You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cn Gp38-2w

- Thread starter CP9302

- Start date

railflyermodel

Member

Couplers

Guys,

I have been working on the coupler issue. The biggest problem is that this system is scale based, not like RTR so nothing has ever been developed for it by the coupler manufacturers. Why put out something for a product that doesn't exist?

So I have emailed Sargent and I am trying to get a coupler based on his design that will work with my coupler pocket. Also I am going to do the same for Kadee. A simple solution is to machine a new shank and attach it to an existing coupler head. Its a small hurdle, but I would rather leave the couplers to a coupler manufacturer so I can concentrate on other components.

If you are interested in this system or have it, email both Kadee and Sargent. They will not act unless they are convinced that there is a market for the product, my words alone might not be enough. Get involved and it can be done sooner rather than later.

So until you see a real 8" x 8" shank on a coupler there will be no drop fit. Its quite simple in design to make this work. If the coupler guys do not pick this up, we'll tool something ourselves. Trucks are next on the agenda.

CJH

Guys,

I have been working on the coupler issue. The biggest problem is that this system is scale based, not like RTR so nothing has ever been developed for it by the coupler manufacturers. Why put out something for a product that doesn't exist?

So I have emailed Sargent and I am trying to get a coupler based on his design that will work with my coupler pocket. Also I am going to do the same for Kadee. A simple solution is to machine a new shank and attach it to an existing coupler head. Its a small hurdle, but I would rather leave the couplers to a coupler manufacturer so I can concentrate on other components.

If you are interested in this system or have it, email both Kadee and Sargent. They will not act unless they are convinced that there is a market for the product, my words alone might not be enough. Get involved and it can be done sooner rather than later.

So until you see a real 8" x 8" shank on a coupler there will be no drop fit. Its quite simple in design to make this work. If the coupler guys do not pick this up, we'll tool something ourselves. Trucks are next on the agenda.

CJH

CP9302

Member

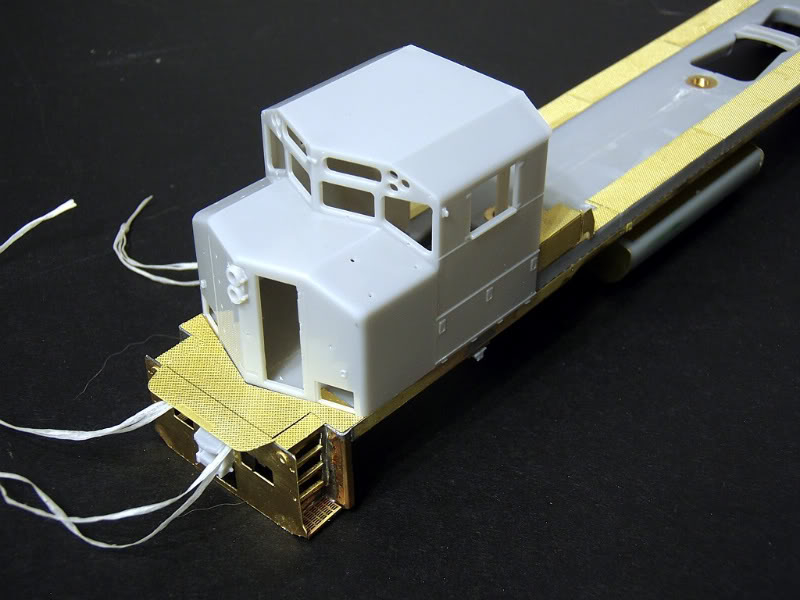

A big box of goodies arrived from Chris at Railflyer this week! So that means a little more progress on this project.

Chris included most of the wide cab kit in this shipment. He is still waiting on the photo etch components of the cab. This cab is beautiful! It is the cab I've wished Cannon would make! Once the photo etch goes on, it will look better then any wide cab on the market. And the wide cab kit comes with everything you need for the cab, no need to buy any other detail parts for the cab, they all come with the kit.

I glued down the front walkway tread first, then set the cab in place and marked where the walkway blower duct would go. I glued this on and then put the tread on the duct and along that side. The rear tread went on next and then I worked from the rear back to the cab for the remainder of the tread. I also glued the electrical box behind the cab on the duct. The cab is just set in place right not. It looks really good, but will not be glued on until the rest of the hood is ready too.

