flyboy2610

Loveably weird

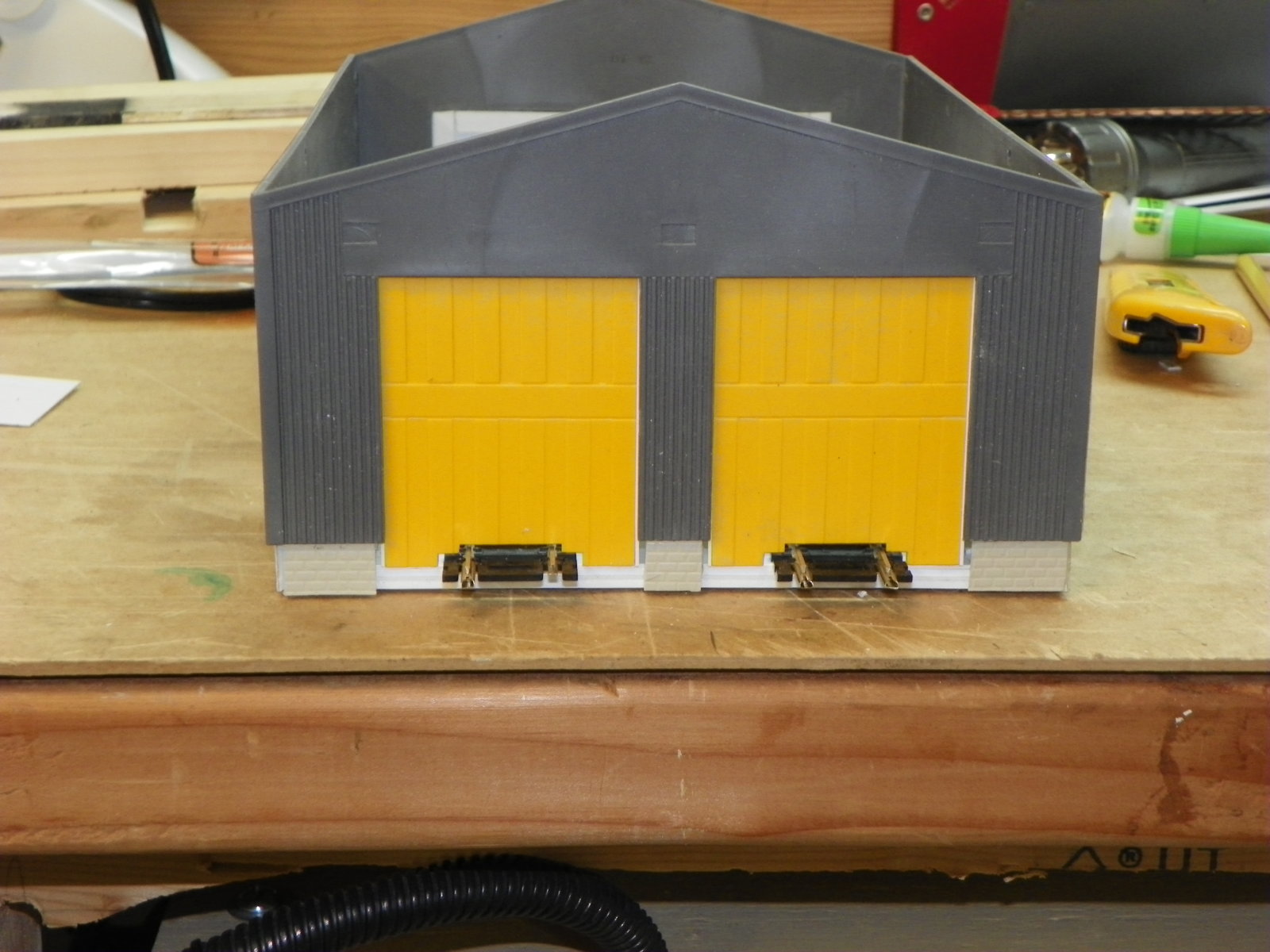

Work continues on the RustEze Medicated Bumper Ointment shipping/receiving building.

I have drawn the lines on the upper part of the floor. I have positioned a couple of boxcars on the floor to give an idea of how they will fit in the building.

The right side of the floor will be notched to fit around the door I beams.

I am using some Plastruct 1/2" I beams to bring the floor up to the level of the boxcar doors.

Here I have glued the I-beams in place to support the floor.

Holy kumquats, Batman! It actually fit correctly on the first try! That never happens. At least to me. But the floor fits correctly. I will glue some styrene around the bottom edges to conceal the gap.

Here is a pic of a couple of boxcars inside the building.

And with the doors in place. The doors will be cut and glued in the open position.

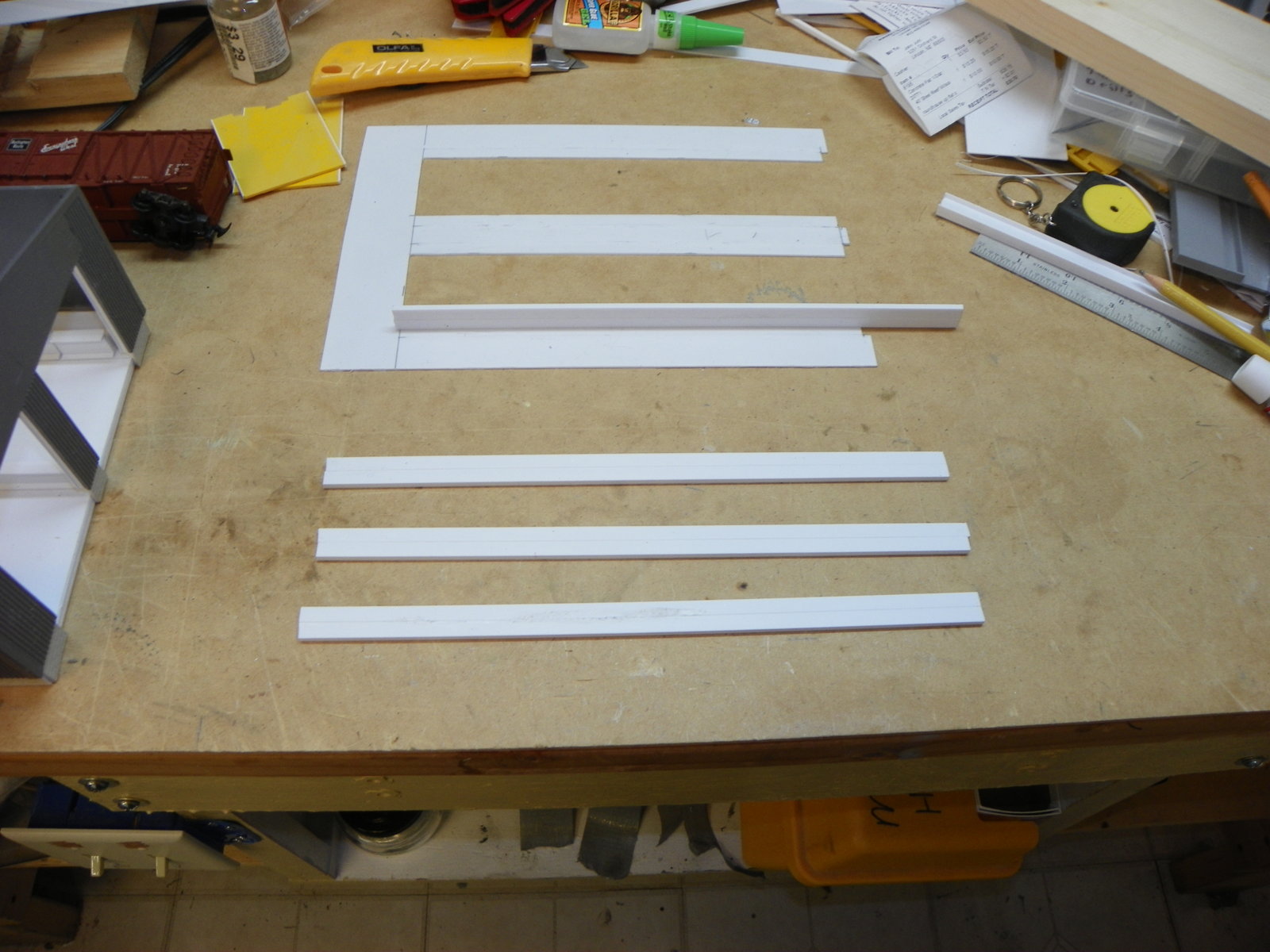

I glued some Plastruct .125 x .250 strips together to make some .125 x .500 strips. these will go under the bottom edge of the floor to seal the gap and provide support for the edge of the floor. I have placed on the floor so you can see how they'll be positioned.

I have decided to relocate the entrance doors to the back sides of the building. In their current position, people entering the facility would walk right into the area where the forklifts would be entering and exiting the boxcars. Management does not like that idea. After the floor is installed, I'll glue some styrene sheet along the inner walls to give them a finished look and hide the mold marks. Then I'll patch the outer wall and foundation.

I had a thought earlier: Why am I putting so much time and effort into something for which there's not even a prototype? The answer: I don't know. But I'm having fun doing it, and that's really all that matters!

I have drawn the lines on the upper part of the floor. I have positioned a couple of boxcars on the floor to give an idea of how they will fit in the building.

The right side of the floor will be notched to fit around the door I beams.

I am using some Plastruct 1/2" I beams to bring the floor up to the level of the boxcar doors.

Here I have glued the I-beams in place to support the floor.

Holy kumquats, Batman! It actually fit correctly on the first try! That never happens. At least to me. But the floor fits correctly. I will glue some styrene around the bottom edges to conceal the gap.

Here is a pic of a couple of boxcars inside the building.

And with the doors in place. The doors will be cut and glued in the open position.

I glued some Plastruct .125 x .250 strips together to make some .125 x .500 strips. these will go under the bottom edge of the floor to seal the gap and provide support for the edge of the floor. I have placed on the floor so you can see how they'll be positioned.

I have decided to relocate the entrance doors to the back sides of the building. In their current position, people entering the facility would walk right into the area where the forklifts would be entering and exiting the boxcars. Management does not like that idea. After the floor is installed, I'll glue some styrene sheet along the inner walls to give them a finished look and hide the mold marks. Then I'll patch the outer wall and foundation.

I had a thought earlier: Why am I putting so much time and effort into something for which there's not even a prototype? The answer: I don't know. But I'm having fun doing it, and that's really all that matters!