flyboy2610

Loveably weird

It's a chilly, cloudy, windy day today. This kind of weather often makes my right knee act up, so working under the layout on the wiring is not something I want to do today. Maybe tomorrow.

I decided instead to start work on a project I've been meaning to get around to for quite some time: re-motoring an old Athearn TR5A, and adding DCC and sound.

The TR5A was a switch engine produced in 1951 and 1952. The design was based on the SW9, and was used in a cow/calf configuration. A total of 10 A units were built, and 12 B units. Mine is #1870, and I do not have a B unit. I do, however, have a extra shell, so I'm going to be on the hunt for a chassis I can use to kitbash a B unit.

These are the old style Blue Box locomotives with metal side-frames attached to the trucks, and the open frame gray motors. I have heard those motors referred to as "baby elephant" motors! I checked the stall current of the motor, and while I don't recall exactly what it was, it was fairly high, even after a thorough tune up. So if I want to go DCC, which my layout is, a re-motor is in order.

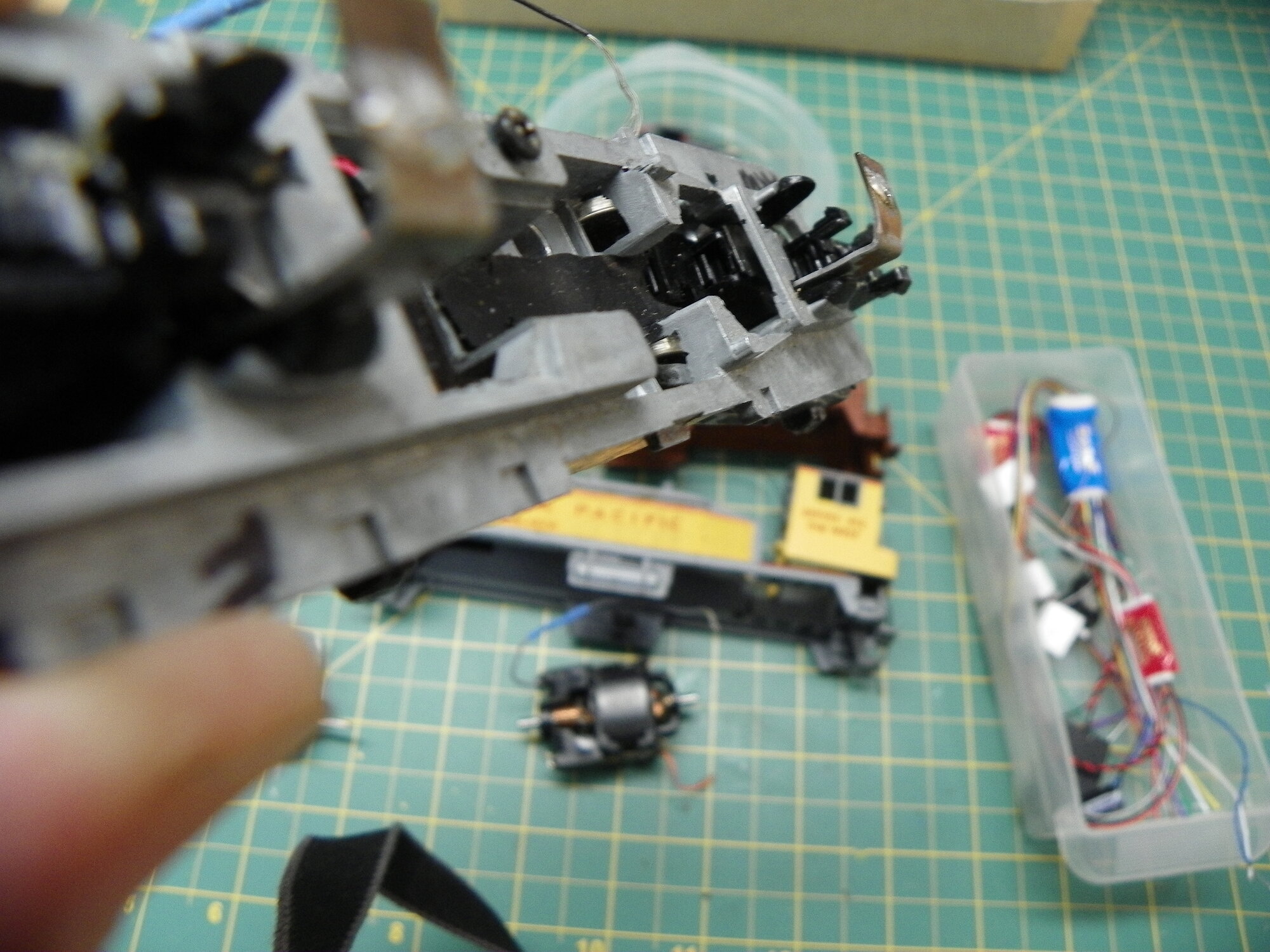

This is what I'm working with:

