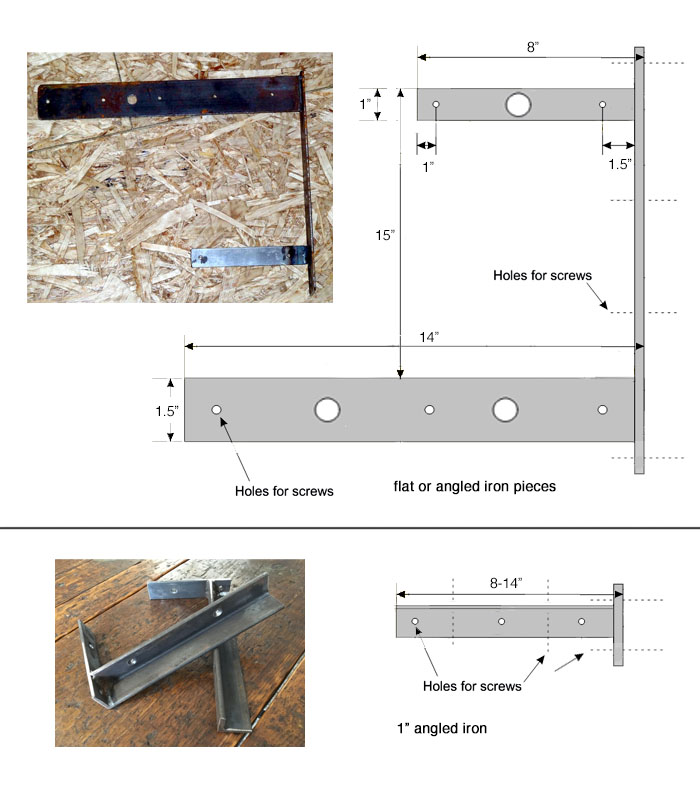

Angle-iron Brackets made from used Bed Frames

I have now changed my plans, and intend to use some brackets somewhat like you illustrated that were fabricated from angle-iron. I had some 1.5" flange angle iron I salvaged from a metal storage shelf. but I only had just so much of that material, and not enough to make all the brackets I will need.

An Idea popped into my head. Why not just use some angle-iron that can be salvaged off of bed frame mattress supports. Those bed frames are made from some very strong metal that is just the size we need to make brackets,...and they are available real cheap at thrift shops or metal scrap yards.

TrainzLuvr

Let me show you what I mean...the black bracket below (top left) was the original design I started with which I actually saw here on MRH, from Bill Brillinger

I have now changed my plans, and intend to use some brackets somewhat like you illustrated that were fabricated from angle-iron. I had some 1.5" flange angle iron I salvaged from a metal storage shelf. but I only had just so much of that material, and not enough to make all the brackets I will need.

An Idea popped into my head. Why not just use some angle-iron that can be salvaged off of bed frame mattress supports. Those bed frames are made from some very strong metal that is just the size we need to make brackets,...and they are available real cheap at thrift shops or metal scrap yards.