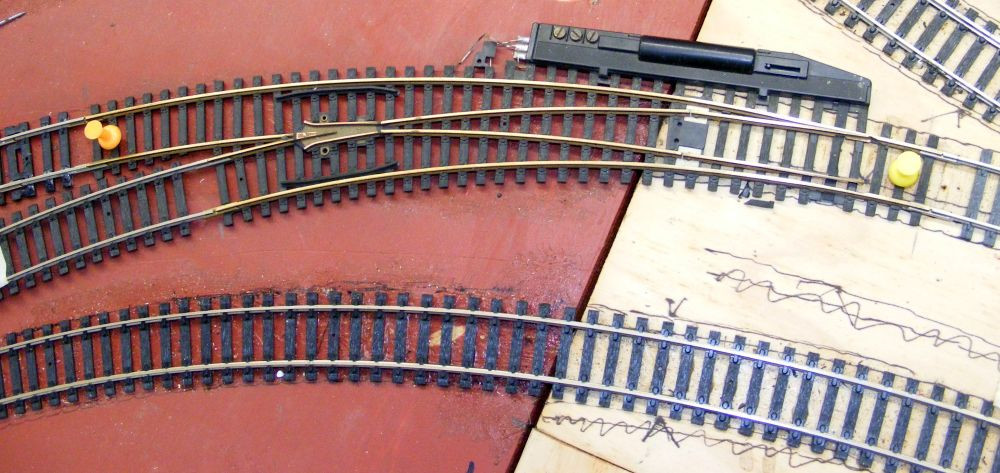

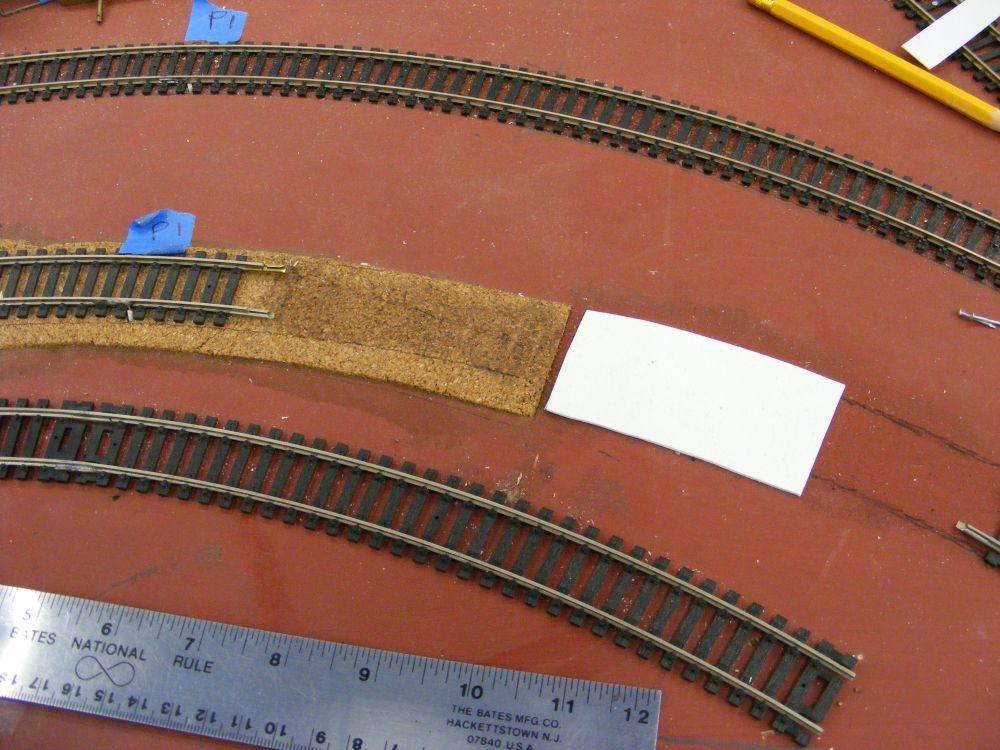

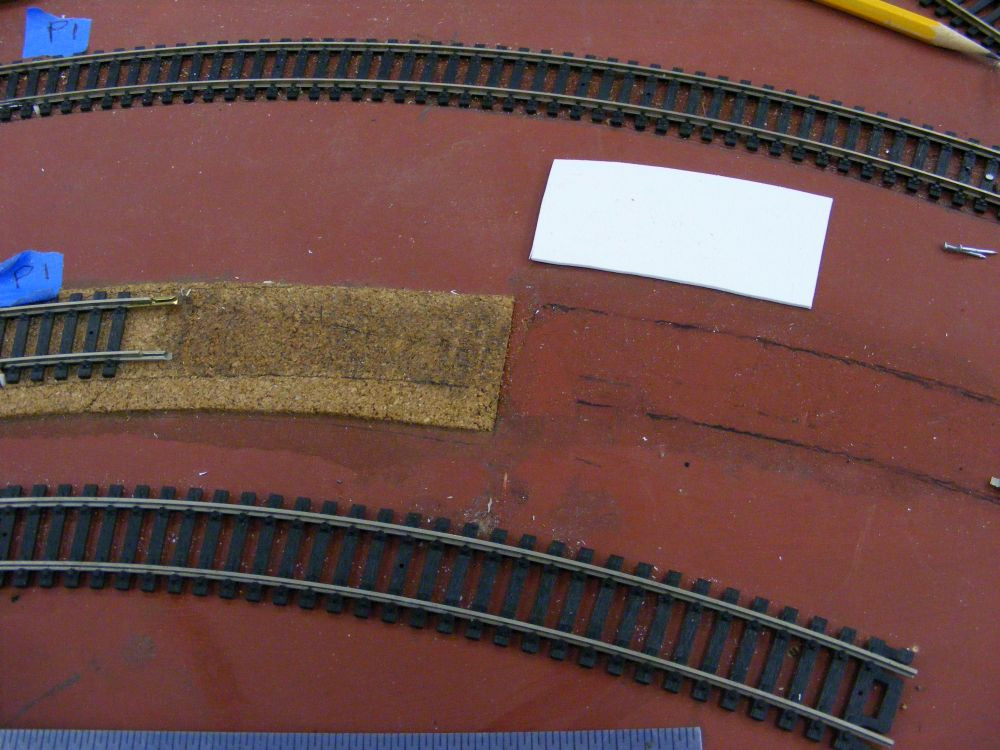

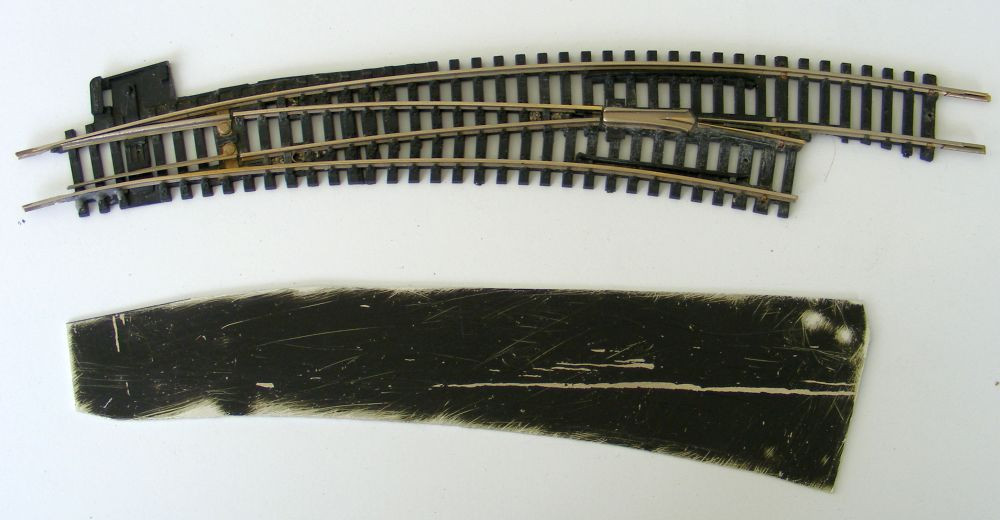

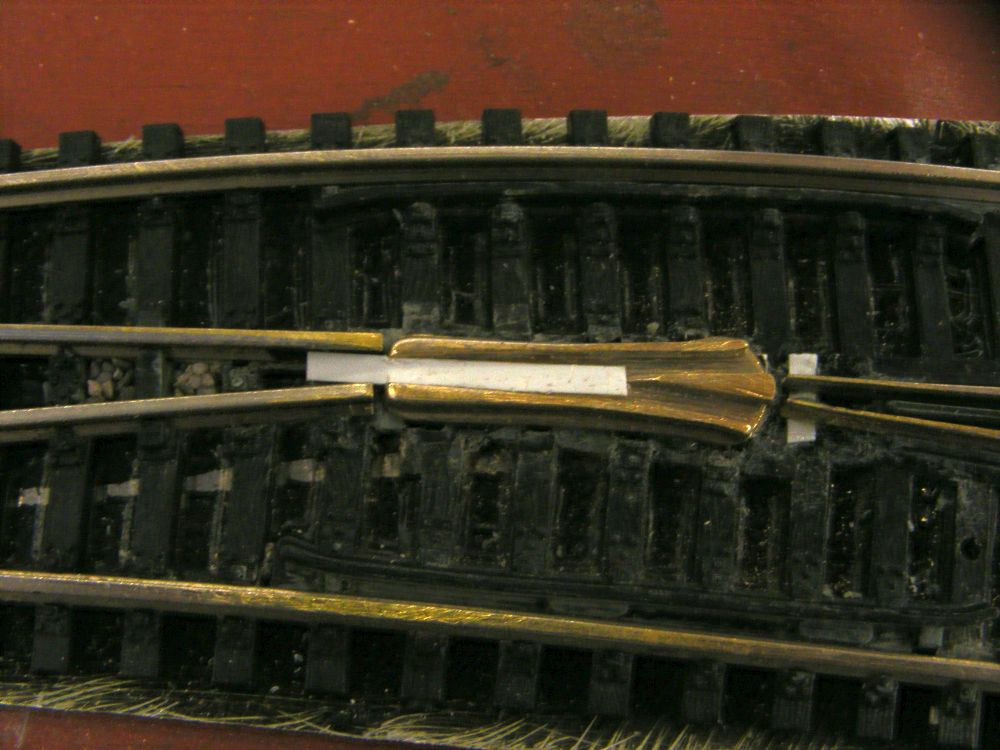

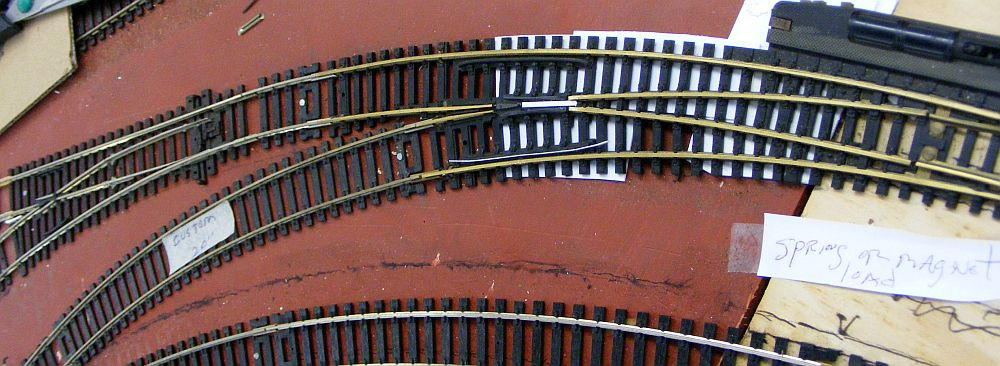

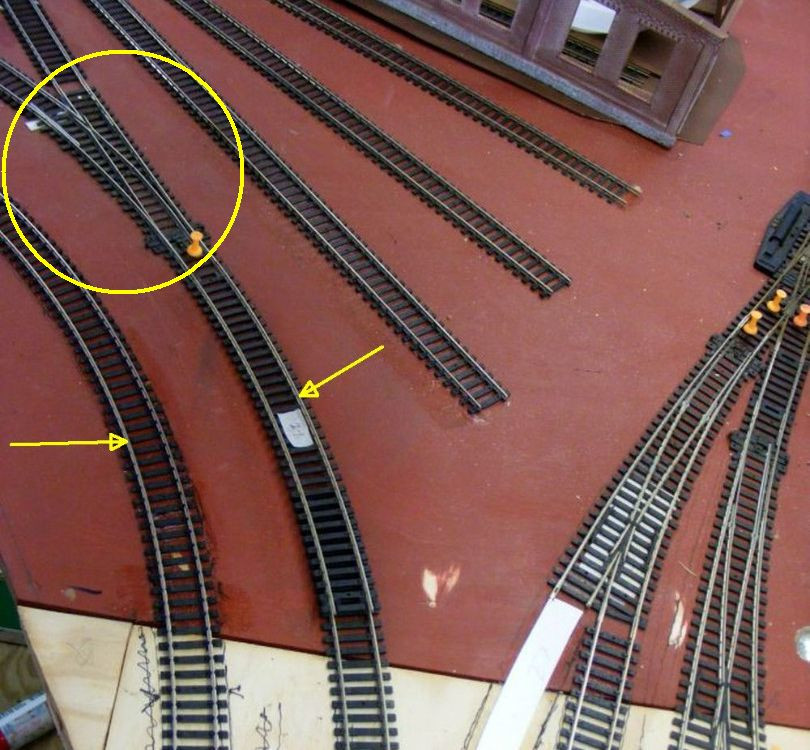

There was a reason I kept looking back at this area of track. Originally I had some trouble SMOOTHLY inserting this small radius Peco turnout into the constantly curving 24" curve,..

It was not as smooth (no kinks) as I had wanted. I had actually cut the diverging tracks off slightly to try and get a smoother curve.

I then became aware that the' constant 24" radius' of that stock Peco turnout was in fact not absolutely constant, nor was it all 24".

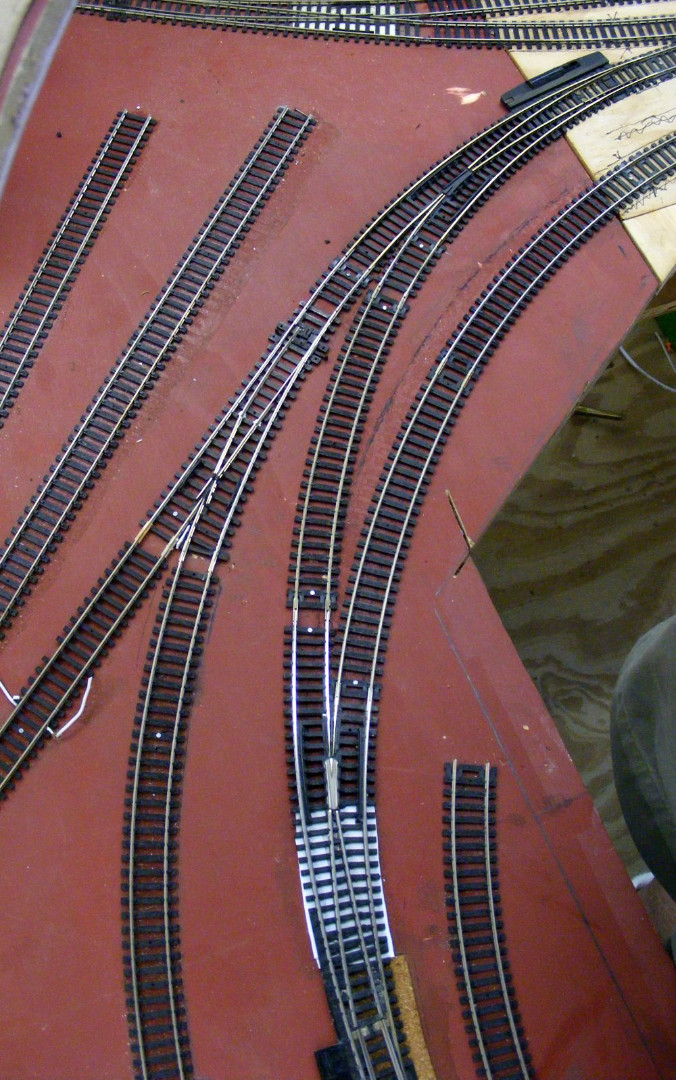

This keep wearing on my mind as it was so important for my numerous steam engines to get back to the turntable. I vowed I was going to try and fix it.

