You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Union Pacific Soggy Bottoms Subdivision (HO scale)

- Thread starter flyboy2610

- Start date

flyboy2610

Loveably weird

Well, I finally got the bridge deck painted! I didn't airbrush it. I just used some Rustoleum self etching primer on it. The color isn't a perfect match, but it's close. I masked off the upper part of the bridge as well as I could, but still got some seepage along the bottom where the deck is. I'll just weather the bridge well, and it won't be very noticeable at all.

I also got the German two man mini sub for under the bridge. Yeah, I'm weird. Deal with it! I got it from M.B. Klein. They did a very good job of packing the kit box into an outer box. The problem was with the way the kit manufacturer packaged the kit in the original box. Everything was secured with thread looped under the cardboard! I'm sure the kit left Klein's in great shape, but by the time it got to me it was mostly loose in the box. As you can see some repair work is in order. All 3 torpedoes are now in 2 parts, one of the diving planes is broken off, and a small antenna on the sub is broken off. I can't blame Klein's, I just wish UPS wasn't quite so ham-fisted with the way they do things! I'll glue it all back together this afternoon.

I also got the German two man mini sub for under the bridge. Yeah, I'm weird. Deal with it! I got it from M.B. Klein. They did a very good job of packing the kit box into an outer box. The problem was with the way the kit manufacturer packaged the kit in the original box. Everything was secured with thread looped under the cardboard! I'm sure the kit left Klein's in great shape, but by the time it got to me it was mostly loose in the box. As you can see some repair work is in order. All 3 torpedoes are now in 2 parts, one of the diving planes is broken off, and a small antenna on the sub is broken off. I can't blame Klein's, I just wish UPS wasn't quite so ham-fisted with the way they do things! I'll glue it all back together this afternoon.

Last edited:

goscrewyourselves

I'm the one

A mini sub - what will they come out with next!? And, the bridge looks fine to me.

flyboy2610

Loveably weird

A mini sub - what will they come out with next!? And, the bridge looks fine to me.

Thanks, Tony! I was looking for something to put in the water to make the scene a bit more interesting, and I came across the sub on Klein's website. I didn't have $40 at the time, so I bookmarked it. When I had the money, they were sold out.

I recently got my tax refund, and checked again. This time they had 1. Now they have none because I got the one they had! Why a German 2 man mini sub?

Why not?

goscrewyourselves

I'm the one

Why a German 2 man mini sub?

Why not?

Hope your going to submerge it a little, or maybe have the stern below the water line with the bow springing valiantly and defiantly from the depths

Ooops too much Red October ....

Anyway, it certainly will be a talking point and will achieve your wants of interest, that is for sure.

flyboy2610

Loveably weird

I am gluing the bridge in place with some Liquid Nails heavy duty construction adhesive. Right now I just have the left side of the bridge glued in. When that has dried for 24 hours I will glue the right side down. In addition to the glue I will be putting in 4 #2 x 3/4" Phillips pan head wood screws along each side of the left bridge, and 1 in each end of the right side bridges. Those bridges aren't going anywhere!

I made the needed repairs on the midget sub, and glued a torpedo to each side. This is a resin kit, and CA seems to be the glue of choice for resin kits, so that's what was used. The bottom of the hull sits slightly deeper than the torpedoes, so it leans a bit. A few seconds on the belt of my Harbor Freight special disc/belt sander will fix that. I realize that in reality a surfaced submarine would be sitting low enough in the water that the propeller would be submerged, but I really don't want to to sand that much off the model, so a bit of modeler's license will be employed, and the sub will sit much higher than it really should. Of course, a whole lot of modeler's license is being employed just putting it in the river in the first place!

I made the needed repairs on the midget sub, and glued a torpedo to each side. This is a resin kit, and CA seems to be the glue of choice for resin kits, so that's what was used. The bottom of the hull sits slightly deeper than the torpedoes, so it leans a bit. A few seconds on the belt of my Harbor Freight special disc/belt sander will fix that. I realize that in reality a surfaced submarine would be sitting low enough in the water that the propeller would be submerged, but I really don't want to to sand that much off the model, so a bit of modeler's license will be employed, and the sub will sit much higher than it really should. Of course, a whole lot of modeler's license is being employed just putting it in the river in the first place!

Last edited:

flyboy2610

Loveably weird

Thanks, guys! I like adding 'unique' details to my layout. After all, the main goal is to have fun, right?

One corner of the layout will be occupied by the Rust-Eze Medicated Bumper Ointment plant. (From Disney's Cars movies.) Two of the vehicles will be Luigi and Guido. I found and ordered an HO scale Fiat 500 for Luigi, and found a Kibri 3-wheeled forklift to convert into Guido, but noone has it in stock.

http://video.disney.com/watch/luigi-only-follows-ferraris-4bb39ce9bf8cca8833003b15

One corner of the layout will be occupied by the Rust-Eze Medicated Bumper Ointment plant. (From Disney's Cars movies.) Two of the vehicles will be Luigi and Guido. I found and ordered an HO scale Fiat 500 for Luigi, and found a Kibri 3-wheeled forklift to convert into Guido, but noone has it in stock.

http://video.disney.com/watch/luigi-only-follows-ferraris-4bb39ce9bf8cca8833003b15

Last edited:

goscrewyourselves

I'm the one

Flyboy,

That looks like a "fun" project and will certainly be a unique feature.

That looks like a "fun" project and will certainly be a unique feature.

flyboy2610

Loveably weird

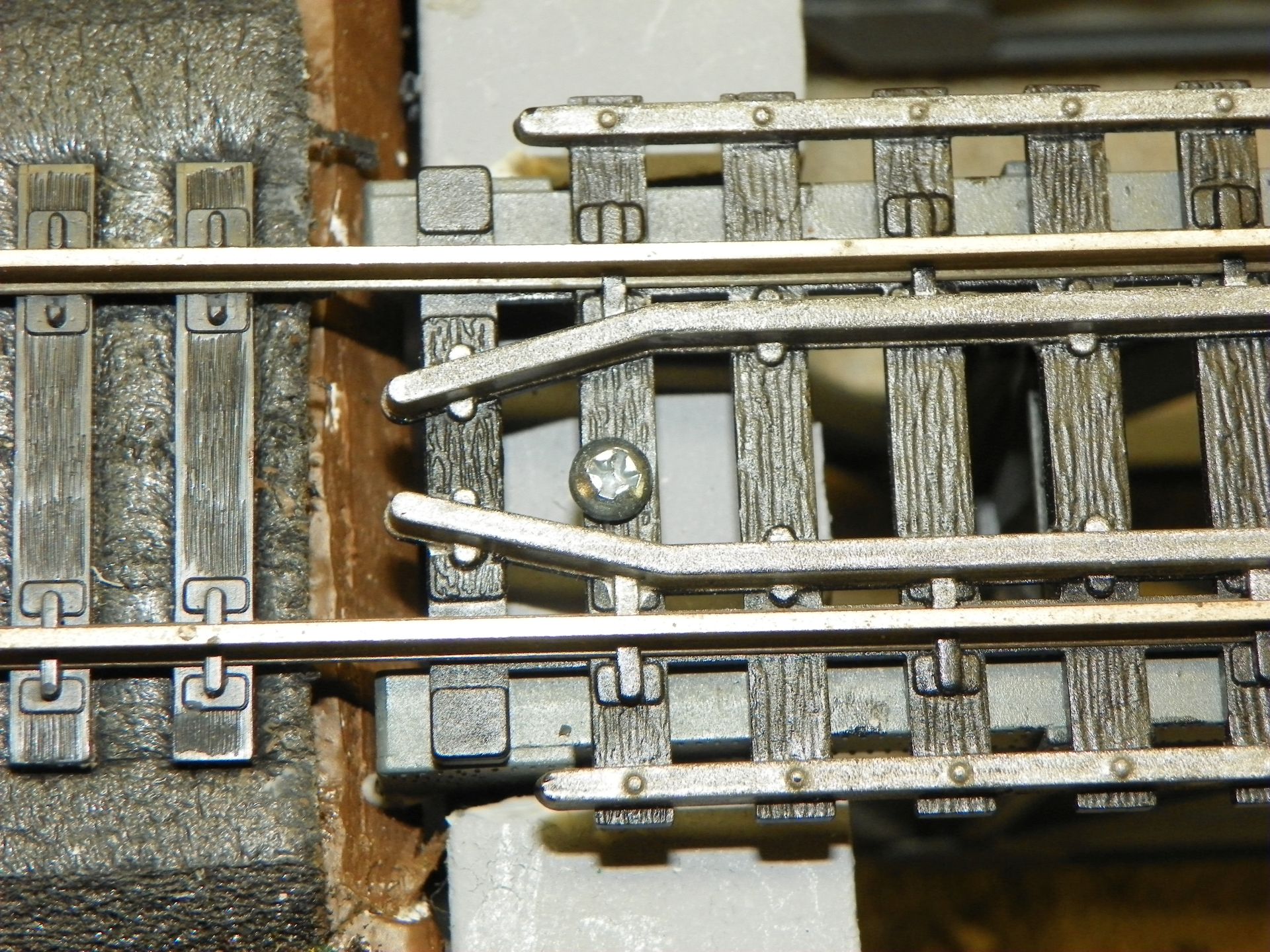

I got the bridge installed on the supports. I used #2 x 3/4 flat-head screws on the river side, and and #2 x 5/8 round-head screws on the sandbar side. I think they stick up a bit too high, though, so I think I'll try to find some pan-head screws instead. I couldn't use flat-head screws on this side, because they have to be countersunk, and there's not enough material in the ties to do that. If I could find some 1" flat-head screws, I could probably do that on the sides, but they would need to be long to get down into the wood. I'll see what I can come up with. Once I fill in the holes with some filler and apply a bit of paint, they shouldn't be too noticeable. I will also give the sandbar side screw shanks some paint since they are out in the open.

The complete bridge:

The river side of the bridge. 4 screws on each side should prevent curling!

The sandbar side. I had to install the screws through the ties, as I can't find any real long #2 screws to go down through the girders and hit wood.

The round-head screws. I can't use flat-head screws here, because there is not enough material to countersink them. I plan to replace these with pan-head screws. I don't like the way these stick up so far.

It's a freezing cold day here today, and a stiff north wind doesn't make it feel any warmer! When it warms up (weatherman says 70 on Thursday!) I plan to decant some Rustoleum primer and paint the shank of the sandbar side screws to make them less obvious. The heads of all the screws will be painted as well.

Of course, with warmer weather comes outdoor projects, so I'll have even LESS time for the layout! But ain't that the way it goes?

The complete bridge:

The river side of the bridge. 4 screws on each side should prevent curling!

The sandbar side. I had to install the screws through the ties, as I can't find any real long #2 screws to go down through the girders and hit wood.

The round-head screws. I can't use flat-head screws here, because there is not enough material to countersink them. I plan to replace these with pan-head screws. I don't like the way these stick up so far.

It's a freezing cold day here today, and a stiff north wind doesn't make it feel any warmer! When it warms up (weatherman says 70 on Thursday!) I plan to decant some Rustoleum primer and paint the shank of the sandbar side screws to make them less obvious. The heads of all the screws will be painted as well.

Of course, with warmer weather comes outdoor projects, so I'll have even LESS time for the layout! But ain't that the way it goes?

Last edited:

flyboy2610

Loveably weird

I forgot to mention: Look who showed up yesterday:

Yes, it's Luigi and Guido. They are about the right size for O scale, but way too big for HO. I bought them for reference. My HO scale Fiat 500 came as well. That will become Luigi. I think Guido is going to be a custom build. The small Kibri forklift I found online just won't work for him.

I don't know when I'll get to this project, though. Too many other things around here needing done first.

Yes, it's Luigi and Guido. They are about the right size for O scale, but way too big for HO. I bought them for reference. My HO scale Fiat 500 came as well. That will become Luigi. I think Guido is going to be a custom build. The small Kibri forklift I found online just won't work for him.

I don't know when I'll get to this project, though. Too many other things around here needing done first.

Last edited:

flyboy2610

Loveably weird

This place is a PIT!!

A few hours of work, and it's much better! I just knew there was a model railroad in there somewhere! The window on the upper left is broken. Both of the windows are single pane glass. The way the window opening is made there is only about 1" of flat surface for the window. All the windows in the basement are like this! Eventually I'd like to have the window openings redone and some nice double panes installed, but for now I'll just replace both of these with some Plexiglass or polycarbonate. I think the mower kicked up a stone and sent it into the window. It will probably be two weeks before I can get it replaced.

Someone needs to tell Casey Jones that that mixed freight should not be on the passenger terminal siding, especially with cattle cars on!

The Milwaukee diesel is something I "inherited" from my son. I took him to a train show one year and he just HAD to have it. He's 18 now, and trains aren't cool anymore, so I repossessed it. I put a Digitrax decoder in it, and it runs very well. It has the road number 8. I don't recall exactly what diesel it is, though.

The conductor isn't real happy with the placement of the cattle cars. "This stinks" was his comment. Managements reply: "Too bad. So sad."

A few hours of work, and it's much better! I just knew there was a model railroad in there somewhere! The window on the upper left is broken. Both of the windows are single pane glass. The way the window opening is made there is only about 1" of flat surface for the window. All the windows in the basement are like this! Eventually I'd like to have the window openings redone and some nice double panes installed, but for now I'll just replace both of these with some Plexiglass or polycarbonate. I think the mower kicked up a stone and sent it into the window. It will probably be two weeks before I can get it replaced.

Someone needs to tell Casey Jones that that mixed freight should not be on the passenger terminal siding, especially with cattle cars on!

The Milwaukee diesel is something I "inherited" from my son. I took him to a train show one year and he just HAD to have it. He's 18 now, and trains aren't cool anymore, so I repossessed it. I put a Digitrax decoder in it, and it runs very well. It has the road number 8. I don't recall exactly what diesel it is, though.