I have already had a decoder in it once, but it didn't work too well. The headlight has an LED in it, but I never did the back up light. You can see how the shell attaches with horizontal tabs, rather than round nubs as the newer Blue Box locomotives have. The fiddly bits are in the KFC container. Those containers (after you have eaten the contents, of course) come in quite handy for purposes such as this. I have 3 Digitrax N scale sound decoders, and 1 HO Digitrax sound decoder. I haven't decided whether to use any of those, or go with a Soundtraxx Tsunami. I'm leaning towards the Soundtraxx, probably a board style decoder.

The black can motor is what is going in. I bought 10 of those motor on FleaBay several years ago, and never got round to installing any! Gonna have to rectify that oversight. I am also going to get rid of the flywheels. Trying to keep them would cause more problems than it would solve, so they're going bye-bye!

For the driveshaft I am going to use silicone tubing. Pictured is Du-Bro #221 small diameter RC fuel line. Interior diameter is 1/16" (.0625), or very close to 1-1/2mm. The motor shaft is .079, and the worm gear shaft is .092, so the fit should be fine. Before I install the tubing, I'm going to give the shafts a rub with some sand paper to roughen the surface, so the tubing should hold even better.

To get the motor installed anywhere even close to where it needs to be, some modification needs to be done to the frame. As it is, the motor sits much to high, so the frame will have to be milled down. All the milling will have to be done to the front half of the frame.

Here is a pic of the back half of the frame:

As you can see, if I try to mill any of that down, it will seriously weaken the structure of the frame! Can't have that, now, can we?

Here is a pic of the front of the frame. You can see there is much more material to work with on this end:

I don't recall why I installed that screw. I use the old front headlight post as the spot to solder the wire for frame side power.

More to come!

I decided instead to start work on a project I've been meaning to get around to for quite some time: re-motoring an old Athearn TR5A, and adding DCC and sound.

The TR5A was a switch engine produced in 1951 and 1952. The design was based on the SW9, and was used in a cow/calf configuration. A total of 10 A units were built, and 12 B units. Mine is #1870, and I do not have a B unit. I do, however, have a extra shell, so I'm going to be on the hunt for a chassis I can use to kitbash a B unit.

These are the old style Blue Box locomotives with metal side-frames attached to the trucks, and the open frame gray motors. I have heard those motors referred to as "baby elephant" motors! I checked the stall current of the motor, and while I don't recall exactly what it was, it was fairly high, even after a thorough tune up. So if I want to go DCC, which my layout is, a re-motor is in order.

This is what I'm working with:

I have already had a decoder in it once, but it didn't work too well. The headlight has an LED in it, but I never did the back up light. You can see how the shell attaches with horizontal tabs, rather than round nubs as the newer Blue Box locomotives have. The fiddly bits are in the KFC container. Those containers (after you have eaten the contents, of course) come in quite handy for purposes such as this. I have 3 Digitrax N scale sound decoders, and 1 HO Digitrax sound decoder. I haven't decided whether to use any of those, or go with a Soundtraxx Tsunami. I'm leaning towards the Soundtraxx, probably a board style decoder.

The black can motor is what is going in. I bought 10 of those motor on FleaBay several years ago, and never got round to installing any! Gonna have to rectify that oversight. I am also going to get rid of the flywheels. Trying to keep them would cause more problems than it would solve, so they're going bye-bye!

For the driveshaft I am going to use silicone tubing. Pictured is Du-Bro #221 small diameter RC fuel line. Interior diameter is 1/16" (.0625), or very close to 1-1/2mm. The motor shaft is .079, and the worm gear shaft is .092, so the fit should be fine. Before I install the tubing, I'm going to give the shafts a rub with some sand paper to roughen the surface, so the tubing should hold even better.

To get the motor installed anywhere even close to where it needs to be, some modification needs to be done to the frame. As it is, the motor sits much to high, so the frame will have to be milled down. All the milling will have to be done to the front half of the frame.

Here is a pic of the back half of the frame:

As you can see, if I try to mill any of that down, it will seriously weaken the structure of the frame! Can't have that, now, can we?

Here is a pic of the front of the frame. You can see there is much more material to work with on this end:

I don't recall why I installed that screw. I use the old front headlight post as the spot to solder the wire for frame side power.

More to come!