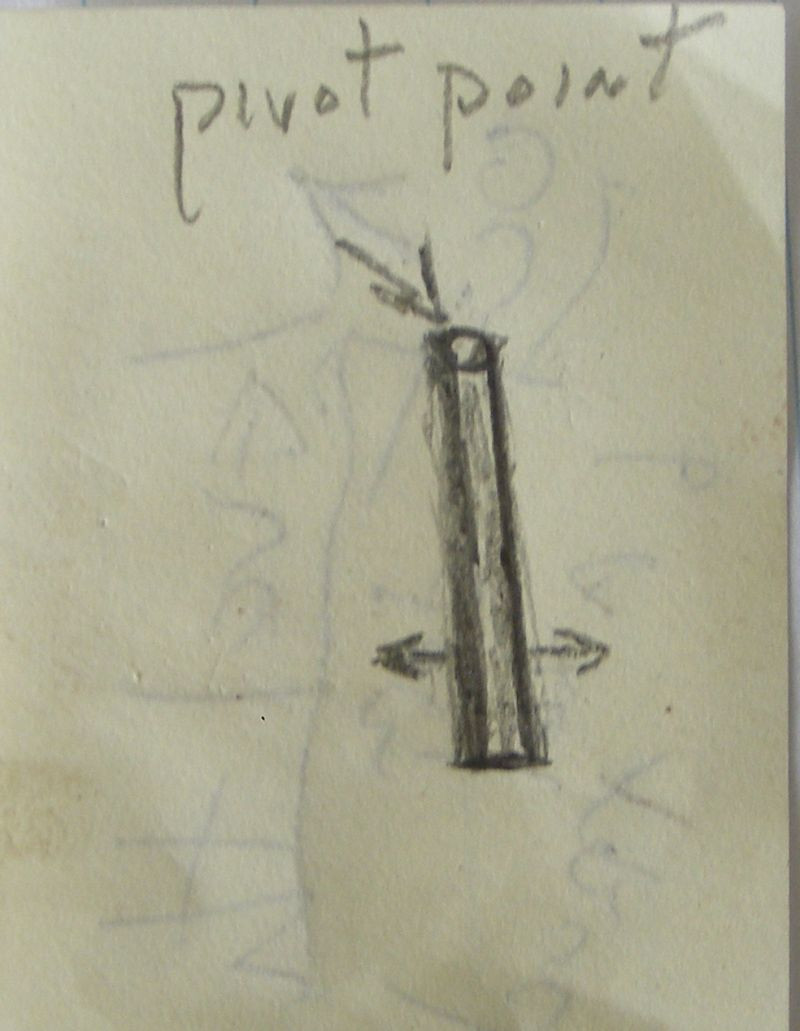

Got me to thinking what design improvements could be made to improve the situation?

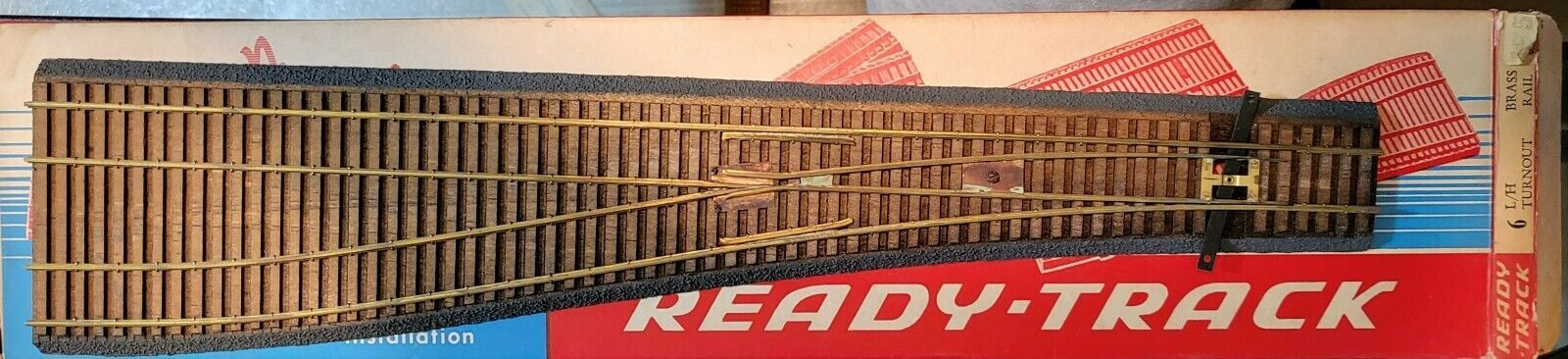

I seem to recall some much older American Flyer or Lionel turnouts that tried addressing the problem??

Got me to thinking what design improvements could be made to improve the situation?

I seem to recall some much older American Flyer or Lionel turnouts that tried addressing the problem??

![[720-Remote-Switches] [720-Remote-Switches]](/forum/proxy.php?image=https%3A%2F%2Fwww.thegilbertgallery.org%2FInfrastructure%2520Gallery%2Finfrastructure_track_files%2F720-Remote-Switches.jpg&hash=a12e3035b7e4d9cdb0a0041366824286)

![[26770-Manual-Switches-front] [26770-Manual-Switches-front]](/forum/proxy.php?image=https%3A%2F%2Fwww.thegilbertgallery.org%2FInfrastructure%2520Gallery%2Finfrastructure_track_files%2F26770-Manual-Switches-front.jpg&hash=77937281e8dc1d627a36326c500aba18)

![[dsc03847ymkkq] [dsc03847ymkkq]](/forum/proxy.php?image=https%3A%2F%2Fabload.de%2Fimg%2Fdsc03847ymkkq.jpg&hash=78d58c884cf4644519f8964b5991e871)

![[dsc03846hckw3] [dsc03846hckw3]](/forum/proxy.php?image=https%3A%2F%2Fabload.de%2Fimg%2Fdsc03846hckw3.jpg&hash=a40933e25aaf6f484a71369885ed31b2)

![[420px-Krustenis_ar_kustigu_serdi_1-18] [420px-Krustenis_ar_kustigu_serdi_1-18]](/forum/proxy.php?image=https%3A%2F%2Fupload.wikimedia.org%2Fwikipedia%2Fcommons%2Fthumb%2F5%2F55%2FKrustenis_ar_kustigu_serdi_1-18.jpg%2F420px-Krustenis_ar_kustigu_serdi_1-18.jpg&hash=0d92123fc2b4d4d14bae10d98fbe16bc)