One Atlas Snap Switch remote control turnout on my small (4' x 6') layout seems to be the cause of regular derailments of my lightly-used, three-year old MTH F3 locomotives when entering the diverging route. I'm still testing the trackage, so the locos are not pulling cars as yet. When following the main route of the turnout, there is never a problem.

I've pinpointed the spot - about a 1/2" area - along points of the turnout where the front trucks of the locos (most often the "A" cab, though the "B" cab also sometimes derails) "skip" and jump the tracks just before entering the diverging route. However, when I run the "A" cab backwards, it almost always remains on the turnout and continues on its way just fine. Nothing on the front of cab "A" or on either end of cab "B" is making any contact with the turnout - or anywhere else on the entire layout.

I've carefully inspected both the turnout and the locos and can see no physical impairments or deformities on either. The rails feel smooth and all lie flat on the cork roadbed. I've tried nailing down the adjoining tracks on both ends of the turnout in different places and distances from the point of derailment to see whether the downward "pressure" they exert in keeping the tracks flat and level has any negative effect, but to no avail. I've even removed those nails altogether, but either way, I get only a brief return to flawless operation before the derailments begin again.

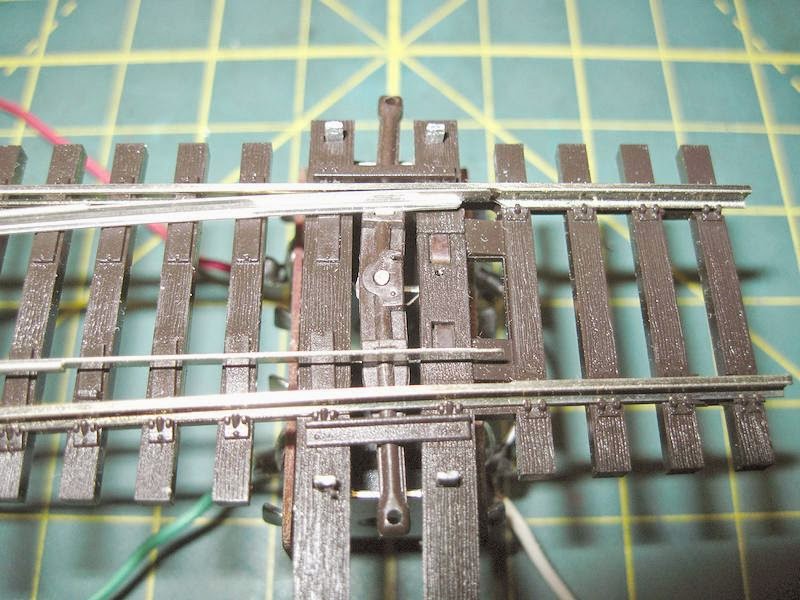

The Tortoise switch machines operating this - and all the other turnouts - move the turnout points fully and completely, as they should. One thought I've had - since the Tortoises were only recently added to the layout - is that the one operating the turnout in question is misaligned beneath the roadbed. Your thoughts on this and other possible causes - and solutions - solicited.

I've pinpointed the spot - about a 1/2" area - along points of the turnout where the front trucks of the locos (most often the "A" cab, though the "B" cab also sometimes derails) "skip" and jump the tracks just before entering the diverging route. However, when I run the "A" cab backwards, it almost always remains on the turnout and continues on its way just fine. Nothing on the front of cab "A" or on either end of cab "B" is making any contact with the turnout - or anywhere else on the entire layout.

I've carefully inspected both the turnout and the locos and can see no physical impairments or deformities on either. The rails feel smooth and all lie flat on the cork roadbed. I've tried nailing down the adjoining tracks on both ends of the turnout in different places and distances from the point of derailment to see whether the downward "pressure" they exert in keeping the tracks flat and level has any negative effect, but to no avail. I've even removed those nails altogether, but either way, I get only a brief return to flawless operation before the derailments begin again.

The Tortoise switch machines operating this - and all the other turnouts - move the turnout points fully and completely, as they should. One thought I've had - since the Tortoises were only recently added to the layout - is that the one operating the turnout in question is misaligned beneath the roadbed. Your thoughts on this and other possible causes - and solutions - solicited.