Why I am now backing away from this 'on-the-deck' cable system idea

1) Installation problems, and 2) Maintenance/Repair perceived problems

Lets see if I can describe the installation problems correctly. I'm laying down my cork roadbed, and track, and turnouts, exactly as I had drawn out on my brown paper pattern, while concurrently removing the paper pattern, then glueing the cork down. At this point in order to stick to my tightly configured plan I would like to glue down as much track as I could,....at least the ordinary track existing between the turnouts, as I am NOT wishing to glue the turnouts themselves down,...a no, no as I understand it.

BUT I can't really glue any of the track down yet due to 2 factors,..I have yet to cut all those slots in the roadbed for subsequent control cable routing,...and I have yet to sand/rasp those ramp areas where the cork is changing height from mainline height to yard or sidetrack heights. That cable connection to the turnouts looked so simple,..

..but then my thoughts turned to having to plan out ALL of those cables routes and cut the slots under each turnout bar, AND under subsequent roadbeds the cable would route under other tracks leading to the edge of the deck,....all before I could absolutely glue down the tracks and turnouts.

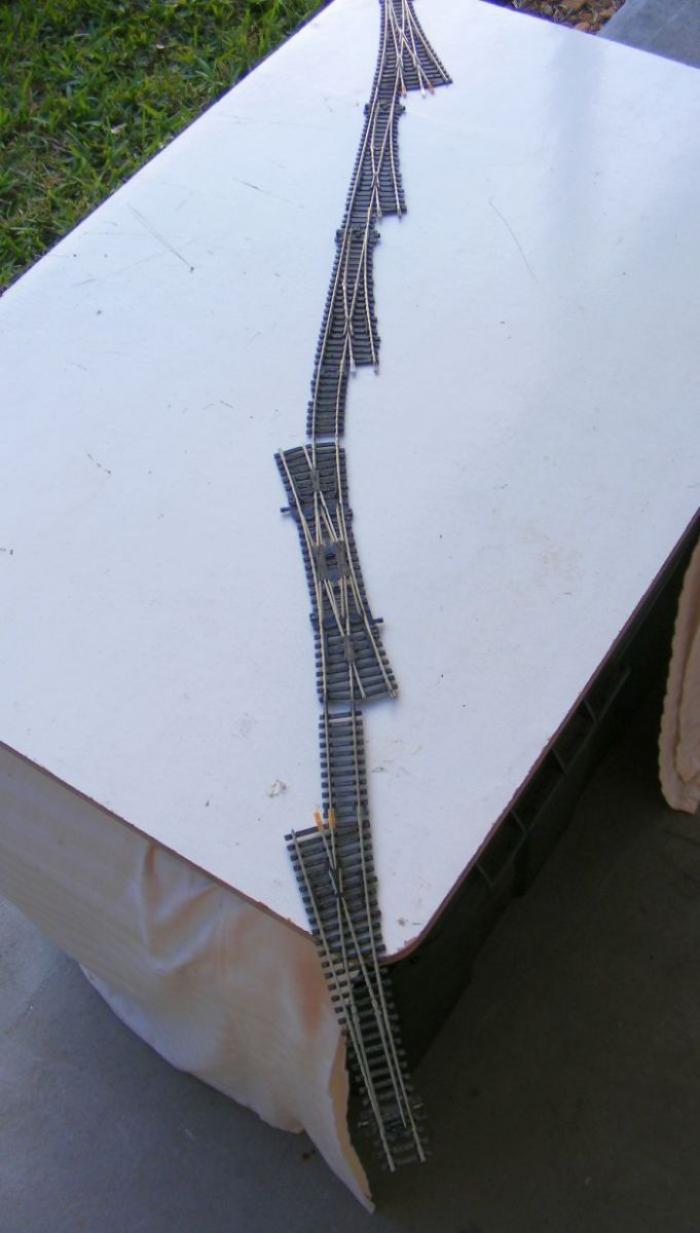

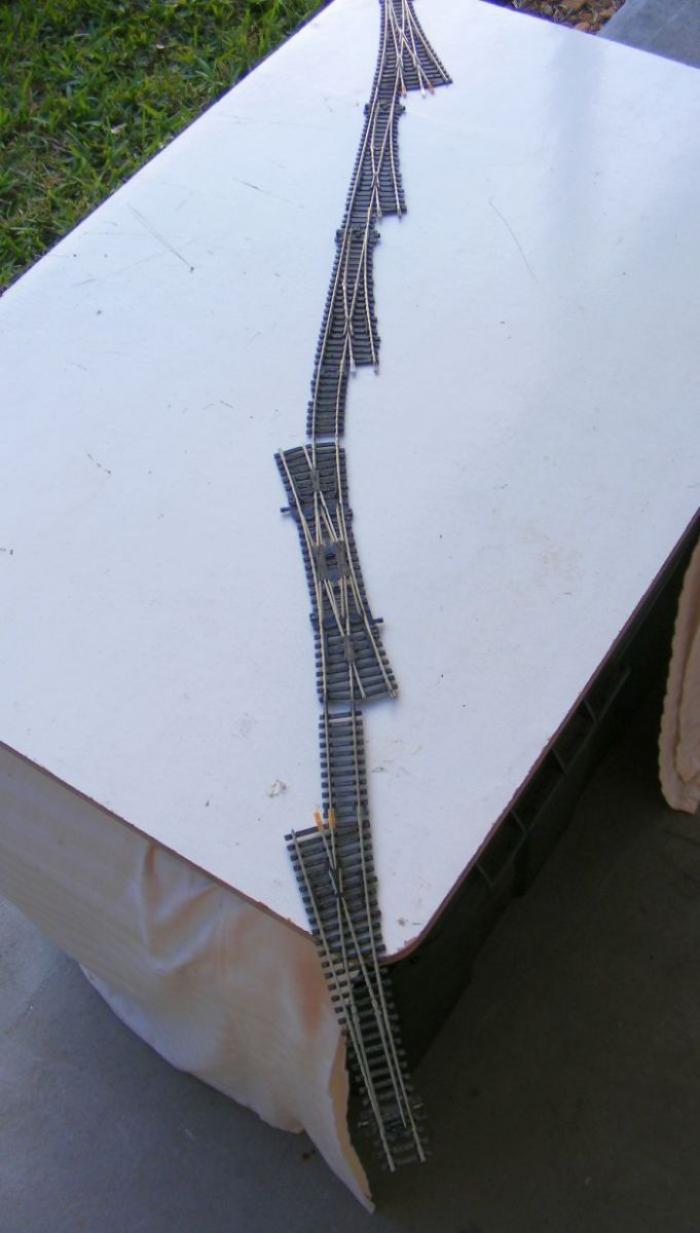

So before I could fastened down any of my track. I was going to have to connect all of those control cables to their respective turnouts and leave them lay across other trackways until I could get to them. And I was going to have to be careful keeping them all inserted up UNDER their throwbars in unison,...and particularly when I had a whole chain of them such as in a ladder situation like this,..

TOO CONFUSING, PROBLEMATIC, etc !!

...(and it had me thinking about repair/maintenance/replacement of any one of those turnouts)

So I'm going back to this idea,..

“I would like to place my tracks and turnouts down and tweak their alignments, BEFORE I have to provide that hole for the vertical rod. Only then would I need to drill that hole for the vertical tube that will house that vertical post. That tube will be a tight fit in the ¾' thick plywood, and allow the free rotation of that vertical rod/post.”

So my control cables/rods will be below decks, BUT the piano wire rod/wire that actually moves the switch throwbars will be (installed) dropped in from the top,...similar to this