The conductor isn't real happy with the placement of the cattle cars. "This stinks" was his comment. Managements reply: "Too bad. So sad."

goscrewyourselves

I'm the one

Have to laugh sorry, but don't feel too bad ...

This is what I am confronted with as well

This is what I am confronted with as well

flyboy2610

Loveably weird

It appears winter has finally finished! It was sunny and in the upper 80's today. I hung out down in the air conditioned man-cave and did a few things on the railroad, which has been too long neglected. (I know, bad me!)

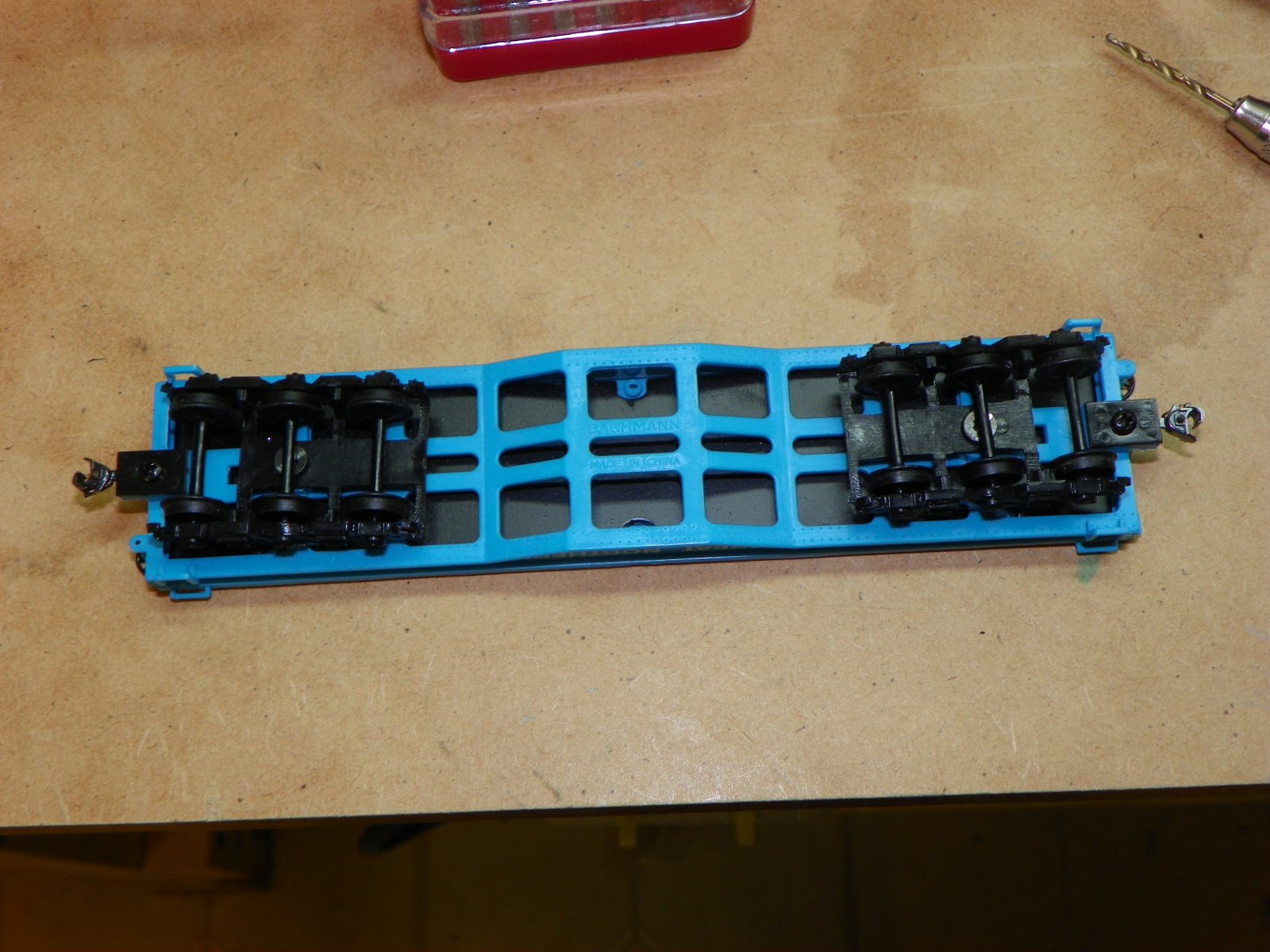

I replaced the couplers and wheels on three cars: a cattle car, a boxcar, and a flatbed. The flatbed was the most involved. It and the boxcar are train set Bachmann units, the cattle car is Athearn. The flatbed had posts in the center of the coupler pockets, which at one time I'm sure had tiny screws in them to hold the couplers on. The screws, coupler, and coupler box lids have long since vanished into the void of the space/time continuum! I drilled out the holes with my pin vise and a drill bit, tapped the holes, and installed #148 Kadee's with 1/4" long 2-56 pan head screws.

For the wheels I used Kadee smooth back 33" wheels. I discovered that the Kadee wheels were about .004" wider across the axle than the original Bachmann wheels. The Kadee's are also pointed on the ends, whiles the Bachmann's were more blunt. What all this meant was the Kadee's did not roll freely in the Bachmann trucks. I used a small hobby file and gave three strokes on each end of the Kadee axles, and used a sharp Exacto knife blade to clean out the holes in the trucks. Those wheels are now very free rolling.

Here is the finished flatbed. The pin vise and 2-56 tap are also shown. I got that screwdriver set at Menards. The bits are interchangeable. There are 4 each of Phillips, standard, and Torx bits. Also a slide on light ring I've never used. What I like about this is that inside the screwdriver barrel is a magnet. It holds the bits securely, and if the screw is steel it will hold it onto the bit. I really like this set!

A bottom view of the flatbed. This car has some weight to it!

The flatbed, the boxcar to it's left, and the cattle car behind it are the three I worked on today. They all roll very freely now! The conductor isn't very happy about the placement of those cattle cars, though!

The other end of the train. The locomotive is an Athearn unit. It's a Milwaukee Road SD45. I put a Digitrax decoder in it, and it runs and pulls very nicely. I bought it for my son at the Lincoln train show several years ago. I remember I paid $80 for it. But he's 18 now and trains are no longer cool, so I guess it's mine now! There's no danger of the train taking the death dive to the floor. The section of track it's on is electrically isolated until the lift out is in place and plugged in.

I replaced the couplers and wheels on three cars: a cattle car, a boxcar, and a flatbed. The flatbed was the most involved. It and the boxcar are train set Bachmann units, the cattle car is Athearn. The flatbed had posts in the center of the coupler pockets, which at one time I'm sure had tiny screws in them to hold the couplers on. The screws, coupler, and coupler box lids have long since vanished into the void of the space/time continuum! I drilled out the holes with my pin vise and a drill bit, tapped the holes, and installed #148 Kadee's with 1/4" long 2-56 pan head screws.