I also build some of the other parts I have for this kit.

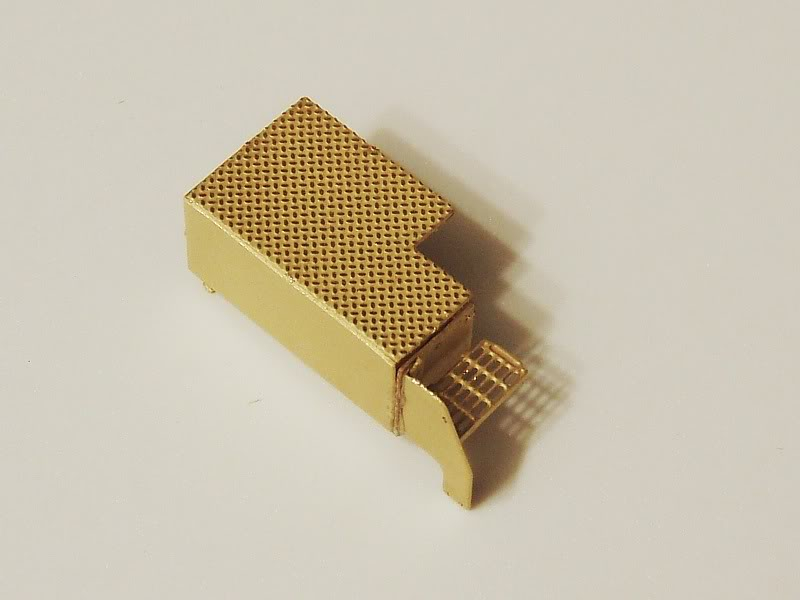

Here is the electrical box sub assembly. The detail on this part is outstanding! Tread plate, step grating, conduit underneath and mounting brackets. All photo etched brass. I chose to assemble this part with CA instead of solder.

Top of electrical box:

Bottom of electrical box:

The Brake Wheel recess is photo etched brass. I soldered this together, but CA would also work. I'll add a Cannon brake wheel after painting and weathering.

The Snow Shields are also photo etched brass. I soldered these together. The small holes are pre-drilled so you can easily add a lift ring to each snow shield.

Chris included most of the wide cab kit in this shipment. He is still waiting on the photo etch components of the cab. This cab is beautiful! It is the cab I've wished Cannon would make! Once the photo etch goes on, it will look better then any wide cab on the market. And the wide cab kit comes with everything you need for the cab, no need to buy any other detail parts for the cab, they all come with the kit.

I glued down the front walkway tread first, then set the cab in place and marked where the walkway blower duct would go. I glued this on and then put the tread on the duct and along that side. The rear tread went on next and then I worked from the rear back to the cab for the remainder of the tread. I also glued the electrical box behind the cab on the duct. The cab is just set in place right not. It looks really good, but will not be glued on until the rest of the hood is ready too.

I also build some of the other parts I have for this kit.

Here is the electrical box sub assembly. The detail on this part is outstanding! Tread plate, step grating, conduit underneath and mounting brackets. All photo etched brass. I chose to assemble this part with CA instead of solder.

Top of electrical box:

Bottom of electrical box:

The Brake Wheel recess is photo etched brass. I soldered this together, but CA would also work. I'll add a Cannon brake wheel after painting and weathering.

The Snow Shields are also photo etched brass. I soldered these together. The small holes are pre-drilled so you can easily add a lift ring to each snow shield.

master_train

Member

CP9302, thats is awesome! cant wait to see it when its done

are you going to paint it the cn's zebra scheme?

are you going to paint it the cn's zebra scheme?

CP9302

Member

CP9302, thats is awesome! cant wait to see it when its done

are you going to paint it the cn's zebra scheme?

CN has a different paint scheme!?!?!

Yes, I plan to do the zebra, well faded though. I'm 99% sure it will be 4760.

master_train

Member

well they have some locomotives painted in black-red scheme without the zebra stripes

anyway, good job!

anyway, good job!

railflyermodel

Member

Guys,

Fred is doing an outstanding job with his parts!

Here's an update on the Wide Cab. Laser cut glass samples are in transit. Once they are test fitted the production run will be done within a few days.