https://model-railroad-hobbyist.com/node/40133?page=3#comment-447725

1) Installation problems, and 2) Maintenance/Repair perceived problems

Lets see if I can describe the installation problems correctly. I'm laying down my cork roadbed, and track, and turnouts, exactly as I had drawn out on my brown paper pattern, while concurrently removing the paper pattern, then glueing the cork down. At this point in order to stick to my tightly configured plan I would like to glue down as much track as I could,....at least the ordinary track existing between the turnouts, as I am NOT wishing to glue the turnouts themselves down,...a no, no as I understand it.

BUT I can't really glue any of the track down yet due to 2 factors,..I have yet to cut all those slots in the roadbed for subsequent control cable routing,...and I have yet to sand/rasp those ramp areas where the cork is changing height from mainline height to yard or sidetrack heights. That cable connection to the turnouts looked so simple,..

..but then my thoughts turned to having to plan out ALL of those cables routes and cut the slots under each turnout bar, AND under subsequent roadbeds the cable would route under other tracks leading to the edge of the deck,....all before I could absolutely glue down the tracks and turnouts.

So before I could fastened down any of my track. I was going to have to connect all of those control cables to their respective turnouts and leave them lay across other trackways until I could get to them. And I was going to have to be careful keeping them all inserted up UNDER their throwbars in unison,...and particularly when I had a whole chain of them such as in a ladder situation like this,..

TOO CONFUSING, PROBLEMATIC, etc !!

...(and it had me thinking about repair/maintenance/replacement of any one of those turnouts)

So I'm going back to this idea,..

“I would like to place my tracks and turnouts down and tweak their alignments, BEFORE I have to provide that hole for the vertical rod. Only then would I need to drill that hole for the vertical tube that will house that vertical post. That tube will be a tight fit in the ¾' thick plywood, and allow the free rotation of that vertical rod/post.”

So my control cables/rods will be below decks, BUT the piano wire rod/wire that actually moves the switch throwbars will be (installed) dropped in from the top,...similar to this

https://model-railroad-hobbyist.com/node/40133?page=3#comment-447725