Is there any way you can use cables (model aircraft etc) to transfer the movement from remotely positioned machines?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New crossing gate project

- Thread starter NYC_George

- Start date

trailrider

Well-Known Member

Well, I've been looking at that. Not sure if I have room inside the control panel, under the table top. Been thinking along those lines... Thanks for the suggestion.

goscrewyourselves

I'm the one

In line with Toot'ns thinking, there could be a way to make this work, despite the frame work. What I am thinking works on a "push/pull" wire like an old style "Choke" in a car. You could install "Push/Pull" switches in the facade of your bench work or a separate panel for them and run heavy weight wires through the frame work to where your gates and or turnouts are located. You'd need to fabricate a linkage system from the actuating wire to the cross bar for the gates and or turnouts.

Come to think about it, you don't need to have your slow motion machines directly beneath what it is you want to use them for - they too can be located away from the gates or the turnouts and use them in the same manner as the "Push/Pull" manual choke method.

Come to think about it, you don't need to have your slow motion machines directly beneath what it is you want to use them for - they too can be located away from the gates or the turnouts and use them in the same manner as the "Push/Pull" manual choke method.

The advantage of the cables and tubes used in aircraft etc is that they use nylon tubes, which have less resistance against the wire than a choke or bicycle metal tube. Actually I think even bikes use them now. Pretty sure you would also find the cranks etc that you may need in the aircraft sections of hobby shops, or online. The main trick is to keep any curves as less as possible in the runs.

NYC_George

Well-Known Member

I did the crossing video. I used a new video editor so it took a day or two to lean how to use it. Notice how slow the gates go up and down. Their a little out of sink. I'll fix that in a day or two. Enjoy the video. A fast moving freight. I added a sound track I recorded while having my car's oil changed in Rockland county, NY.

https://www.youtube.com/watch?v=i95nA8AXHOs&feature=youtu.be

https://www.youtube.com/watch?v=i95nA8AXHOs&feature=youtu.be

goscrewyourselves

I'm the one

George,

Darn, great little video mate and that was some train! As for the gates, the object of the video, I thought they went up and down nicely, not too slow at all. They look great and glad you got them working - excellent work!

Darn, great little video mate and that was some train! As for the gates, the object of the video, I thought they went up and down nicely, not too slow at all. They look great and glad you got them working - excellent work!

Iron Horseman

Well-Known Member

Then there are also "liquid levers" where one could use a syringe on either end with a plastic tube between to do a push/pull hydraulic arrangement. The nice thing about that arrangement is that one actuator could control multiple (in this case two) rams, one for each gate.In line with Toot'ns thinking, there could be a way to make this work, despite the frame work. What I am thinking works on a "push/pull" wire like an old style "Choke" in a car. You could install "Push/Pull" switches in the facade of your bench work or a separate panel for them and run heavy weight wires through the frame work to where your gates and or turnouts are located. You'd need to fabricate a linkage system from the actuating wire to the cross bar for the gates and or turnouts.

Come to think about it, you don't need to have your slow motion machines directly beneath what it is you want to use them for - they too can be located away from the gates or the turnouts and use them in the same manner as the "Push/Pull" manual choke method.

goscrewyourselves

I'm the one

Horseman,

That's an interesting idea and goes to show there are many ways of "skinning a horse"

That's an interesting idea and goes to show there are many ways of "skinning a horse"

trailrider

Well-Known Member

Thanks, all! When I have time, I'll look into the various possibilities. Meantime, everyone have a Happy Holiday Season and a Happy, Healthy and Prosperous New Year!

goscrewyourselves

I'm the one

trailrider,

You too mate and I did hear back from Suzie. A bit more to connecting up servo's than I remembered. In addition to the servo's you'd also need a "Signalist SC2" which the servo's are connected to and that, in turn, is connected to the power source. The SC2 can handle 4 turnouts per unit and cost around $45 each give or take. In so far as sped control is concerned, the SC2 is programmable for the speed of the servo by changing CV numbers in it.

While it is a good, solid and reliable option, the over all cost maybe prohibitive when compared to conventional methods.

At the end of the day, this is pretty much mute as you have your gates working very well.

You too mate and I did hear back from Suzie. A bit more to connecting up servo's than I remembered. In addition to the servo's you'd also need a "Signalist SC2" which the servo's are connected to and that, in turn, is connected to the power source. The SC2 can handle 4 turnouts per unit and cost around $45 each give or take. In so far as sped control is concerned, the SC2 is programmable for the speed of the servo by changing CV numbers in it.

While it is a good, solid and reliable option, the over all cost maybe prohibitive when compared to conventional methods.

At the end of the day, this is pretty much mute as you have your gates working very well.

Last edited by a moderator:

NYC_George

Well-Known Member

Thanks Greg. 55 cars I would added more but I only have 3 New Haven engines. Most of the people that live here remember waiting at the Rt 216 crossing for the 100 car NH trains to pass. So for all my facebook friends I wanted to keep it all NH.

George

George

goscrewyourselves

I'm the one

George,

Forgive me if this has been asked and answered; however, running a train with 55 cars attached means your layout is massive, at least to me it does. How much physical track work do you have in terms of length? Any chance of seeing your track plan perhaps?

Forgive me if this has been asked and answered; however, running a train with 55 cars attached means your layout is massive, at least to me it does. How much physical track work do you have in terms of length? Any chance of seeing your track plan perhaps?

NYC_George

Well-Known Member

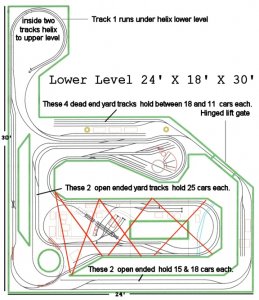

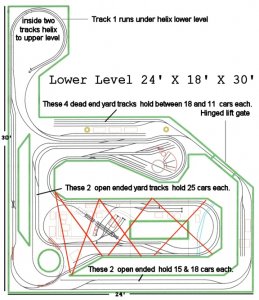

Tony to answer your question. The layout is 24' X 18 ' X 30'. Here's an old diagram of how the layout was a few years ago. The part off the layout with the red lines drawn on the diagram is gone. I wanted more space when some of my friends stop over. The helix has been moved but the dimensions are about the same.

George

George

I thought those gates looked very prototypical.

goscrewyourselves

I'm the one

George,

Thank you and, even with the center section removed, it is still an amazing layout.

Thank you and, even with the center section removed, it is still an amazing layout.