I've completed the main deck benchwork for my new layout.

This is a "permenent" under benchwork (L-girder + beams attached to wall) as well as 8 removable sections of 2" foam framed in 1x3's. Each section is removable to work on in my shop or for possible moving, but not intended as a truely "modular" setup.

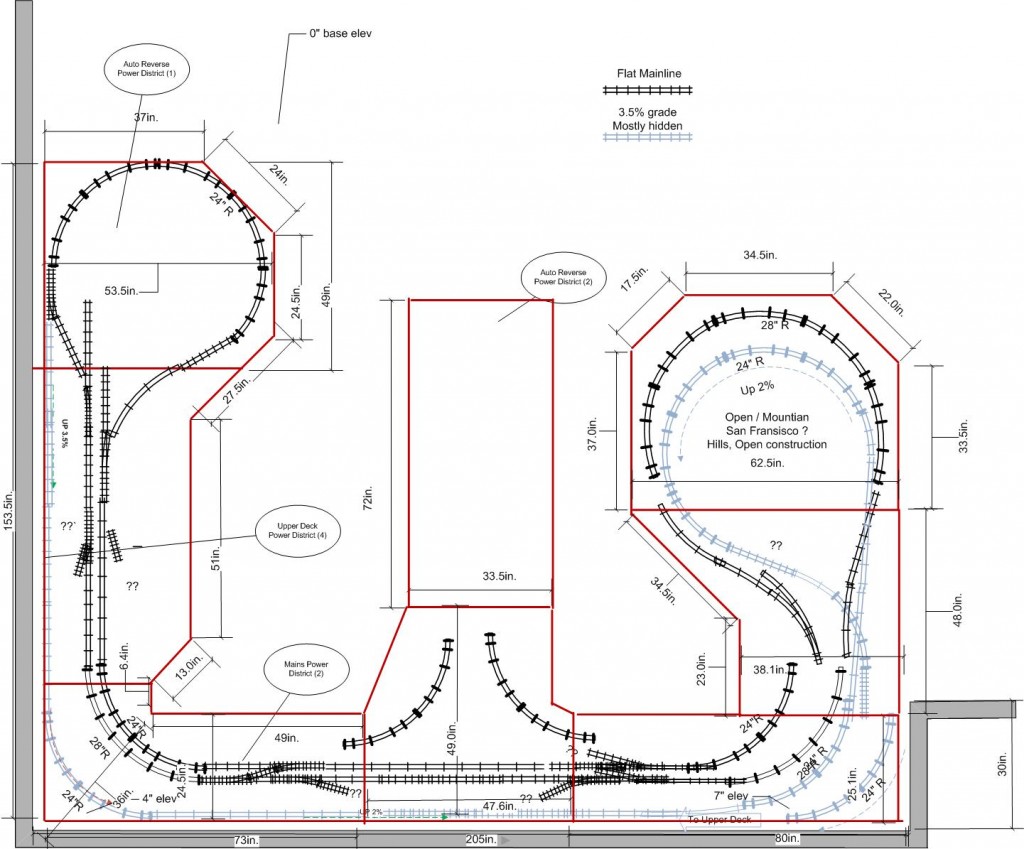

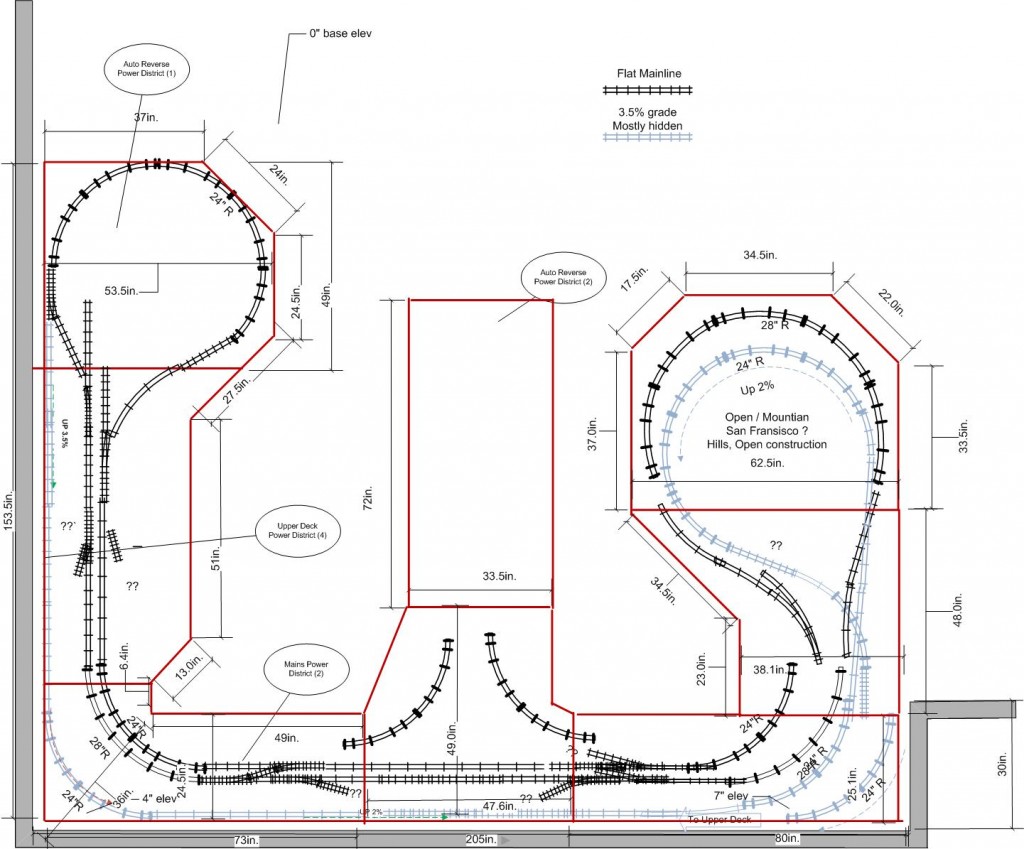

Track layout plan is not complete, just a rough draft, includes a nolix to an upper shelf deck at about 17" above the main deck.

Attached are the layout and a few views of the benchwork.

Now for better layout details (working on design in 1:1 scale using cardboard cutouts) and actual track laying ! (expect 100% hand laid including switches).

http://trains.calldei.com

-David

This is a "permenent" under benchwork (L-girder + beams attached to wall) as well as 8 removable sections of 2" foam framed in 1x3's. Each section is removable to work on in my shop or for possible moving, but not intended as a truely "modular" setup.

Track layout plan is not complete, just a rough draft, includes a nolix to an upper shelf deck at about 17" above the main deck.

Attached are the layout and a few views of the benchwork.

Now for better layout details (working on design in 1:1 scale using cardboard cutouts) and actual track laying ! (expect 100% hand laid including switches).

http://trains.calldei.com

-David