CaptSuperCow

Member

I have a large apartment, but as it is an apartment, I'm likely not to stay here for more than a few years. I've been mulling over layout design for quite a long time now and am finally working towards a solution.

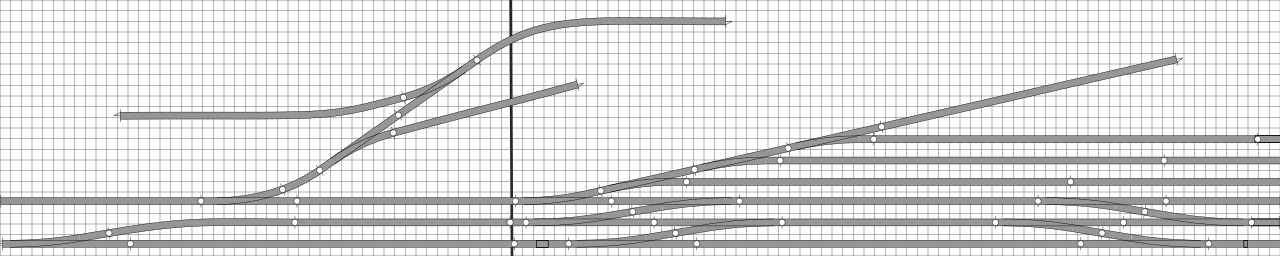

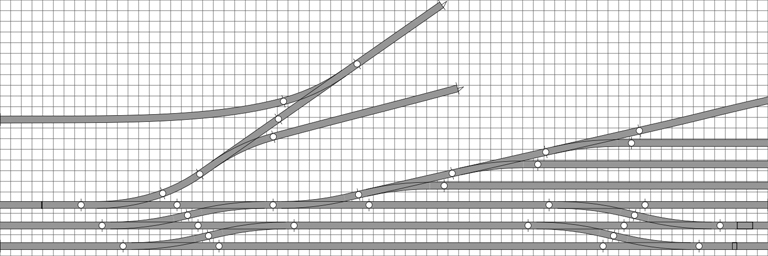

This plan is my first stab at the 2x6ft layout:

I plan to make this layout extendable with a double main line on the front of the layout that can be continued on further adjacent modules.

Next is the assembly/disassembly line and yard lead. From here branches a small yard and also a small branch line that would work with various small buildings that I have. I'm very flexible on what needs to be done to make this work other than enlarging the benchwork. I know it's a challenge but I think it's doable.

First thoughts? What would you change and how?

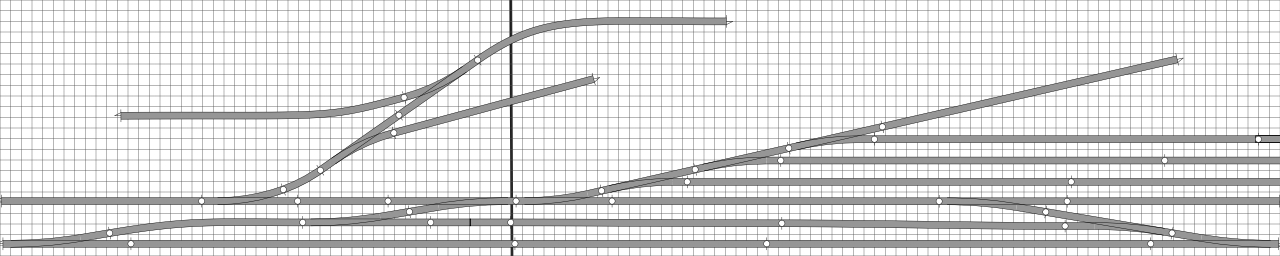

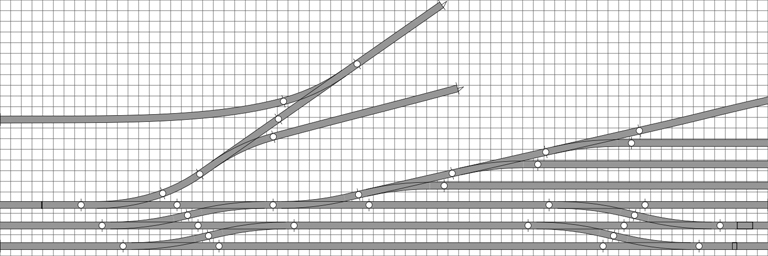

This plan is my first stab at the 2x6ft layout:

I plan to make this layout extendable with a double main line on the front of the layout that can be continued on further adjacent modules.

Next is the assembly/disassembly line and yard lead. From here branches a small yard and also a small branch line that would work with various small buildings that I have. I'm very flexible on what needs to be done to make this work other than enlarging the benchwork. I know it's a challenge but I think it's doable.

First thoughts? What would you change and how?

Last edited by a moderator: