I'm returning to this idea that I suggested back a few weeks ago,...a swinging frog I think it would be called?

railandsail wrote:

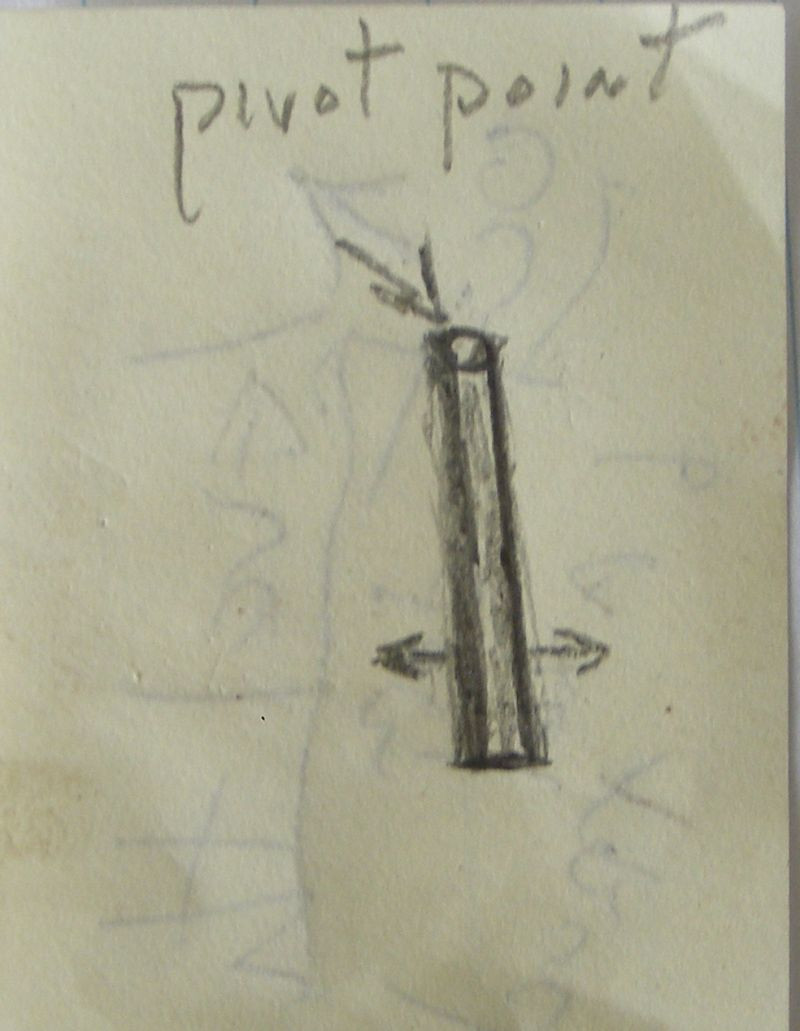

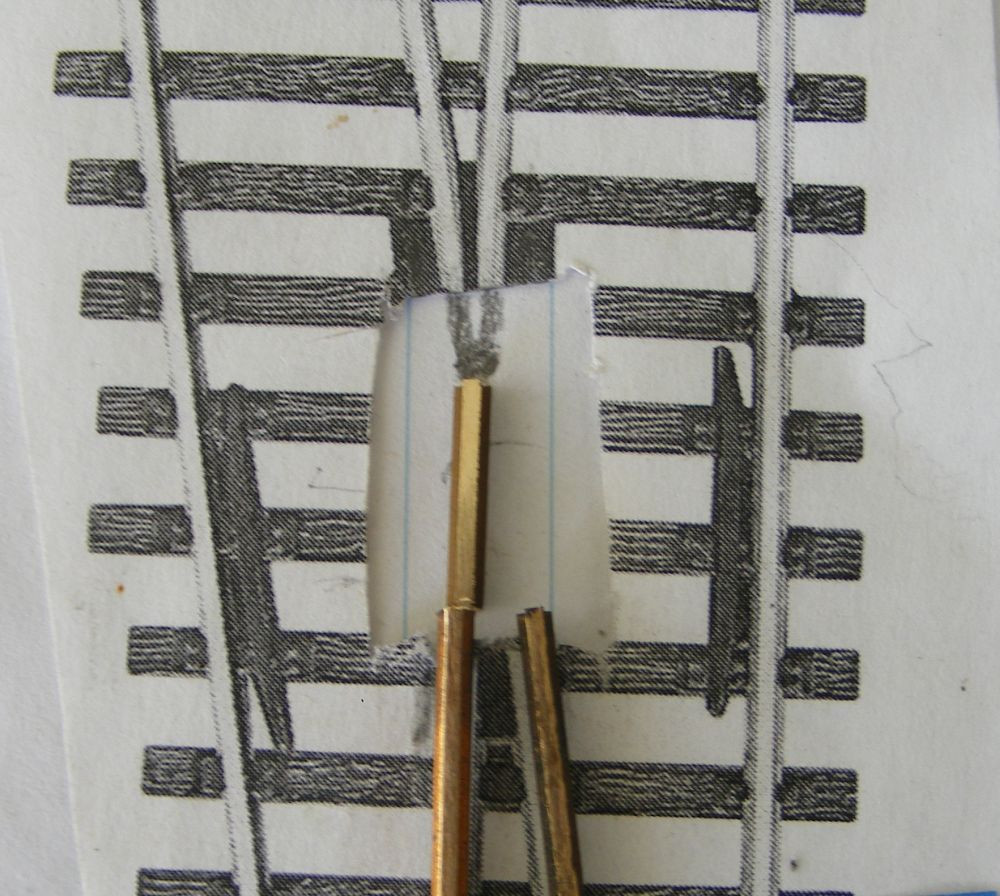

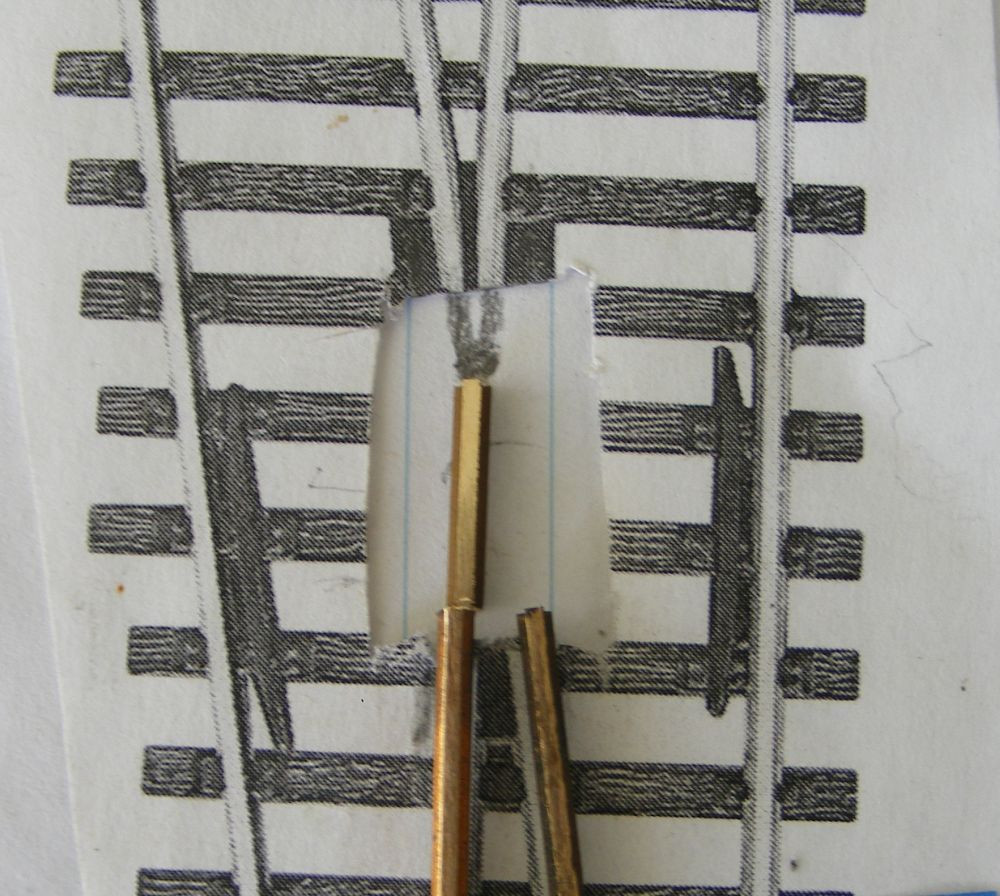

Okay this is just a really rough sketch at the moment, but perhaps it conveys the thought,...my swinging frog.

