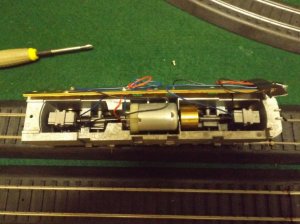

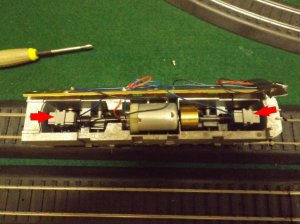

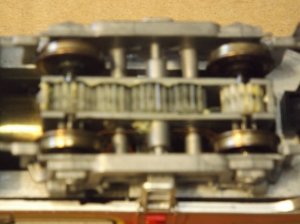

I have a Walthers Trainline Alco FA-1 which is not running as well as I expected - maybe its okay but I just need another opinion.

How do you know if there is a problem with the motor - how do you gauge what is should be capable of? It's pretty heavy for a small loco at 1lb so maybe its just a weight issue.

It does run really well at slow speeds - but I don''t need it running at a snails pace all the time

Also it need horns for the top and I don't know what type I should replace them with.

Can anyone help me out?

P.S. I'm a newbie - so any help that would expand my knowledge will be much appreciated.

P.P.S. I hope this is posted in the correct forum - I posted it in general discussion which I guess was wrong.

How do you know if there is a problem with the motor - how do you gauge what is should be capable of? It's pretty heavy for a small loco at 1lb so maybe its just a weight issue.

It does run really well at slow speeds - but I don''t need it running at a snails pace all the time

Also it need horns for the top and I don't know what type I should replace them with.

Can anyone help me out?

P.S. I'm a newbie - so any help that would expand my knowledge will be much appreciated.

P.P.S. I hope this is posted in the correct forum - I posted it in general discussion which I guess was wrong.