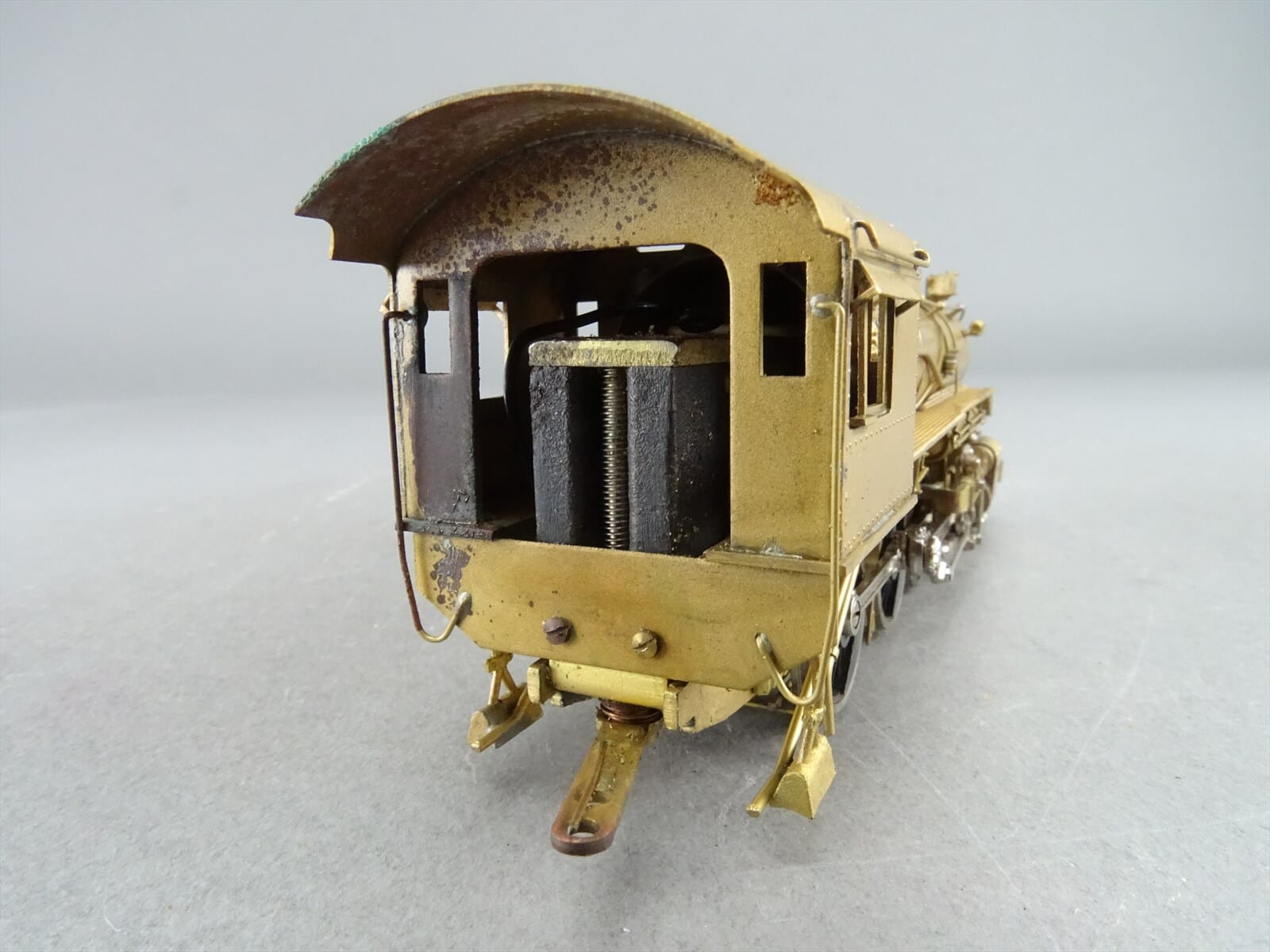

Time to paint that ten wheeler guys! Well...sort of. I'm going to do a little bait & switch on you. It's still going to be a Ten Wheeler, just not that little one. I found another bargain over at Brass Trains. There are a few left in case you're curious! There was a SP T-31 4-6-0 for sale with "running issues". Now this can mean just about anything. It can be something as simple as a tender truck reversed, or a broken neoprene coupling between the motor & gearbox, or it can be something more fun. You pays your money and you takes your chances. I wanted it, it's a good looking model. Nice ones usually start in the high two hundreds to mid threes. They wanted $185. I though it over for a couple of days and pulled the trigger. It showed up today and, well, you know, I had to find out what "running issues" meant. Not a sound when power was applied, so off came the boiler. Wiring was good, so off came the motor. It was frozen solid. No big deal, its an open framer and is going away no matter what anyhow. A fresh motor temporarily mounted, and still no movement. Gearbox comes off. Gearbox frozen solid! I happen to have a stash of KTM gearboxes, the factory replacement for what's in this model. Don't ever let anyone tell you it doesn't pay to be a pack rat! But then you all know that, don't you? Of course since I'm a cheap packrat, I didn't want to chuck this gearbox without attempting a fix. I opened it up, and it was totally dry. Not even that dried up old grease you usually see in these. The parts bag was in the box, still sealed. The boiler weight was still sealed in its factory bag with the screw, so this thing had never been run, or at least it was test run only. It has spent most if its existence in the box, hence these problems. I ended up soaking it in some oil, prying the stuck bearing off the shaft and polishing it, and the worm shaft. That did the trick. The mechanism is very smooth, no binds, and the frame design will make re-motoring a snap. Bottom line is I already have this thing stripped down far enough that it doesn't make sense to put it back together, so I'm going to proceed from here. I have a missing tender step (that I knew about) so I'll have to make one, and we'll do the usual added details, bell rope, whistle rod, lagging clamps, and anything else I come across. Have a look:

Last edited: