You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

post your model RR tips........

- Thread starter Greg from Mi.

- Start date

Lynnb

Well-Known Member

Sorry I don’t quite understan what you mean , when you say tread are you talking about the wheel portion that rides on the rail or the flange that catches the rail head inside edge?If you have fought with a steam engine that continually derails at turnouts, try this. I have found that the wheels of the lead truck are sometimes flat across the tread. When they come to the points the outer edge of the tread is still resting on the main rails and they fail to follow the diverging route.

Using a Dremel, grind the tread so that it tapers toward the outer end. This will ensure that the weight is carried by the diverging route rails.

dgrafix

Well-Known Member

Agreed 100% it is a degreasant and dispersant. It will act as a temporary lubricant but will eat/melt out any grease and will dry out leaving next to none. It is amazing how many people spray it on bike chains, skateboard bearings or anything that moves thinking it is an easy quick replacement for oil or grease. Perfect for cleaning your old rusty cruddy chain but you must oil it after lolWD-40 is not a lubricant it is a coating and a cleaner, when used on moving parts it acts as a cutting oil and will cause premature wear on moving parts it will also chase moisture so can be used to clean electrical connections...

Last edited:

Snowman

Well-Known Member

If you have masked off some part of a model in order to airbrush/spray or even brush paint and want a clean line or edge, don't ruin it later by pulling the tape up and away from the surface. I've seen this many times, but it can result all too often in lifting the new paint right back off again, and particularly along the newly masked line.

Instead, pull the masking tape ALONG the surface of the model as you remove it. Start at one end, gently lift it up (gently), and then once you have enough off to get hold of it (tweezers can help), fold it back over onto itself and pull the tape along the surface as you peel it off. Along, not up and away.

Instead, pull the masking tape ALONG the surface of the model as you remove it. Start at one end, gently lift it up (gently), and then once you have enough off to get hold of it (tweezers can help), fold it back over onto itself and pull the tape along the surface as you peel it off. Along, not up and away.

Selector

Well-Known Member

I would just elevate the throwbar with a shim of thin plastic. If this happens on my handlaid turnouts, I soften the solder and lift the point slightly.If you have fought with a steam engine that continually derails at turnouts, try this. I have found that the wheels of the lead truck are sometimes flat across the tread. When they come to the points the outer edge of the tread is still resting on the main rails and they fail to follow the diverging route.

Using a Dremel, grind the tread so that it tapers toward the outer end. This will ensure that the weight is carried by the diverging route rails.

