bklynman01

Active Member

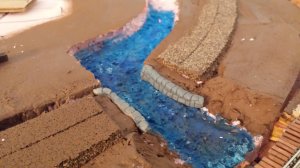

So I have a small bridge that carries a track that leads up to a coal mine. Originally, I wanted to hand lay this entire line and really put the time and effort into it, but decided that my skill level at this point is not quite where I would want it to be. Not that I couldn't do it, but I would always want something better here. So I decided to just use flex track and focus on other smaller items that wouldn't take as long. This one being the retaining wall on either side of the creek that runs through town.

I went to Michaels and purchased a block of modeling clay. It was under $10, and a whole lot of stuff can be made with it, including casts. In fact, the reason I even picked it up was to be able to make casts of brick walls in the future.

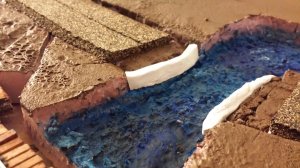

I cut a very small piece off and made the rough shape in place.

Then I removed the pieces, took them to my bench and "carved" in some brick faces. I used a small flat head screwdriver to press in the grooves and my fingers to smooth out the faces after. It took a little bit of work to get exactly what I wanted out of it. Once I was happy with the shape, I pressed it back into place to check the fit.

Then I placed my runners down on the soft clay to make the impression for where they will sit after final assembly.

I went to Michaels and purchased a block of modeling clay. It was under $10, and a whole lot of stuff can be made with it, including casts. In fact, the reason I even picked it up was to be able to make casts of brick walls in the future.

I cut a very small piece off and made the rough shape in place.

Then I removed the pieces, took them to my bench and "carved" in some brick faces. I used a small flat head screwdriver to press in the grooves and my fingers to smooth out the faces after. It took a little bit of work to get exactly what I wanted out of it. Once I was happy with the shape, I pressed it back into place to check the fit.

Then I placed my runners down on the soft clay to make the impression for where they will sit after final assembly.