I have submitted the rear doors which are multi-layer etched in brass. There are two additional frets for the photo-etch that are in progress. An RFQ is out for pre-bent grabs.

Things are winding down on this project, we still need your help and support, what we've got so far is helping out a lot.

Thanks.

Christopher Howard

Railflyer Model Prototypes Inc.

www.railflyermodelprototypes.com

Fred is doing an outstanding job with his parts!

Here's an update on the Wide Cab. Laser cut glass samples are in transit. Once they are test fitted the production run will be done within a few days.

I have submitted the rear doors which are multi-layer etched in brass. There are two additional frets for the photo-etch that are in progress. An RFQ is out for pre-bent grabs.

Things are winding down on this project, we still need your help and support, what we've got so far is helping out a lot.

Thanks.

Christopher Howard

Railflyer Model Prototypes Inc.

www.railflyermodelprototypes.com

CP9302

Member

The summer months put a damper on my modeling time, and I have just started working on stuff again in the last couple of weeks. I've have spent several hours working on this project again.

Christopher at Railflyer has released all the parts to finish the wide cab kit now. The photo etch parts are out standing, and really elevate this cab above all others. I have most of the parts added to my cab now. There are a couple more parts to apply to the roof, rain guards and antennae. I will paint and apply the window frames and gaskets after painting, but they are all included in the kit, as well as "glass" for the windows. A beautiful set of photo etched windshield wipers are also part of the kit.

Christopher at Railflyer has released all the parts to finish the wide cab kit now. The photo etch parts are out standing, and really elevate this cab above all others. I have most of the parts added to my cab now. There are a couple more parts to apply to the roof, rain guards and antennae. I will paint and apply the window frames and gaskets after painting, but they are all included in the kit, as well as "glass" for the windows. A beautiful set of photo etched windshield wipers are also part of the kit.

CP9302

Member

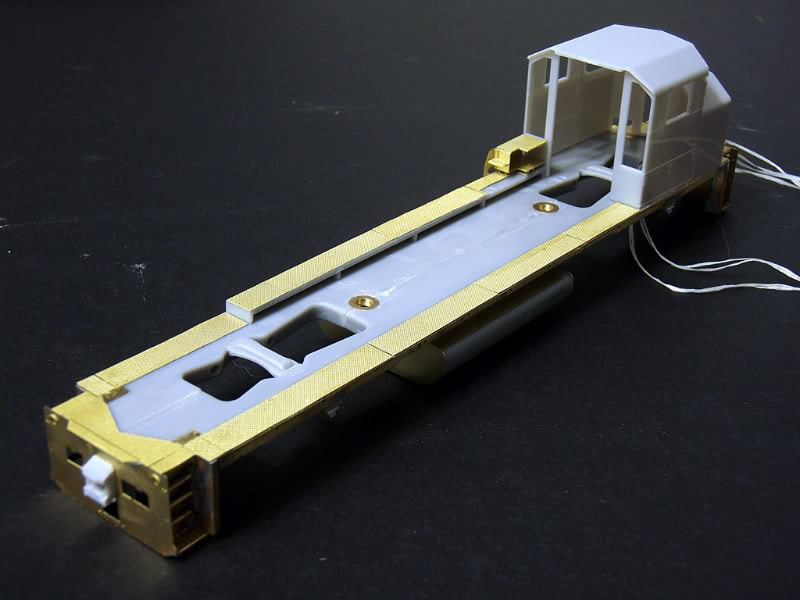

I have also done a lot of work on the underframe detailing. I added an underframe bracing kit, which is great as it has guide holes for adding air tanks, air filters and other bracing on it.

I also added all the traction motor cabling using the photo etched pillow blocks and fine solder as the cables. It is a lot of work to add the cables, but they look excellent! The vent valves have also been added to the frame. I'll be adding the air lines and air tanks next.

I also added all the traction motor cabling using the photo etched pillow blocks and fine solder as the cables. It is a lot of work to add the cables, but they look excellent! The vent valves have also been added to the frame. I'll be adding the air lines and air tanks next.

CP9302

Member

Fred, lots of nice work there. Between your work and Railflyer products, it almost makes me want to take up Canadian modeling.

You can build US prototypes with Railflyer kits too! Not to mention, lots of former CN Widecabs have migrated south for warmer weather!