For the wheels I used Kadee smooth back 33" wheels. I discovered that the Kadee wheels were about .004" wider across the axle than the original Bachmann wheels. The Kadee's are also pointed on the ends, whiles the Bachmann's were more blunt. What all this meant was the Kadee's did not roll freely in the Bachmann trucks. I used a small hobby file and gave three strokes on each end of the Kadee axles, and used a sharp Exacto knife blade to clean out the holes in the trucks. Those wheels are now very free rolling.

Here is the finished flatbed. The pin vise and 2-56 tap are also shown. I got that screwdriver set at Menards. The bits are interchangeable. There are 4 each of Phillips, standard, and Torx bits. Also a slide on light ring I've never used. What I like about this is that inside the screwdriver barrel is a magnet. It holds the bits securely, and if the screw is steel it will hold it onto the bit. I really like this set!

A bottom view of the flatbed. This car has some weight to it!

The flatbed, the boxcar to it's left, and the cattle car behind it are the three I worked on today. They all roll very freely now! The conductor isn't very happy about the placement of those cattle cars, though!

The other end of the train. The locomotive is an Athearn unit. It's a Milwaukee Road SD45. I put a Digitrax decoder in it, and it runs and pulls very nicely. I bought it for my son at the Lincoln train show several years ago. I remember I paid $80 for it. But he's 18 now and trains are no longer cool, so I guess it's mine now! There's no danger of the train taking the death dive to the floor. The section of track it's on is electrically isolated until the lift out is in place and plugged in.

flyboy2610

Loveably weird

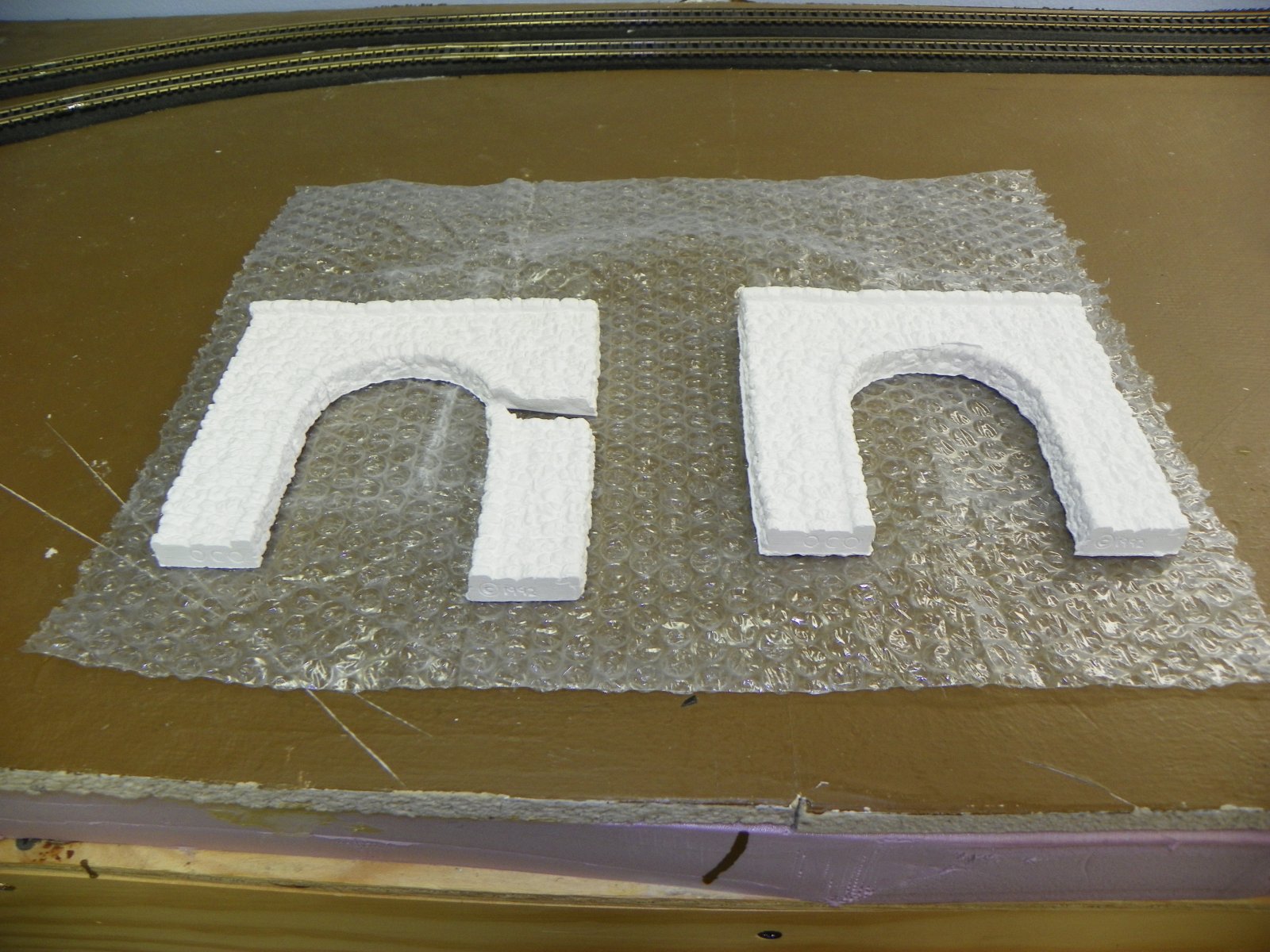

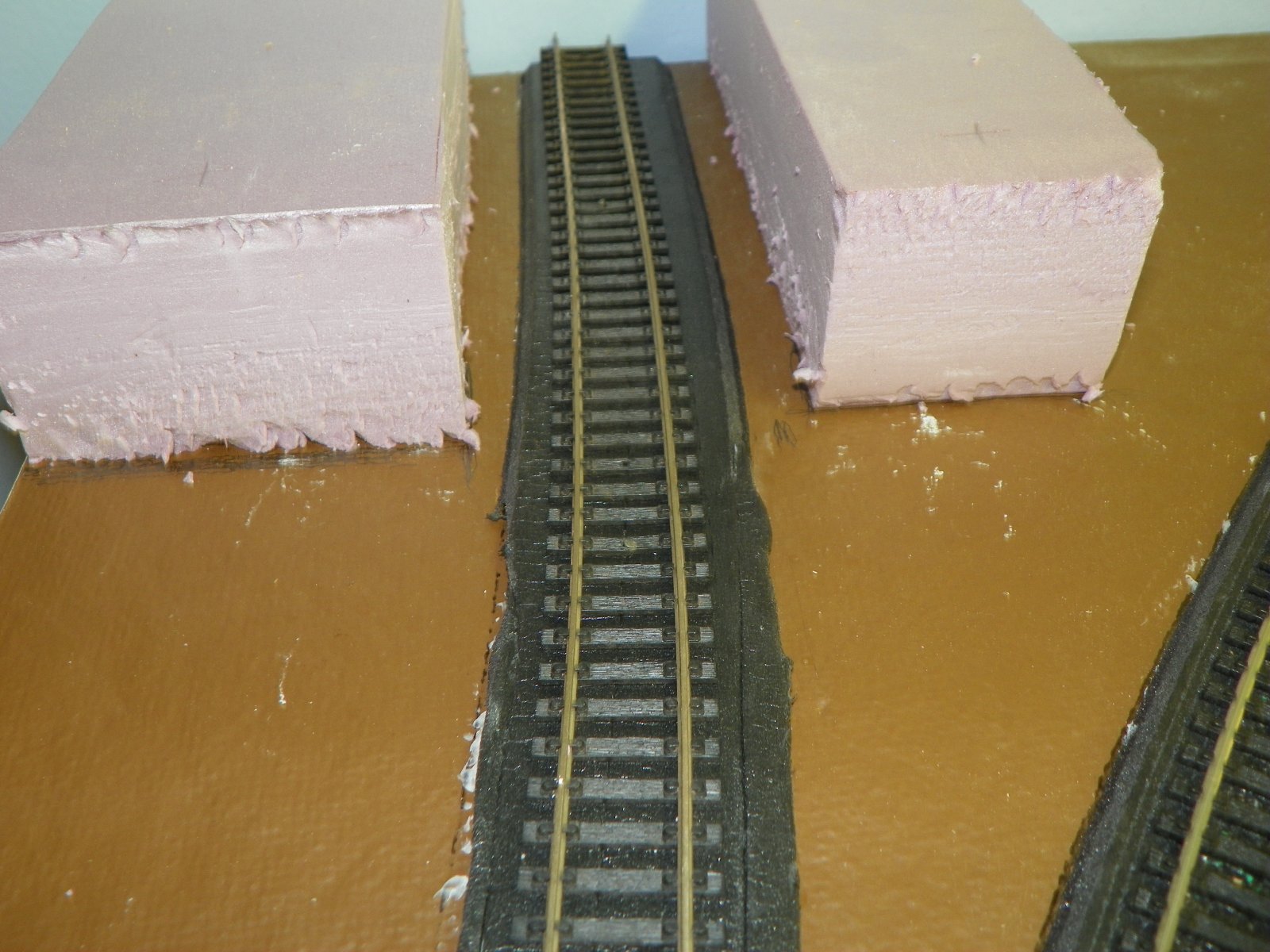

At the train show here in Lincoln 3 months ago I bought a pair of Woodland Scenics Random Stone tunnel portals. On inspecting them when I got home, I discovered that one of them had broken into two pieces. For trains show items some dings and boo-boos are not uncommon, considering how many times those items are packed, moved, and unpacked.

Some Elmer's Glue-All and a clamp is taking care of that problem. I've read that plain ordinary white glue is the best thing to use to repair plaster because it seeps into the pores and creates a very strong bond.

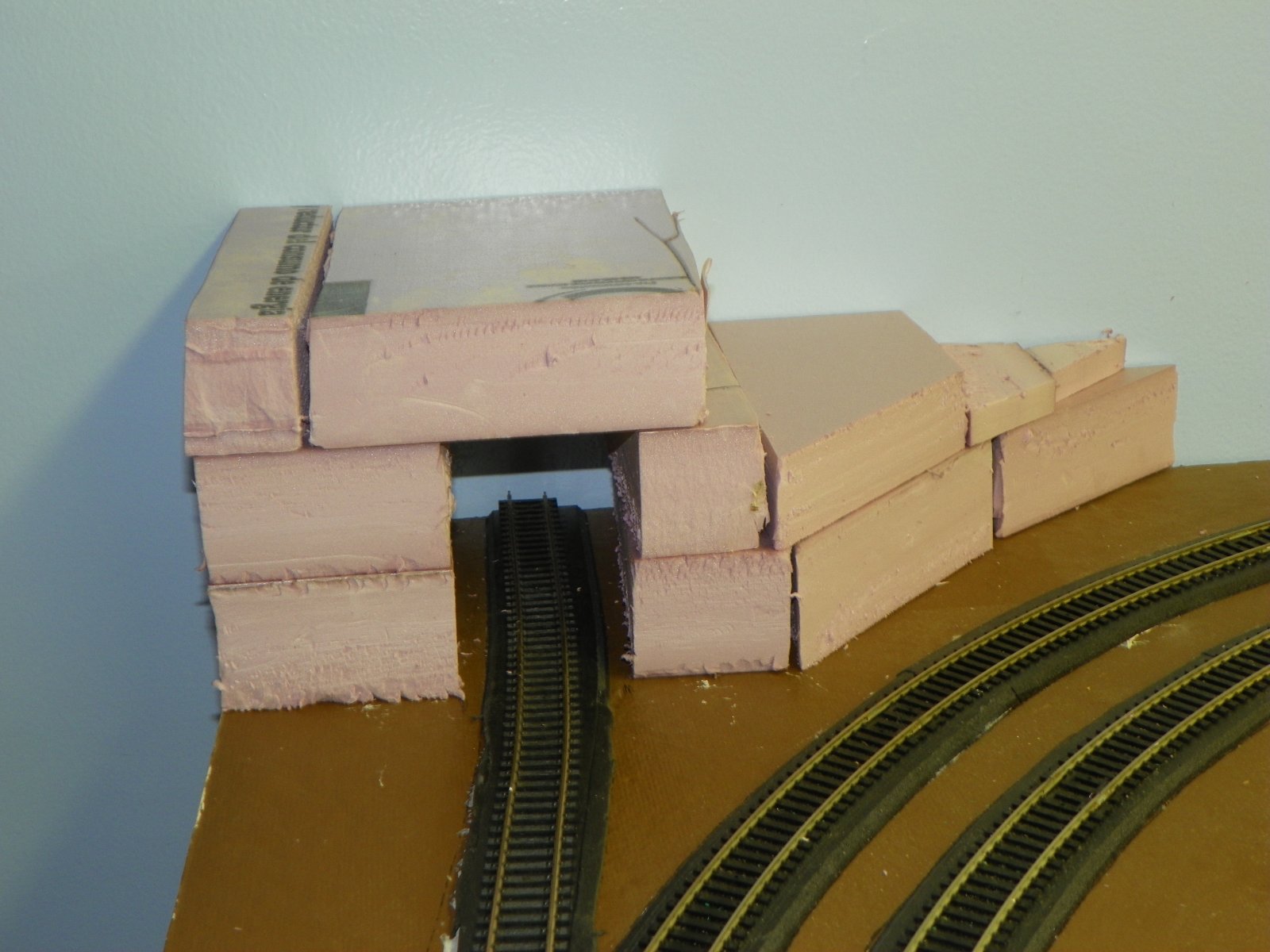

On the north end of my layout, there is a track going to the wall on one side and coming 'out' of the wall on the other. I wanted to do something to dress those up a bit. My original thought was to glue a portal to the wall over each track. If you look closely at the track coming off of the turnout, you will see that both rails are gapped. No chance of doing a Gomez Addam's into the wall!