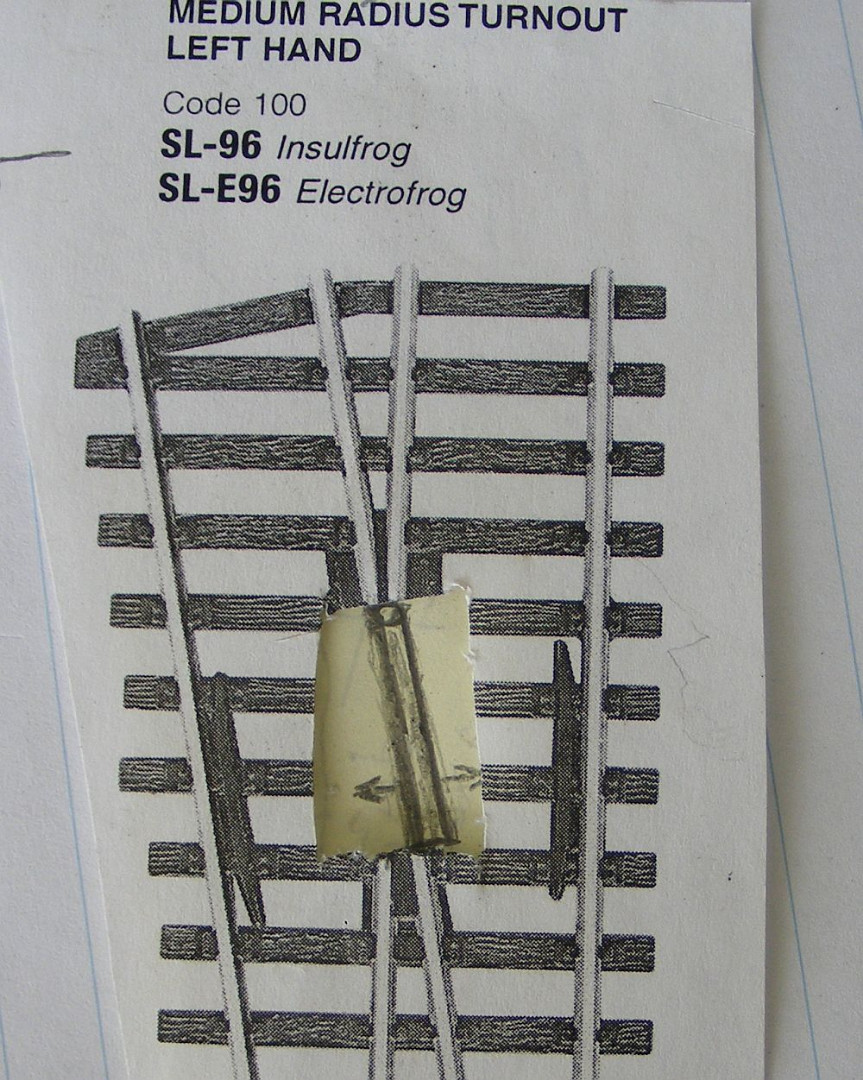

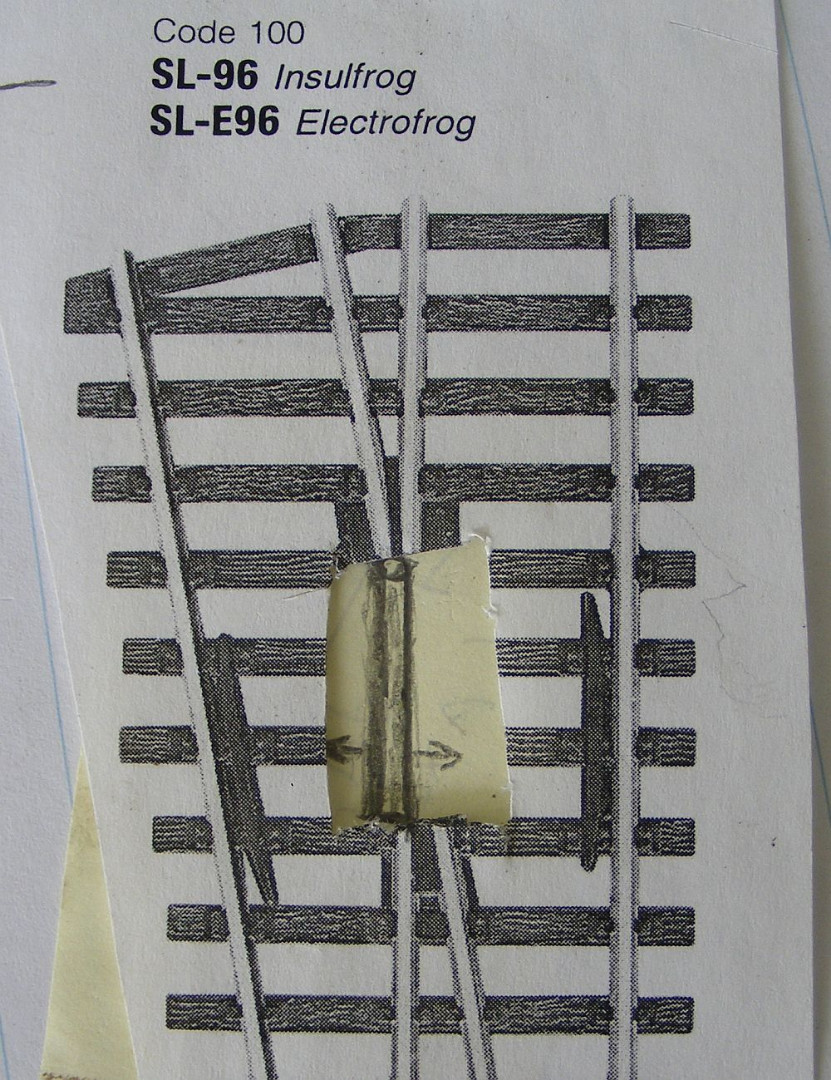

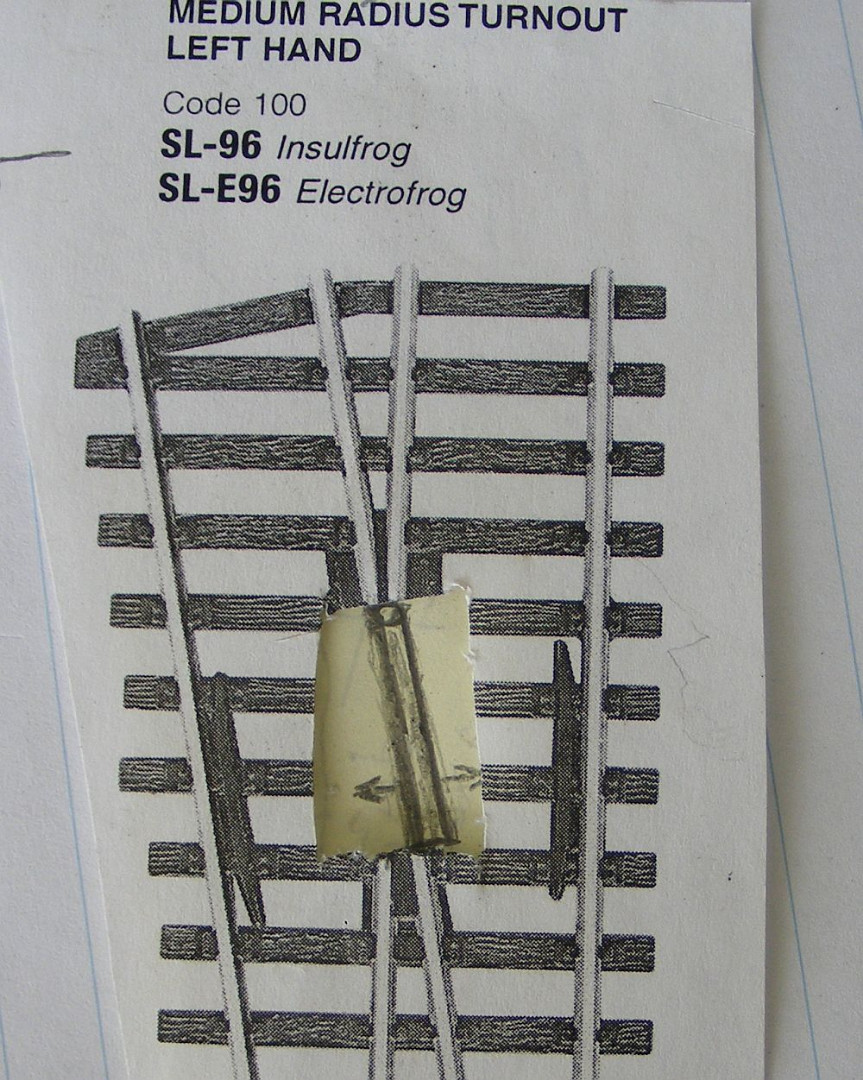

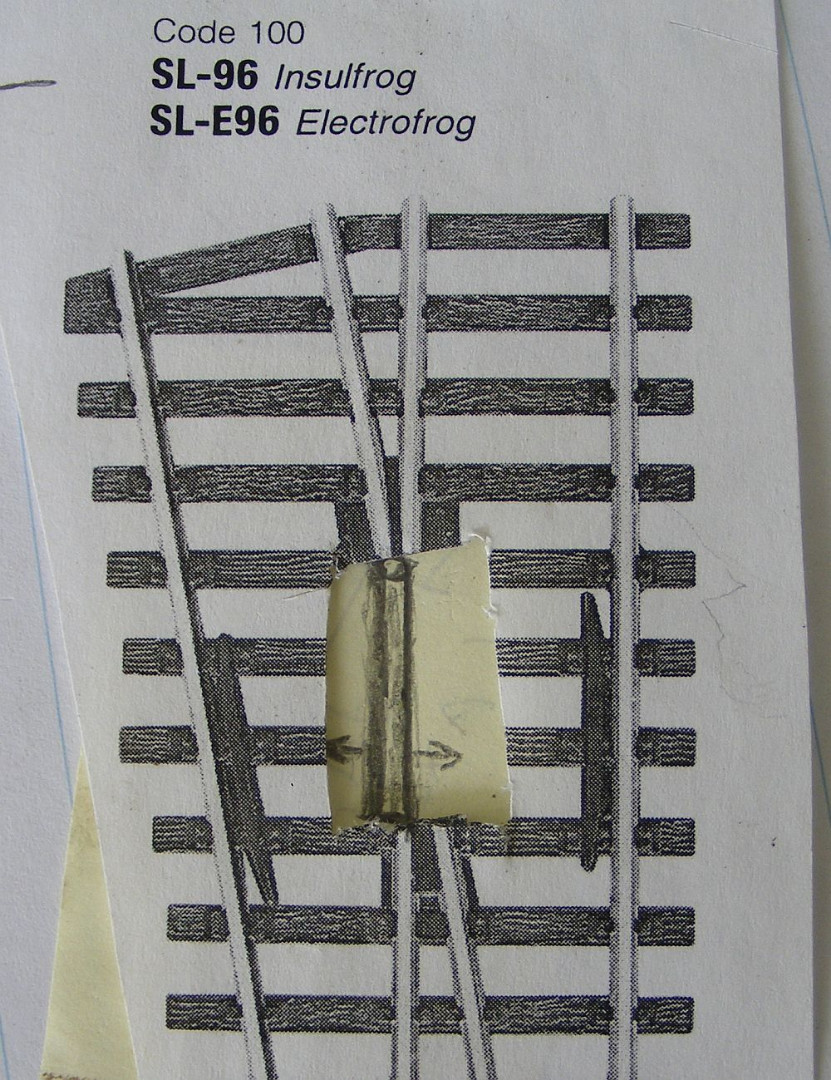

I cut out the location of the stock frog area on a Peco medium radius turnout, and inserted a plain sheet of yellow post-it note behind it

The new 'frog' would be that solid piece of metal that wold rotate around the 'pin' at the one end (circular pin shown) . It would swing from one side to the other and its two sides would line up the inner faces of the tracks in either of the 2 directions. It would allow the wheels of the rolling stock to roll over either of its solid metal edges,...thus a true GapLess turnout.

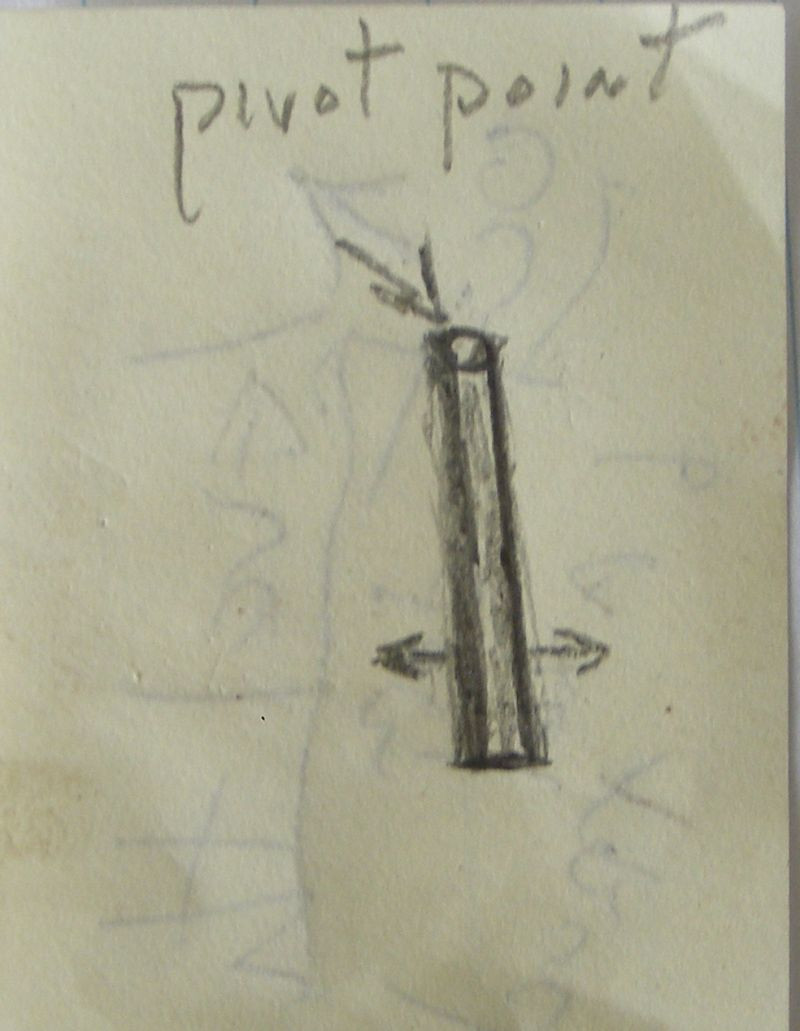

I think I described this incorrectly in my original posting, "The new 'frog' would be that solid piece of metal that wold rotate around the 'pin' at the one end (circular pin shown)". It would NOT rotate around that pin, but rather be a part of the pin,....

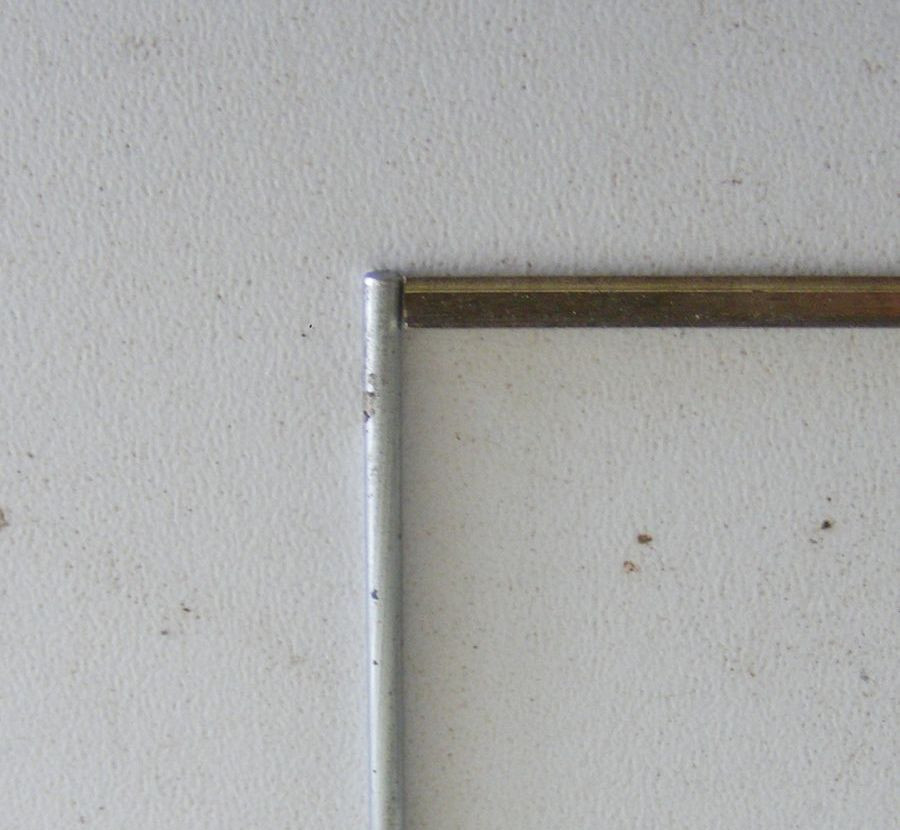

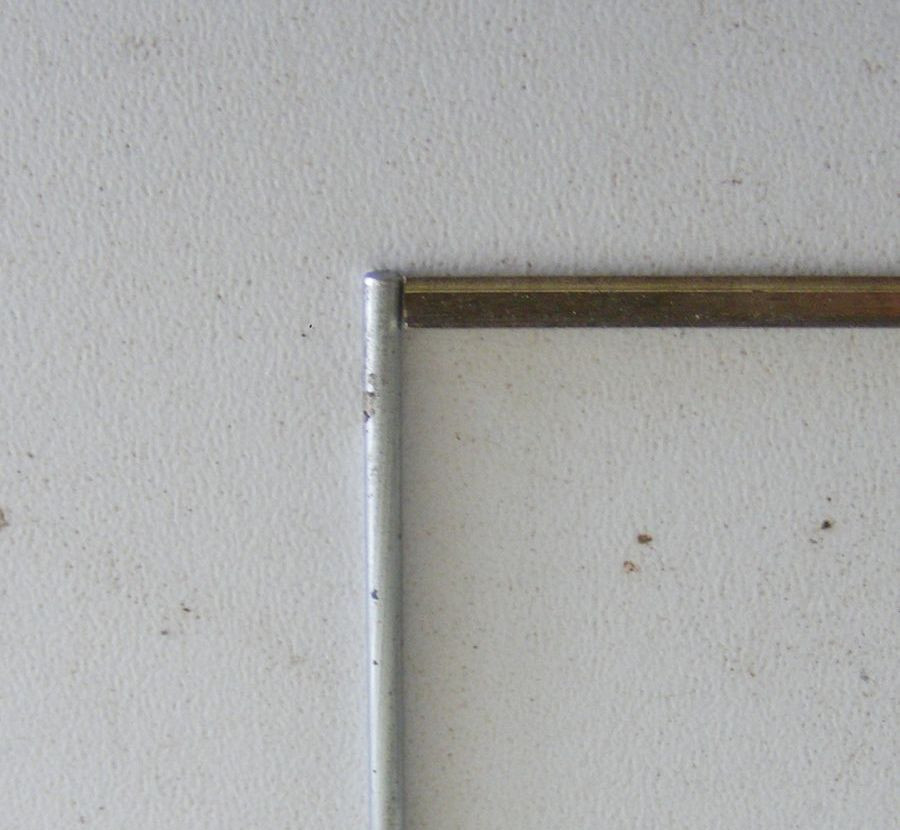

My frog would be all one piece,...the short piece of rail attached permanently to a circular pin at one end,...something akin to this...

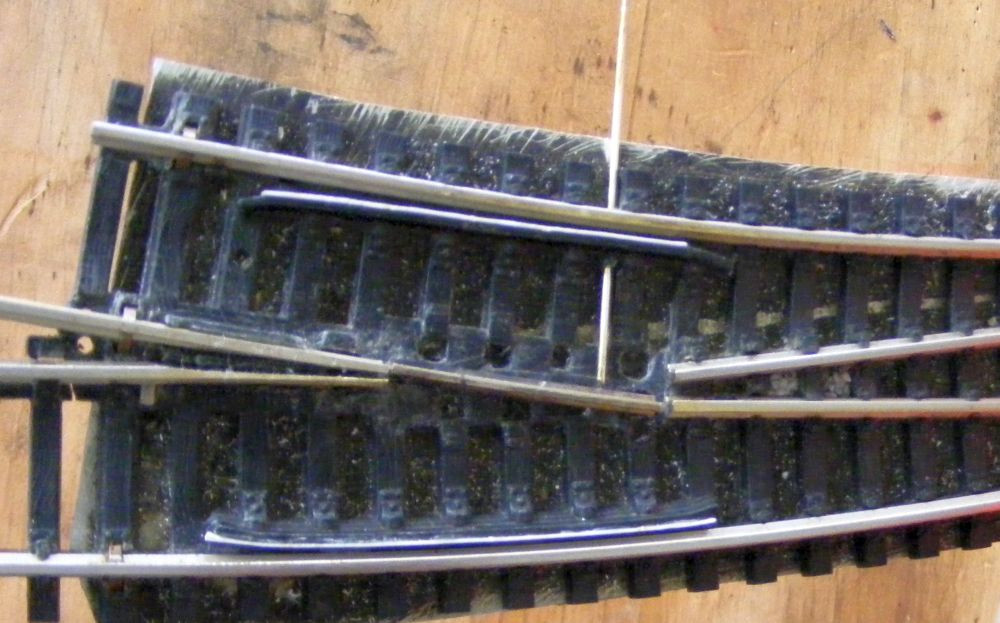

That vertical pin must be a true 90 degrees to the rail piece. It accomplishes several things;

1) it assures the frog rail swings in an exact level manner

2) it keeps that frog rail from twisting over

3) it could be longer, stretching down thru the deck work, thus even more stability,... and maybe be rotated ever so slightly to rotate the frog rail

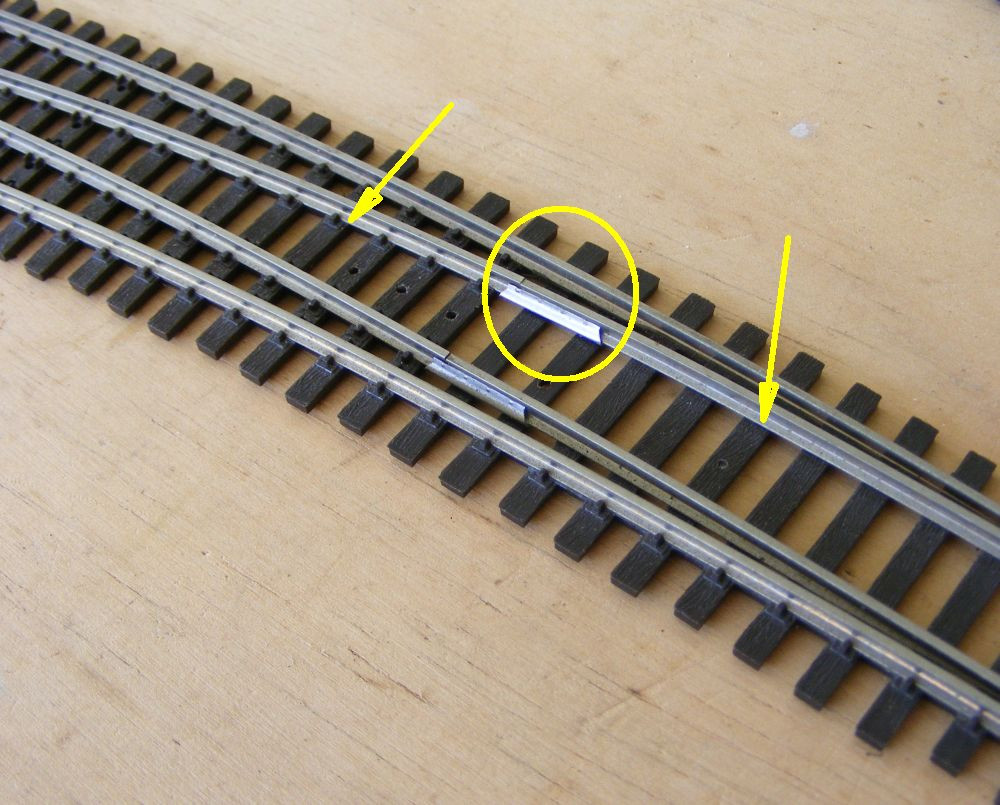

Here is the general configuration,..

Wing/Guard rails could be added around that swing frog, and might even be applied in such a manner to limit the swing of that frog piece to either side.

EDITIED: BTW the circular pin is NOT attached to those rails exiting the frog area. it is only attached to the short swing frog rail.

railandsail wrote:

Okay this is just a really rough sketch at the moment, but perhaps it conveys the thought,...my swinging frog.

I cut out the location of the stock frog area on a Peco medium radius turnout, and inserted a plain sheet of yellow post-it note behind it

The new 'frog' would be that solid piece of metal that wold rotate around the 'pin' at the one end (circular pin shown) . It would swing from one side to the other and its two sides would line up the inner faces of the tracks in either of the 2 directions. It would allow the wheels of the rolling stock to roll over either of its solid metal edges,...thus a true GapLess turnout.

I think I described this incorrectly in my original posting, "The new 'frog' would be that solid piece of metal that wold rotate around the 'pin' at the one end (circular pin shown)". It would NOT rotate around that pin, but rather be a part of the pin,....

My frog would be all one piece,...the short piece of rail attached permanently to a circular pin at one end,...something akin to this...

That vertical pin must be a true 90 degrees to the rail piece. It accomplishes several things;

1) it assures the frog rail swings in an exact level manner

2) it keeps that frog rail from twisting over

3) it could be longer, stretching down thru the deck work, thus even more stability,... and maybe be rotated ever so slightly to rotate the frog rail

Here is the general configuration,..

Wing/Guard rails could be added around that swing frog, and might even be applied in such a manner to limit the swing of that frog piece to either side.

EDITIED: BTW the circular pin is NOT attached to those rails exiting the frog area. it is only attached to the short swing frog rail.

![[age%28274%29] [age%28274%29]](/forum/proxy.php?image=https%3A%2F%2Fd28lcup14p4e72.cloudfront.net%2F259338%2F7351431%2Fage%2528274%2529.png&hash=947b11fe5c998449306ee31fe83f7625)

![[age%28277%29] [age%28277%29]](/forum/proxy.php?image=https%3A%2F%2Fd28lcup14p4e72.cloudfront.net%2F259338%2F7351434%2Fage%2528277%2529.png&hash=f23521ec2efe609138341c5de90f58d2)

![[age%28269%29] [age%28269%29]](/forum/proxy.php?image=https%3A%2F%2Fd28lcup14p4e72.cloudfront.net%2F259338%2F7412634%2Fage%2528269%2529.png&hash=4adf8c9eda52574cae2194643bea5a5d)

![[mcnk2s] [mcnk2s]](/forum/proxy.php?image=https%3A%2F%2Fwww.proto87.com%2Fmedia%2Fmcnk2s.jpg&hash=d78734151506b72b5a30b593e126536a)

![[mtub2s] [mtub2s]](/forum/proxy.php?image=https%3A%2F%2Fwww.proto87.com%2Fmedia%2Fmtub2s.jpg&hash=98efd3e8a80900099caefc66e0303a86)

![[%252C%2520ps] [%252C%2520ps]](/forum/proxy.php?image=https%3A%2F%2Fd28lcup14p4e72.cloudfront.net%2F259338%2F7380299%2F%25252C%252520ps.jpg&hash=7d10e4f434a6064c0e08dd424955f587)