grande man

Bonafied Grande Nut

Hi all. Here's a "how-to" for making semi-scrath built searchlight signals. Now, before I go any further I want to say, I certainly don't feel qualified to teach many of ya'll anything. I just thought this would be a fun post for someone who's looking at signalling their RR and likes "Projects". Keep in mind as you're reading this, there's usually a right way, wrong way, and Grande Man's way of doing things.

Keep in mind as you're reading this, there's usually a right way, wrong way, and Grande Man's way of doing things.  I'm not sure how much interest there is in building signals, but it's a fun project if you're so inclined. It's some tedious detail work. If you're not into that, the price of prebuilt signals will be money well spent.

I'm not sure how much interest there is in building signals, but it's a fun project if you're so inclined. It's some tedious detail work. If you're not into that, the price of prebuilt signals will be money well spent.

I started out building an Oregon Rail Supply signal kit I found at the LHS. While there, I noticed they had ORS searchlight (and standard) signal targets in stock. We had 3/32" brass tubing and brass wire at home, so all that was required was the targets and some Miniatronics 3mm bi-polar LEDs.

What follows is a simple description of the process, photos and a materials list. You may notice that some of the instructions seem to be slightly out of step with the pics. Does "school of hard knocks" mean anything to you? I'd suggest you do as I say and not as I did...

I'd suggest you do as I say and not as I did...

Materials List:

Materials

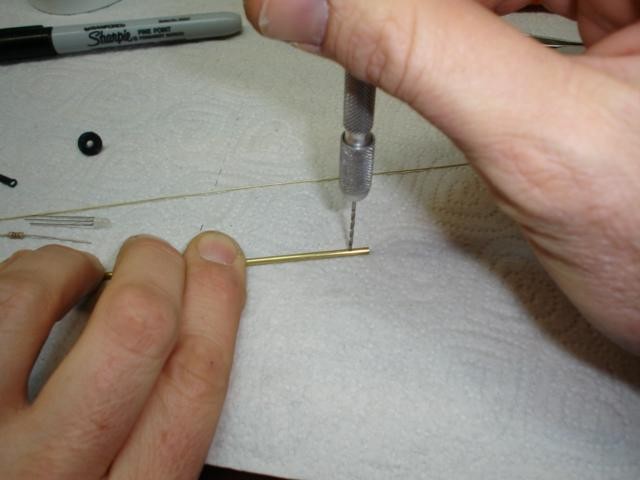

First, drill a .050" hole about 1/4" from one end of the brass tube. Tube length can vary, as you'll soon see. While less than 4" of the signal will be visable on the layout, I went with an 8" section of tubing because the area this signal will be installed has a 4" thick foam subroadbed. The extra length prevented me from having to fish the wiring thru the foam.

Next, solder a wire to the opposite end of the signal mast from the hole you just drilled. Solid conductor phone wire woks well. This will be the common wire and will need a 470 Ohm limiting resistor to protect the LED during use. By installing the resistor on the common (ground) side of the circuit, the need for two resistors is eliminated. The Miniatronics LEDs come with the resisitors, so you won't need to purchase them separately.

Because the target on a proto searchlight is typically installed off center of the mast, the mount provided in the ORS kit needs to be trimmed at an angle.

Since the target mount has an undersized hole, open it up to the correct size. I used a #40 drill bit.

After the mount is prepped, install the mast base (from the top, opposite the wire you just soldered) and then the target mount itself on the brass tube. A base can be kitbashed to form a "relay cabinet" or the sunshade from a signal target can be removed, and the target inverted to form a base for use with a separate relay cabinet. After using both methods, I prefer the latter as I like the look of a separate relay cabinet. I bonded the base to give a signal height of 3.1". That's about what the factory ORS kit I'd previously built came out to.

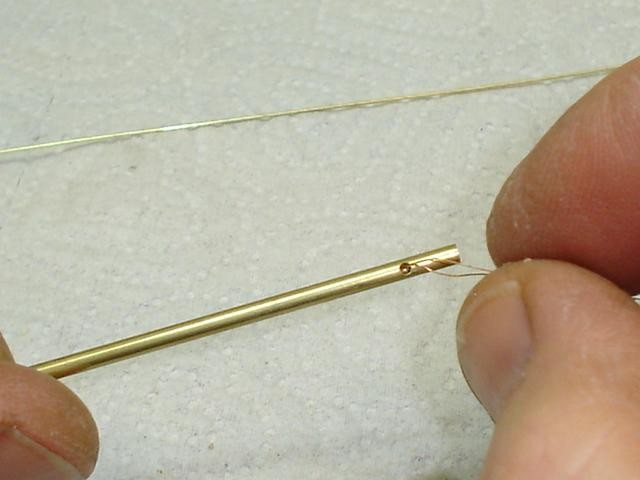

Feed two small, coated wires gently thru the hole in the top of the mast. I used wires from an old Athearn motor, but would recommend something a little heavier. I'm guessing coated wire could be purchased by the roll at Radio Shack. The Athearn motor wires are very delicate! Vinyl insulated wires are out due to size requirements. This is especially true for multi head signals.