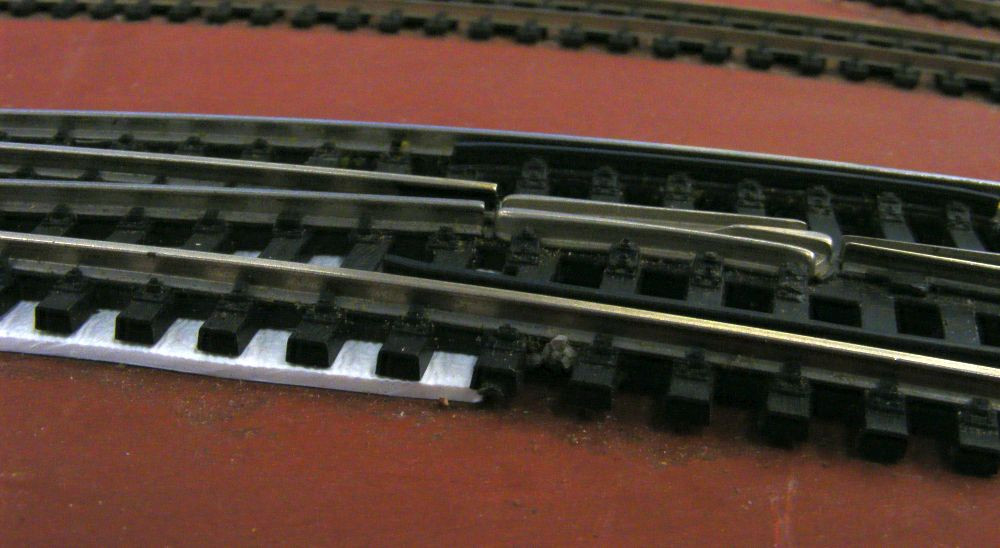

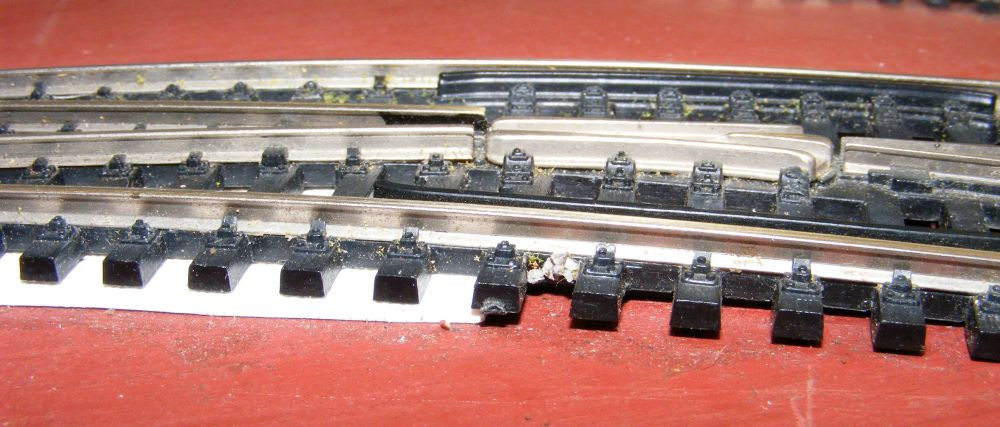

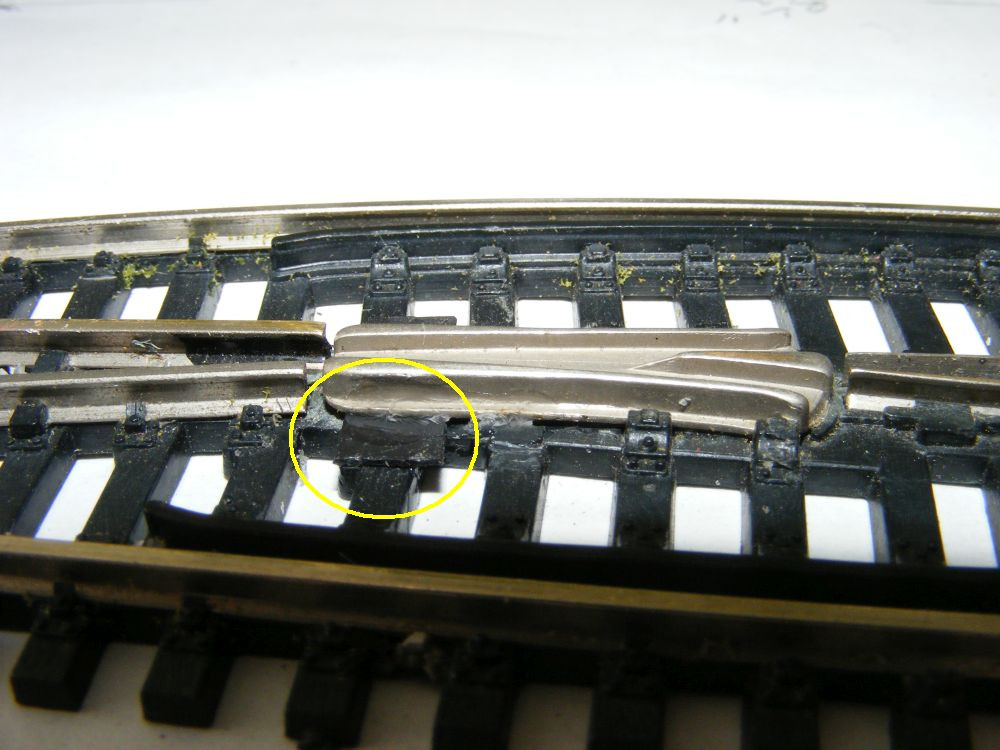

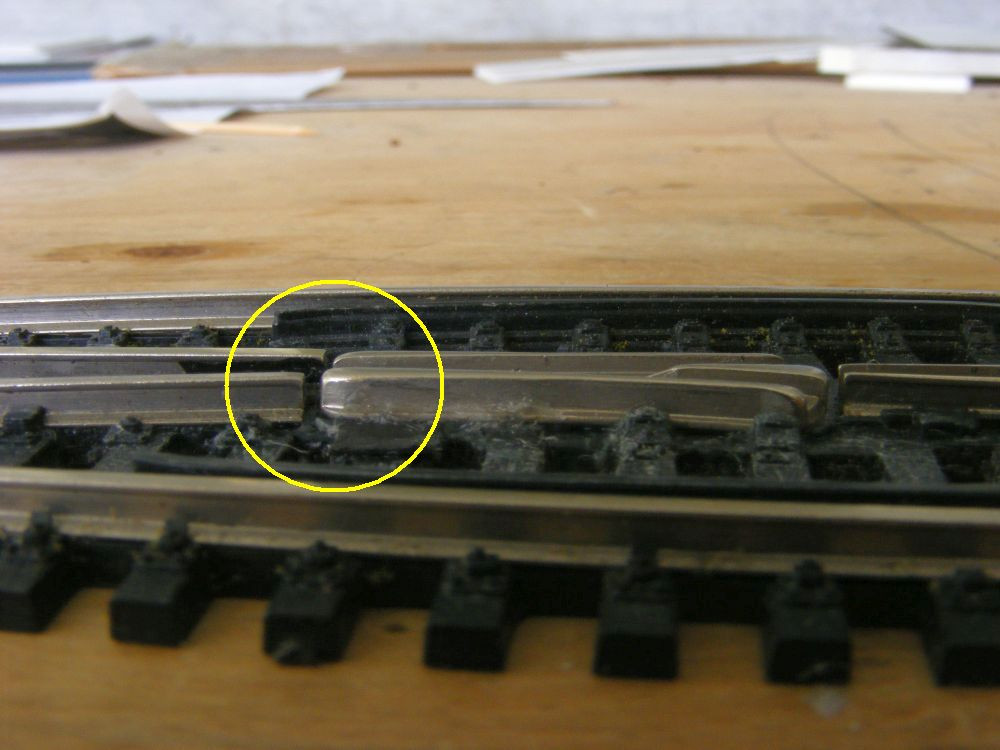

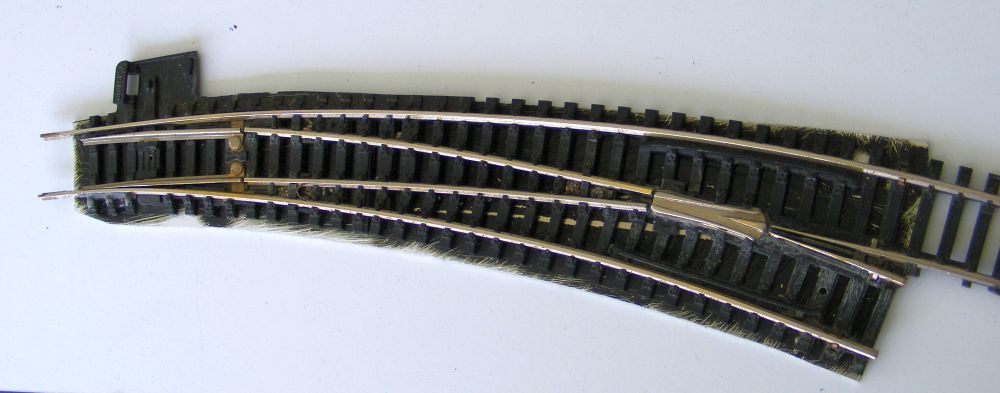

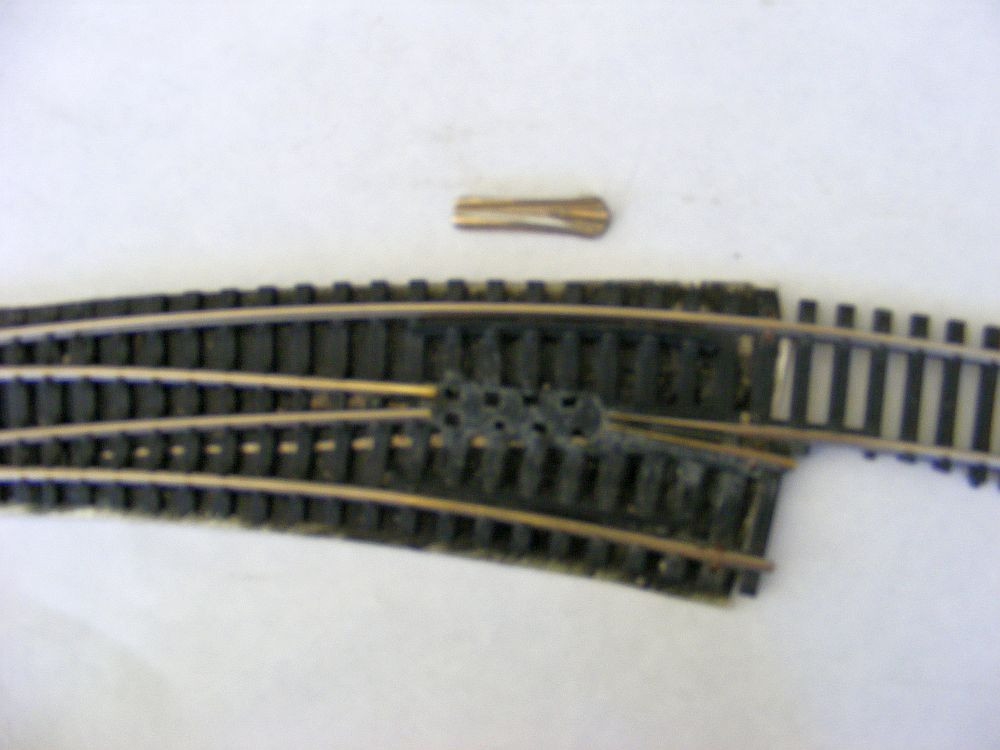

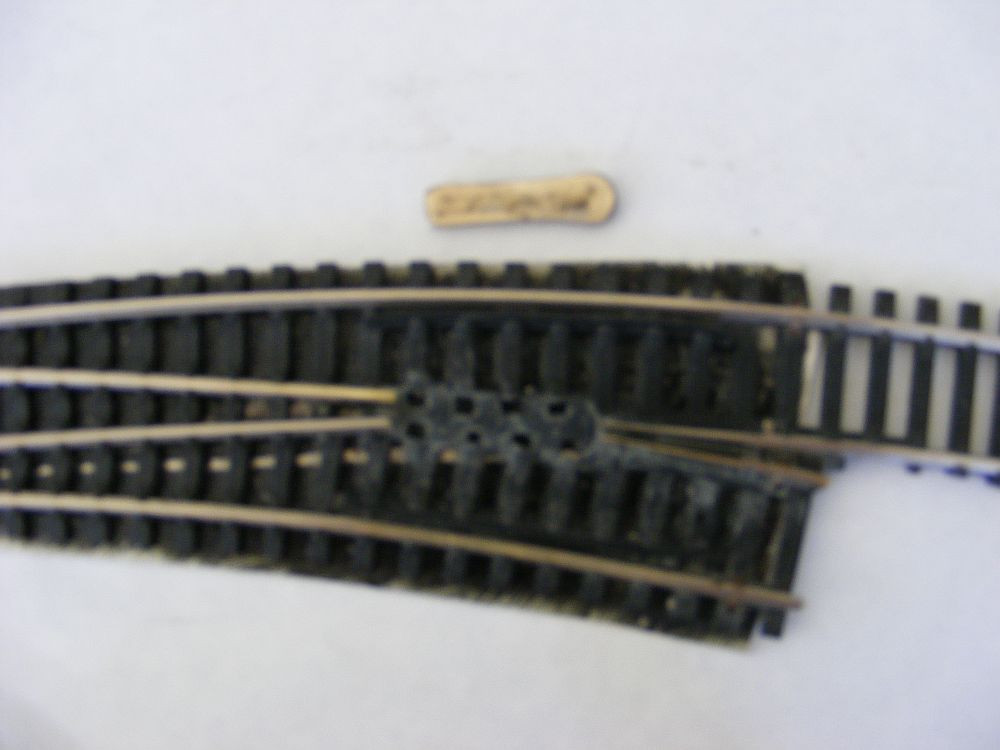

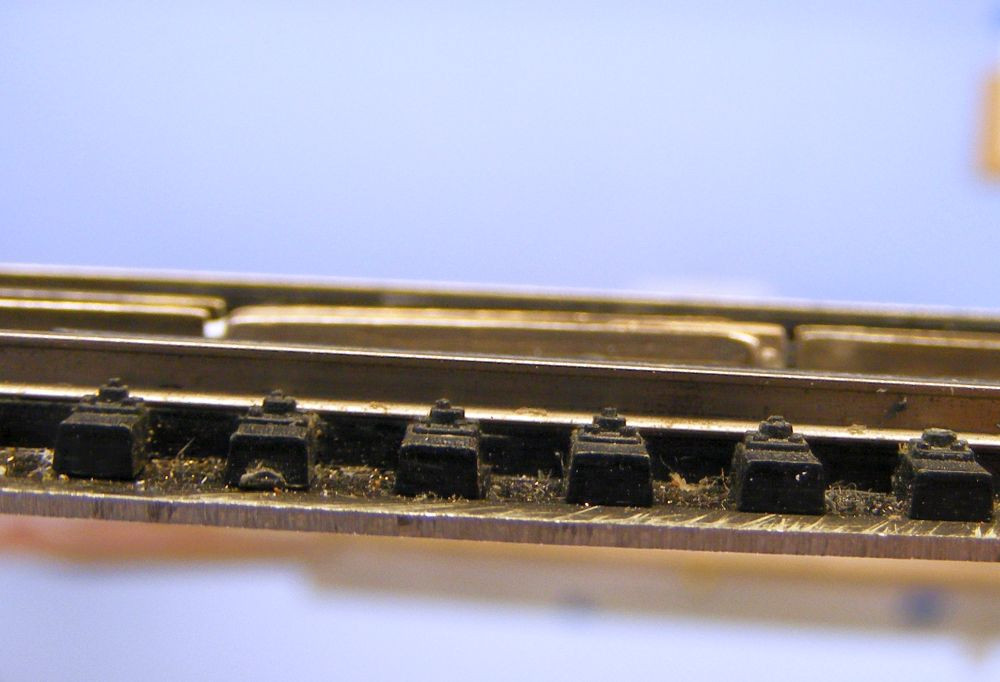

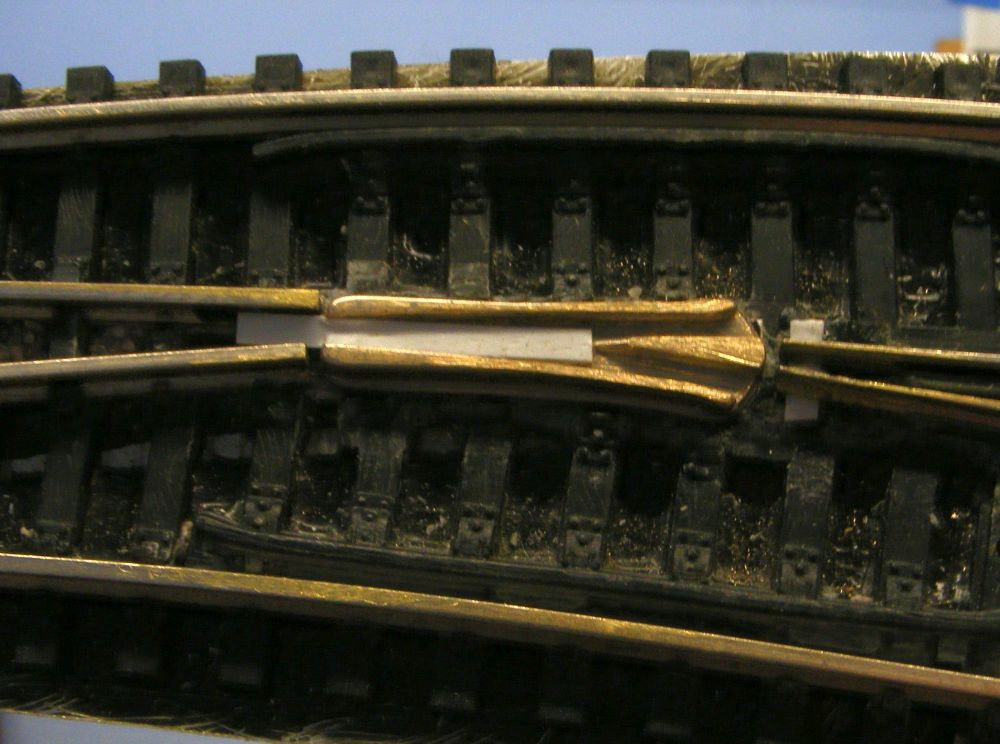

My first thought was to replace it with a Peco short Y that also is advertised as 24"radius also. But that would create an an S turn in that trackage. No, I was going to have to see if I could massage a conventional sm Peco to work. I ended up taking a brand new sm-r Peco and cutting a slot in the two ties between the V area between the 2 tracks exiting the frog,..

I then inserted a piece of plastic into that cut slot to help with maintaining that spread of the diverging tracks. Now my new modified Peco snall-r looks smoother in its overall 24" curve.

*****************

PS: It was this turnout problem that kept me looking back at this area of track, AND the reason I took a new look at providing a new connection between the 2 curves utilizing double curves,.....to be continued.

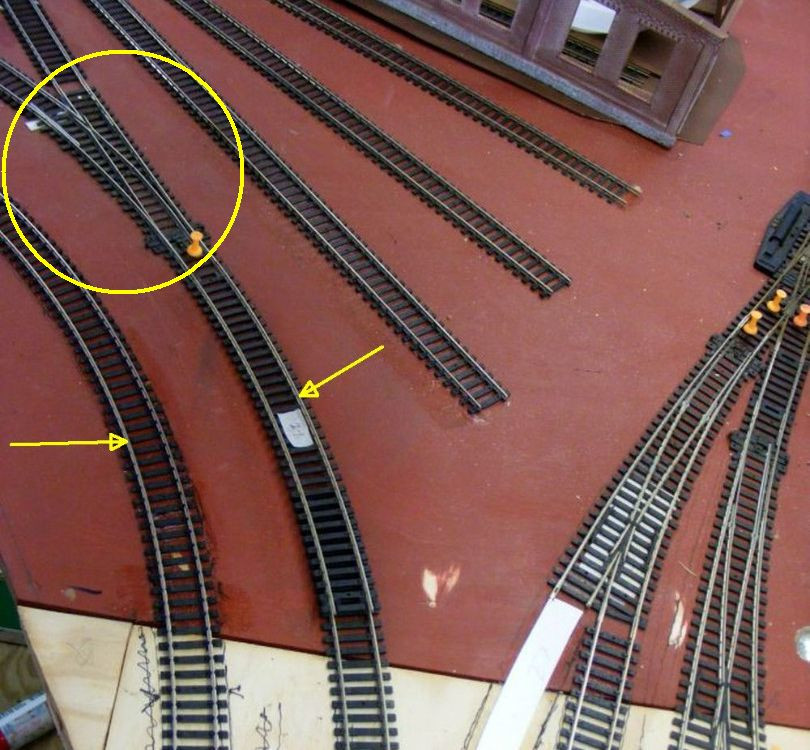

It was not as smooth (no kinks) as I had wanted. I had actually cut the diverging tracks off slightly to try and get a smoother curve.

I then became aware that the' constant 24" radius' of that stock Peco turnout was in fact not absolutely constant, nor was it all 24".

This keep wearing on my mind as it was so important for my numerous steam engines to get back to the turntable. I vowed I was going to try and fix it.

My first thought was to replace it with a Peco short Y that also is advertised as 24"radius also. But that would create an an S turn in that trackage. No, I was going to have to see if I could massage a conventional sm Peco to work. I ended up taking a brand new sm-r Peco and cutting a slot in the two ties between the V area between the 2 tracks exiting the frog,..

I then inserted a piece of plastic into that cut slot to help with maintaining that spread of the diverging tracks. Now my new modified Peco snall-r looks smoother in its overall 24" curve.

*****************

PS: It was this turnout problem that kept me looking back at this area of track, AND the reason I took a new look at providing a new connection between the 2 curves utilizing double curves,.....to be continued.