shortwrench

Well-Known Member

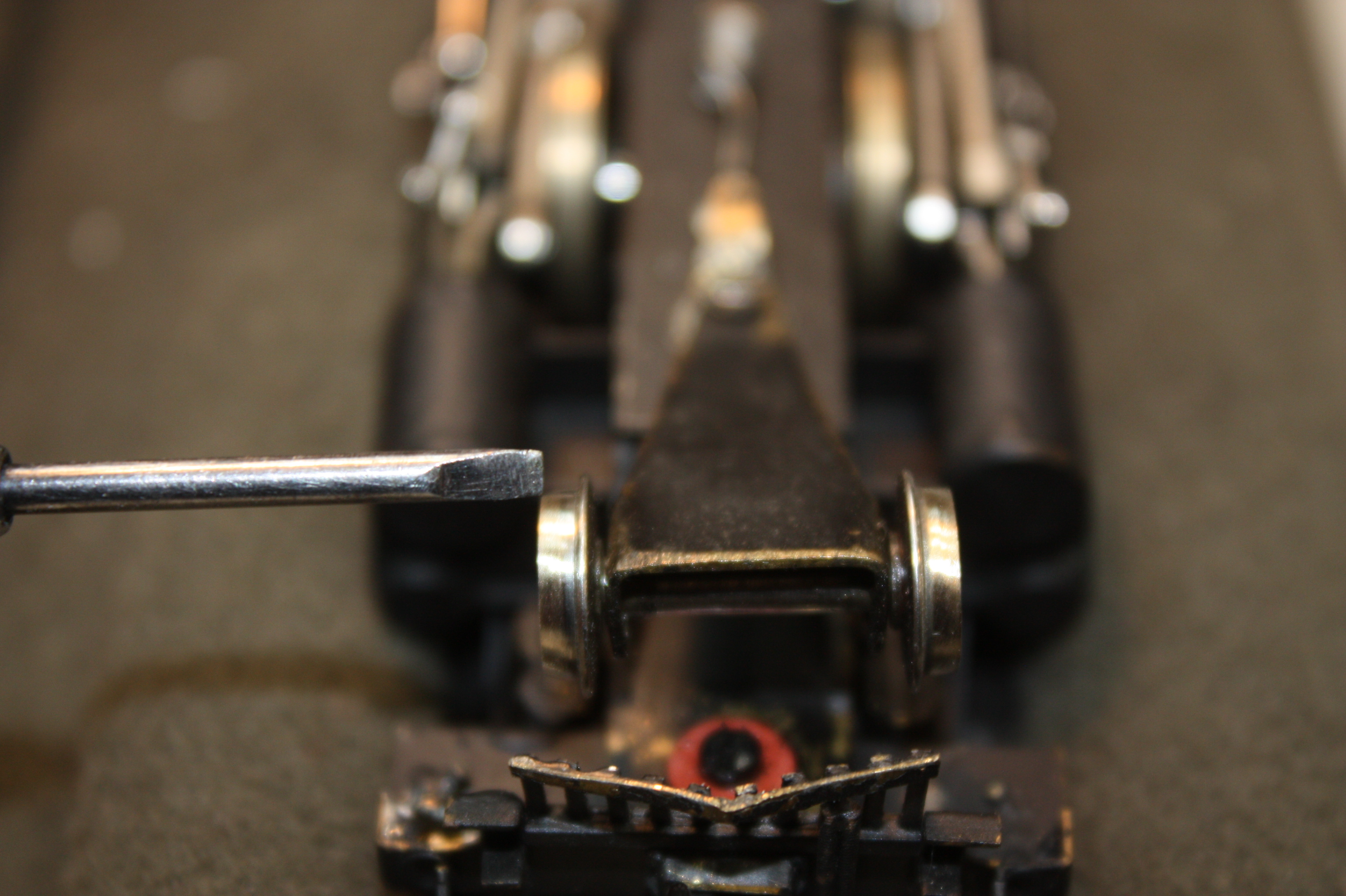

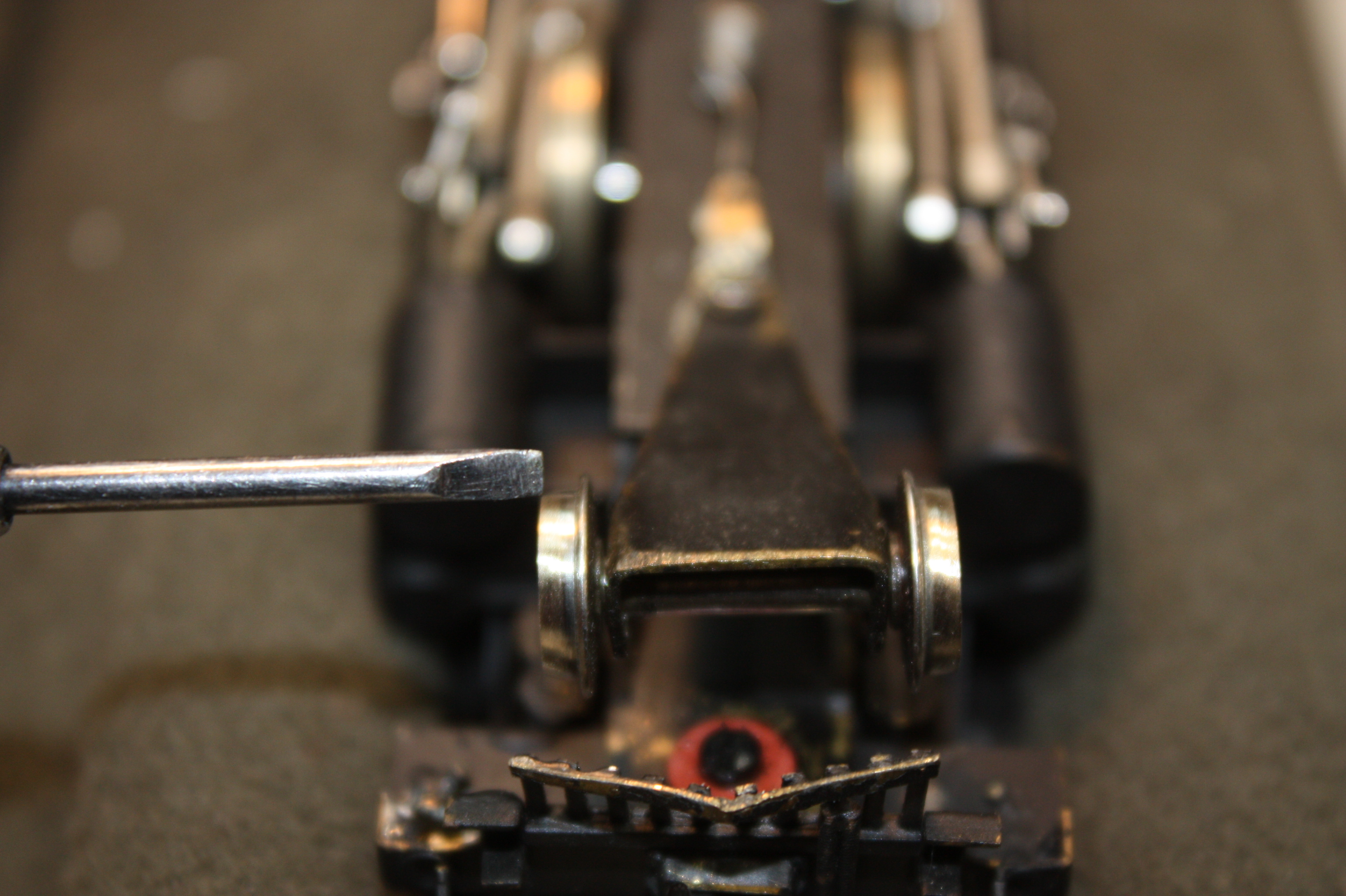

Standard practice for removing locomotive shells is the use of a small screwdriver on either side of the shell

and frame to separate them enough to clear the retaining tabs. Some locos have more than one tab on each

side of the frame and require more than one screwdriver on each side. The downside is as you apply a second

screwdriver on one side, the screwdriver already in in place on that side will want to fall over due to the

reduced pressure and high center of gravity due to the handle.

