It turns out I have found 3 such locos in my stowage cargo trailer,..that I had almost forgotten I had.

1) One of them is a single-motor version of the 70 ton GE. It is running fine, but i don't think I will keep it, as I have a bunch of Atlas & Proto switchers

2) Two of them are dual-motor versions of the 44 ton GE.

a) the brand new C&O one is running beautify.

b) the Western Md one is clicking, but running OK,.....

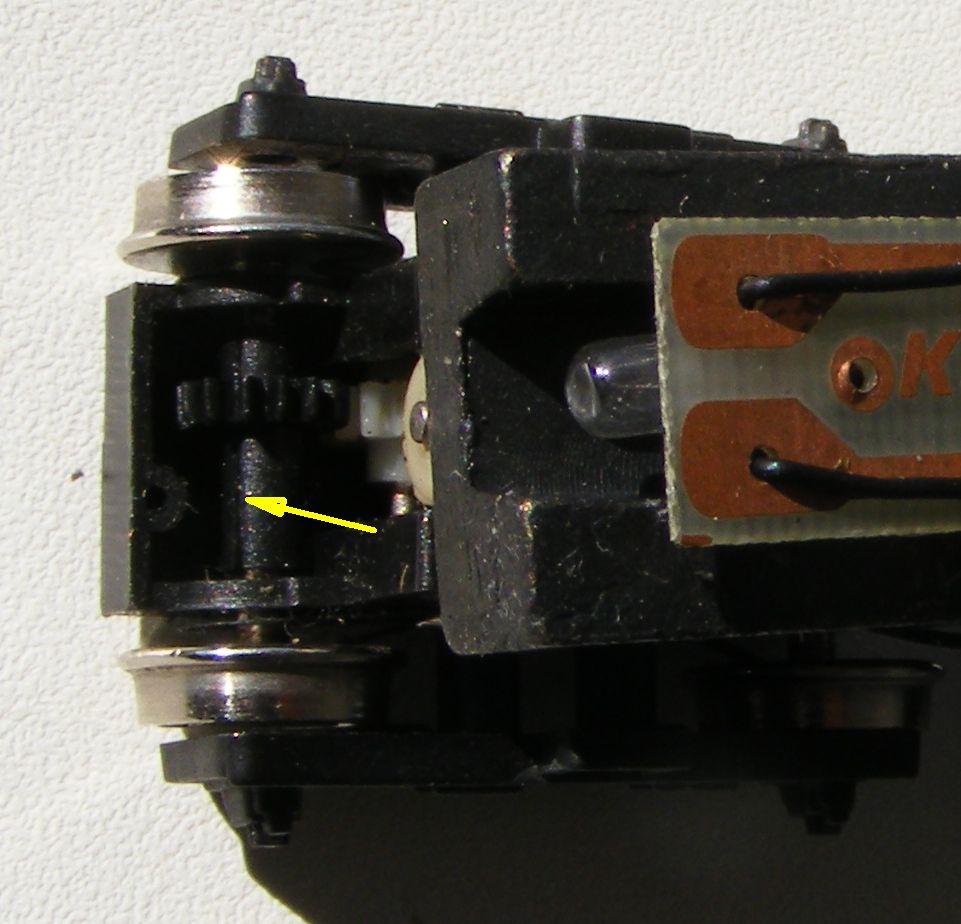

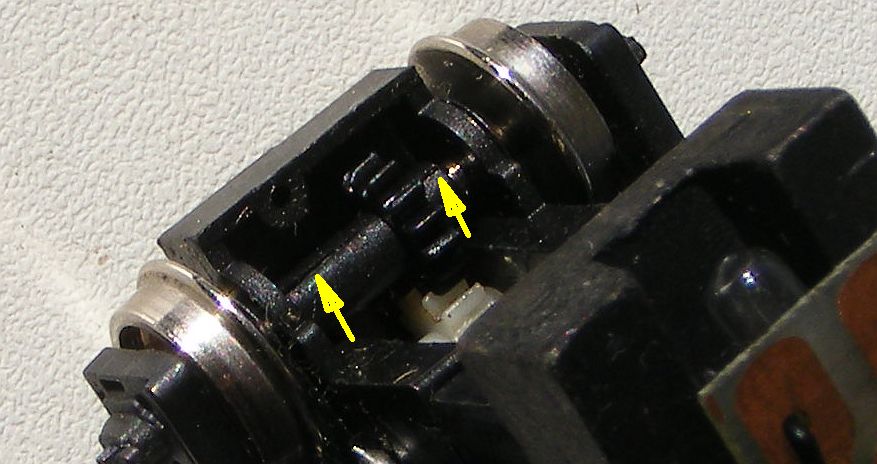

Clicking would indicate a split axle gear, and sure enough that is the case,..

How does one get the trucks apart to get these wheels sets out to make a repair?? Perhaps I am a bit dense, but I don't really see how?

1) One of them is a single-motor version of the 70 ton GE. It is running fine, but i don't think I will keep it, as I have a bunch of Atlas & Proto switchers

2) Two of them are dual-motor versions of the 44 ton GE.

a) the brand new C&O one is running beautify.

b) the Western Md one is clicking, but running OK,.....

Clicking would indicate a split axle gear, and sure enough that is the case,..

How does one get the trucks apart to get these wheels sets out to make a repair?? Perhaps I am a bit dense, but I don't really see how?