But that would still look a bit tacky, so I'm going to put a hill on each side with the tunnel portal on the face of the hill. You may say "There are no railroad tunnels in Nebraska. Actually....... there is one.

From https://en.wikipedia.org/wiki/Belmont_Tunnel_(Nebraska)

"The Belmont Tunnel is a 698-foot (213 m) long railway tunnel near the ghost town of Belmont about halfway between Crawford and Marsland, Nebraska, in western Dawes County.[1][2] It was built by the Chicago, Burlington and Quincy Railroad in 1888-1889 and was used regularly until it was bypassed in 1982. It is the only railway tunnel ever constructed in Nebraska.[3] "

So I can have one, too! (Actually, two. One on each side.)

I'm going to make the hills out of foam and cover them with plaster cloth. I want them to be stationary, but be able to remove them if I have to. What I plan to do is to drill down 4 inches making two holes on each side of the tunnel through the foam and into the table top. I'll make the holes 1/2" diameter. I will then glue 4" wooden dowels into the foam only. This will positively locate the hills, keep them in place, but permit removal in needed.

The tunnel portion of the hill is 5 pieces of 2" thick foam, 2 on each side and one across the top. There will be some additional foam on the side to give a slope to the hill. I can't go too far, because the passenger station will be next to the hill. It will be a building flat maybe 1/2' deep.

Here's a pic with the portal in place. The socket is there to keep the portal upright.

I think this is going to look pretty good.

Some Elmer's Glue-All and a clamp is taking care of that problem. I've read that plain ordinary white glue is the best thing to use to repair plaster because it seeps into the pores and creates a very strong bond.

On the north end of my layout, there is a track going to the wall on one side and coming 'out' of the wall on the other. I wanted to do something to dress those up a bit. My original thought was to glue a portal to the wall over each track. If you look closely at the track coming off of the turnout, you will see that both rails are gapped. No chance of doing a Gomez Addam's into the wall!

But that would still look a bit tacky, so I'm going to put a hill on each side with the tunnel portal on the face of the hill. You may say "There are no railroad tunnels in Nebraska. Actually....... there is one.

From https://en.wikipedia.org/wiki/Belmont_Tunnel_(Nebraska)

"The Belmont Tunnel is a 698-foot (213 m) long railway tunnel near the ghost town of Belmont about halfway between Crawford and Marsland, Nebraska, in western Dawes County.[1][2] It was built by the Chicago, Burlington and Quincy Railroad in 1888-1889 and was used regularly until it was bypassed in 1982. It is the only railway tunnel ever constructed in Nebraska.[3] "

So I can have one, too! (Actually, two. One on each side.)

I'm going to make the hills out of foam and cover them with plaster cloth. I want them to be stationary, but be able to remove them if I have to. What I plan to do is to drill down 4 inches making two holes on each side of the tunnel through the foam and into the table top. I'll make the holes 1/2" diameter. I will then glue 4" wooden dowels into the foam only. This will positively locate the hills, keep them in place, but permit removal in needed.

The tunnel portion of the hill is 5 pieces of 2" thick foam, 2 on each side and one across the top. There will be some additional foam on the side to give a slope to the hill. I can't go too far, because the passenger station will be next to the hill. It will be a building flat maybe 1/2' deep.

Here's a pic with the portal in place. The socket is there to keep the portal upright.

I think this is going to look pretty good.

flyboy2610

Loveably weird

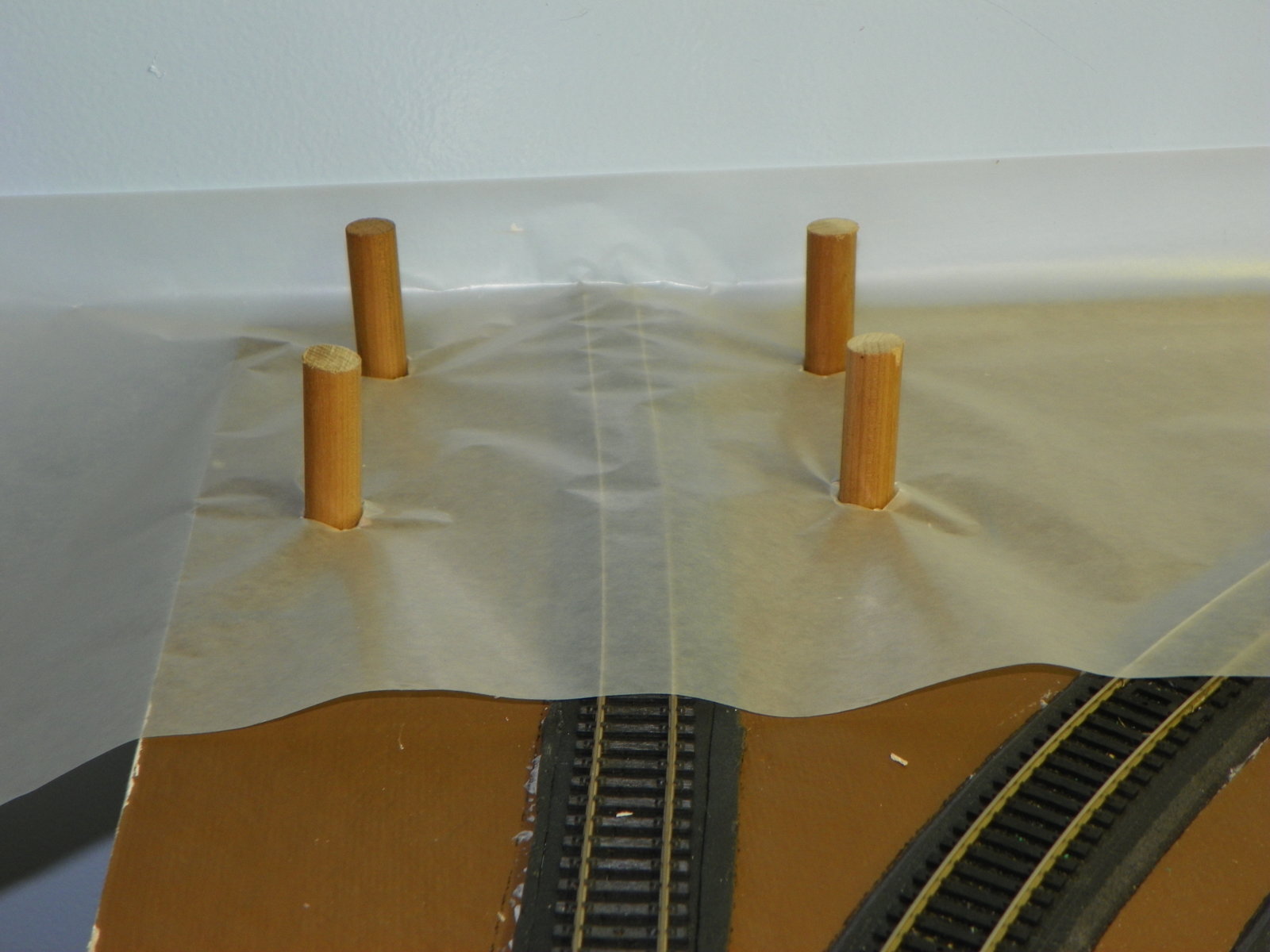

Well, there's been a change of plans: the locating holes are going to be 5/8" instead of 1/2". Why? I don't have a 1/2" dowel, but I do have a 5/8" dowel.

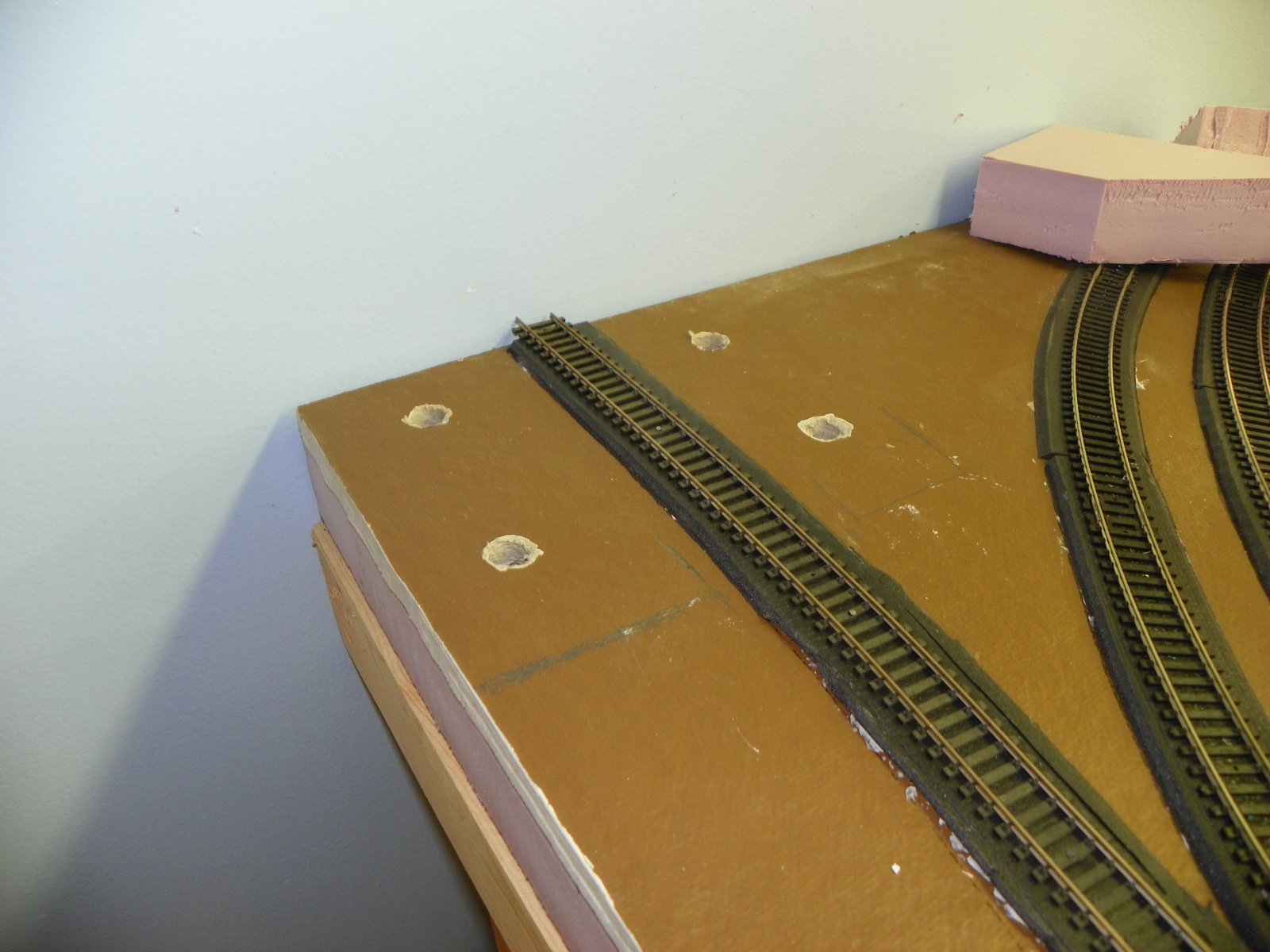

The first thing I did was mark around the edges of the two foam blocks on either side of the track. I also marked the front end and where the two holes in each block would go. The location of the holes isn't critical, but I wanted them located away from any framing members.

I drilled the holes through the blocks on my drill press. With the drill inserted all the way into the chuck and the table as low as it would go, there was JUST enough room for the block to fit under the drill, although it did leave a scratch on the block! The painters tape indicates the depth of the drill through the table top. It will go through the Homasote and 2" foam, but not through the plywood deck.

Once the holes were made in the foam blocks (yes, it did make a mess but the hand held vac cleaned it up quickly) I put the drill bit into my cordless drill, held the blocks firmly in place, and drilled the pilot holes into the Homasote.

The blocks were then removed and the table drilled to the correct depth. I used an Exacto knife to clean up the top of the holes a bit. I used the big shop vac to get all the debris out of the holes.

I used a piece of 3/8" dowel to get the proper length of the alignment dowels. The 5/8" dowel was too long to fit under the ceiling overhang.

I cut the dowels to length using a miter box and hand saw. I intentionally cut them a bit short so they would not interfere with the foam blocks above them. I also wallowed out the holes in the Homasote just a little bit because the dowels fit VERY tightly into the holes! I don't want to destroy my hill trying to remove it!

I was going to use Titebond to glue the dowels into the foam blocks (they will not be glued into the tabletop) but after removing and replacing the foam blocks a few times, the holes in the blocks were a little wallowed out, so I decided to use Liquid Nails for Projects instead. It was at this point I discovered I'm out of it! It will probably be next weekend before I can get some. I think while I'm at Menards I'll pick up a quart or two of Glidden Gripper primer. It won the award for "Best Glue for Foam":

The first thing I did was mark around the edges of the two foam blocks on either side of the track. I also marked the front end and where the two holes in each block would go. The location of the holes isn't critical, but I wanted them located away from any framing members.

I drilled the holes through the blocks on my drill press. With the drill inserted all the way into the chuck and the table as low as it would go, there was JUST enough room for the block to fit under the drill, although it did leave a scratch on the block! The painters tape indicates the depth of the drill through the table top. It will go through the Homasote and 2" foam, but not through the plywood deck.

Once the holes were made in the foam blocks (yes, it did make a mess but the hand held vac cleaned it up quickly) I put the drill bit into my cordless drill, held the blocks firmly in place, and drilled the pilot holes into the Homasote.

The blocks were then removed and the table drilled to the correct depth. I used an Exacto knife to clean up the top of the holes a bit. I used the big shop vac to get all the debris out of the holes.

I used a piece of 3/8" dowel to get the proper length of the alignment dowels. The 5/8" dowel was too long to fit under the ceiling overhang.

I cut the dowels to length using a miter box and hand saw. I intentionally cut them a bit short so they would not interfere with the foam blocks above them. I also wallowed out the holes in the Homasote just a little bit because the dowels fit VERY tightly into the holes! I don't want to destroy my hill trying to remove it!

I was going to use Titebond to glue the dowels into the foam blocks (they will not be glued into the tabletop) but after removing and replacing the foam blocks a few times, the holes in the blocks were a little wallowed out, so I decided to use Liquid Nails for Projects instead. It was at this point I discovered I'm out of it! It will probably be next weekend before I can get some. I think while I'm at Menards I'll pick up a quart or two of Glidden Gripper primer. It won the award for "Best Glue for Foam":

flyboy2610

Loveably weird

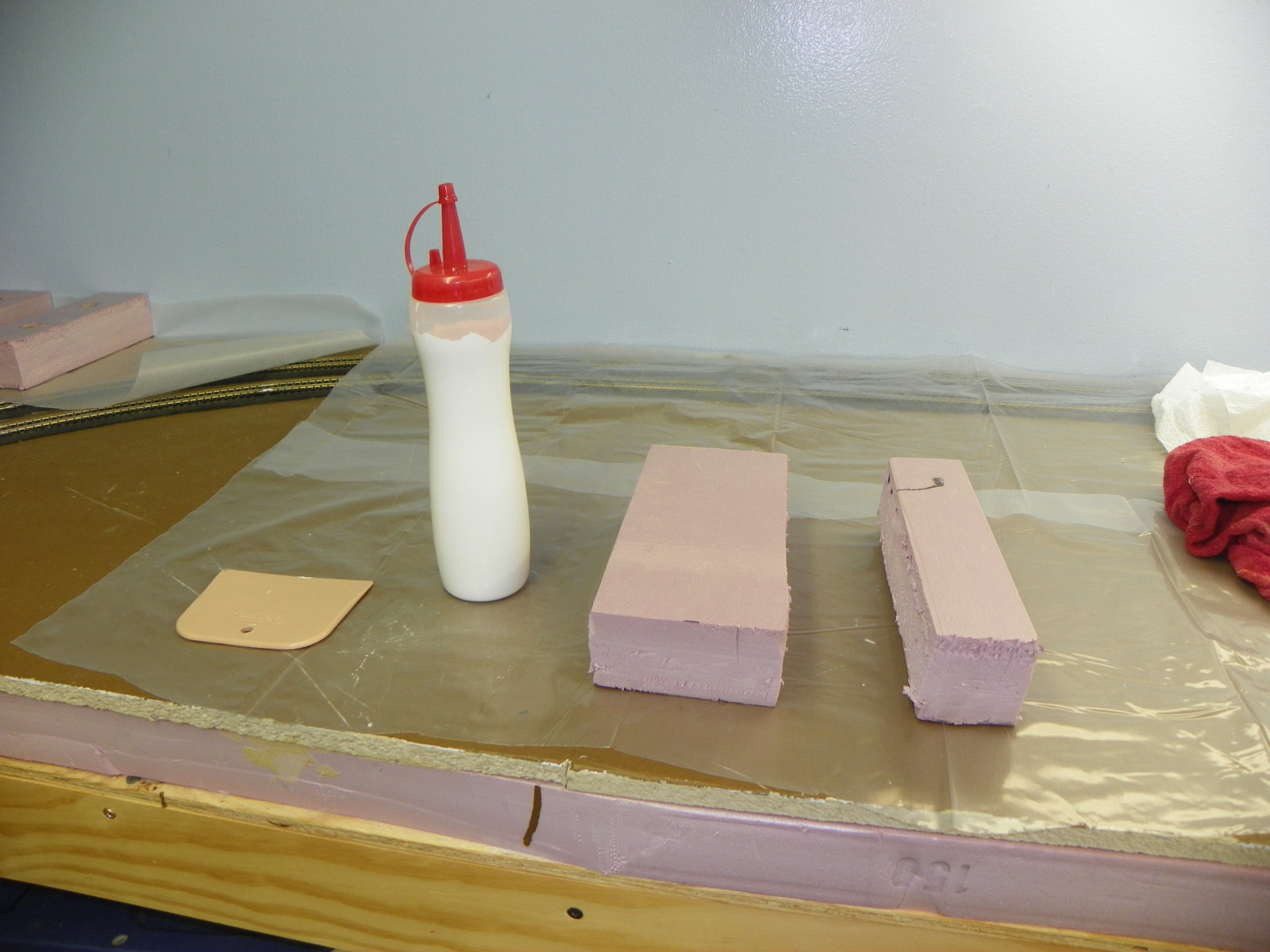

I bought some Glidden Gripper and Liquid Nails for projects at Home Depot.

I also bought a couple of inexpensive condiment dispensing bottles. I'm going to use one for Gripper, and one for diluted matte medium. I used a Bondo spreader to spread out the Gripper.

I put down some plastic on the layout and some waxed paper under the hill area. This way I won't make a mess on the layout, and I won't accidentally glue the hill to the tabletop.

It only takes a thin coat of Gripper to glue the pieces together. I read a couple of posts on different forums where people have used a thin coat, pressed the pieces together and moved them a round a bit to get good coverage, then separated them and let them tack up for about 15 minutes. They reassembled them, weighted them down, and let them sit for 48 hours. Once dried, nothing could break the joint.

So that's what I did.

Now comes the hard part: waiting for 48 hours! I made sure the front faces were even, so that the tunnel portal would have good glue contact.

I also bought a couple of inexpensive condiment dispensing bottles. I'm going to use one for Gripper, and one for diluted matte medium. I used a Bondo spreader to spread out the Gripper.

I put down some plastic on the layout and some waxed paper under the hill area. This way I won't make a mess on the layout, and I won't accidentally glue the hill to the tabletop.

It only takes a thin coat of Gripper to glue the pieces together. I read a couple of posts on different forums where people have used a thin coat, pressed the pieces together and moved them a round a bit to get good coverage, then separated them and let them tack up for about 15 minutes. They reassembled them, weighted them down, and let them sit for 48 hours. Once dried, nothing could break the joint.

So that's what I did.

Now comes the hard part: waiting for 48 hours! I made sure the front faces were even, so that the tunnel portal would have good glue contact.

goscrewyourselves

I'm the one

I also use Liquid Nails Projects for my road bed and track, it is good stuff and holds quickly. Have not heard of the "Gripper" though. It might be better for the roadbed so long as your patient.

flyboy2610

Loveably weird

I don't know how well Glidden Gripper would work for track and roadbed. I use DAP Alex Plus siliconized latex caulk for that. Glidden Gripper is a white primer/sealer paint, but people say it works great for using on foamboard. I plan on gluing the layers of the hill together with it. I bought the Liquid Nails for projects to glue the dowels into the base of the hill to locate it and hold it in place, but now that I think about it, I may just leave them unglued in their holes. Nothing would be going anywhere even that way.