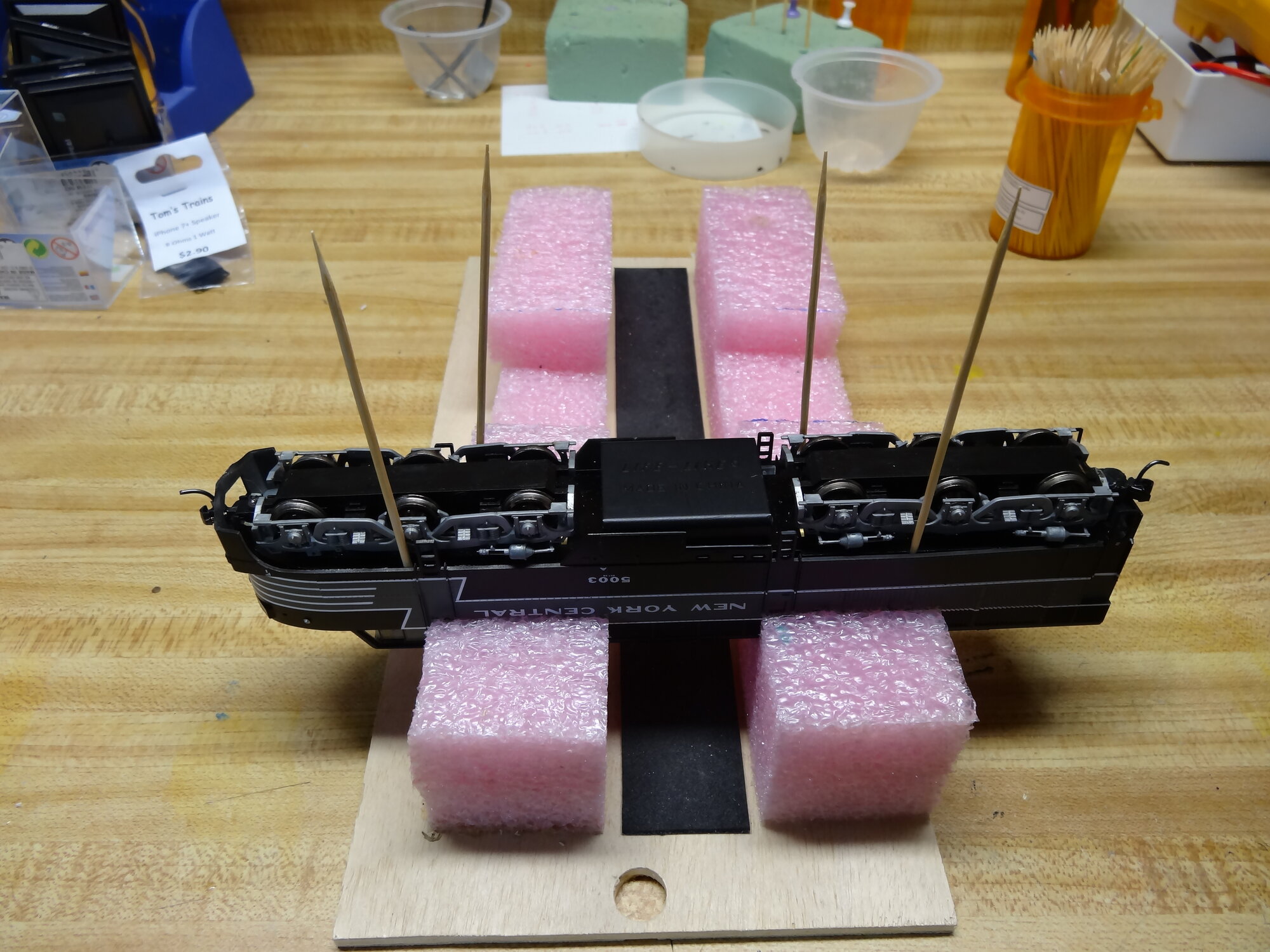

I use toothpicks instead of screwdrivers. Low mass and no high center of gravity allows them to stay in place.

Their tapered shape allows them to be progressively gradually inserted deeper for the shell to clear the tabs.

They are one of the mostly used "tools" on my workbench.

and frame to separate them enough to clear the retaining tabs. Some locos have more than one tab on each

side of the frame and require more than one screwdriver on each side. The downside is as you apply a second

screwdriver on one side, the screwdriver already in in place on that side will want to fall over due to the

reduced pressure and high center of gravity due to the handle.

I use toothpicks instead of screwdrivers. Low mass and no high center of gravity allows them to stay in place.

Their tapered shape allows them to be progressively gradually inserted deeper for the shell to clear the tabs.

They are one of the mostly used "tools" on my workbench.