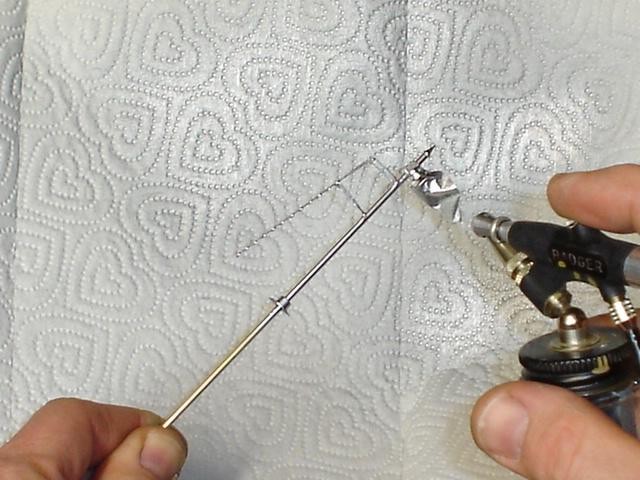

Bond the target mount to the brass tube with CA slightly above the .050" hole. You'll have to fit it in such a way that the hole for the LEDs wiring will be in the right spot. Next, bond the target to the mount. Bond the fenial (provided in the ORS kit) to the top of the mast. The LED can now be installed. I used Testors Clear Parts Cement to bond and seal the LED to the target so paint won't wick between the two. Cut the LED's center leg to to length and carefully solder it to the signal mast. Cut the other two LED legs to the proper length and solder a wire to each. The coated wire should have the coating carefully removed from a small area near it's end before soldering. This will ensure proper electrical contact. HINT: lightly tin the LED legs (wires) and the coated wire before soldering. Soldering needs to be accomplised quickly and with minimal heat transfer to the LED!!!

At this point, what you have should resemble this.

For the ladder/service platform, you'll need the .020" brass wire. Using the flux, solder the rungs in place. Keep in mind, the top will need a length of wire above the top rung to form the handrails and top of the service platform. I just made a ladder that I thought "looked right" in regard to width and rung spacing, nothing to high tech here. The trick to this type soldering is a fine tipped iron and flux. With the tip of the iron lightly "tinned", quickly solder a joint so as to not build up excess solder and ruin the ladder's dimensions.

This view shows the ladder/service platform installed. I'd recommend that soldering be done as quickly and deliberately as possible to prevent melting the coating off the LED wires inside the mast. If this is a concern, the wires could be routed after the soldering is complete. Cut a piece of "grate" from the hairnet material and CA it in place on the service platform. I installed an optional styrene cover for the LED wiring on this signal. The cover shown was "fine tuned" from what's shown in the pic.

For a smooth mast, gently scrape away excess solder using an Exacto blade at a 90 degree angle.

Tape the forward target face and paint the entire signal silver. After the silver dries, hand brush the target face flat black.

DON'T FORGET to add the resistor on the COMMON wire (the one from the mast). That's important.

Congratulations! You're now the proud owner of a semi scratched searchlight signal!

Here's a few views of the finished product...

I started out building an Oregon Rail Supply signal kit I found at the LHS. While there, I noticed they had ORS searchlight (and standard) signal targets in stock. We had 3/32" brass tubing and brass wire at home, so all that was required was the targets and some Miniatronics 3mm bi-polar LEDs.

What follows is a simple description of the process, photos and a materials list. You may notice that some of the instructions seem to be slightly out of step with the pics. Does "school of hard knocks" mean anything to you?

Materials List:

- 3/32" Brass Tubing (K&S brand, available at the LHS or Hobby Lobby)

- Solder

- Paste Flux

- 020" Brass Wire

- 3mm Bi-Polar LED (3 post, Miniatonics #12-230-05)

- Oregon Rail Supply "Single LIght Target" Kit (#102)

- Flat Black, Silver Paint

- 5 Minute Epoxy

- Medium CA

- Testors Clear Parts Cement

- Hairnet material

- Thin Sheet Styrene (optional)

Materials

First, drill a .050" hole about 1/4" from one end of the brass tube. Tube length can vary, as you'll soon see. While less than 4" of the signal will be visable on the layout, I went with an 8" section of tubing because the area this signal will be installed has a 4" thick foam subroadbed. The extra length prevented me from having to fish the wiring thru the foam.

Next, solder a wire to the opposite end of the signal mast from the hole you just drilled. Solid conductor phone wire woks well. This will be the common wire and will need a 470 Ohm limiting resistor to protect the LED during use. By installing the resistor on the common (ground) side of the circuit, the need for two resistors is eliminated. The Miniatronics LEDs come with the resisitors, so you won't need to purchase them separately.

Because the target on a proto searchlight is typically installed off center of the mast, the mount provided in the ORS kit needs to be trimmed at an angle.

Since the target mount has an undersized hole, open it up to the correct size. I used a #40 drill bit.

After the mount is prepped, install the mast base (from the top, opposite the wire you just soldered) and then the target mount itself on the brass tube. A base can be kitbashed to form a "relay cabinet" or the sunshade from a signal target can be removed, and the target inverted to form a base for use with a separate relay cabinet. After using both methods, I prefer the latter as I like the look of a separate relay cabinet. I bonded the base to give a signal height of 3.1". That's about what the factory ORS kit I'd previously built came out to.

Feed two small, coated wires gently thru the hole in the top of the mast. I used wires from an old Athearn motor, but would recommend something a little heavier. I'm guessing coated wire could be purchased by the roll at Radio Shack. The Athearn motor wires are very delicate! Vinyl insulated wires are out due to size requirements. This is especially true for multi head signals.

Bond the target mount to the brass tube with CA slightly above the .050" hole. You'll have to fit it in such a way that the hole for the LEDs wiring will be in the right spot. Next, bond the target to the mount. Bond the fenial (provided in the ORS kit) to the top of the mast. The LED can now be installed. I used Testors Clear Parts Cement to bond and seal the LED to the target so paint won't wick between the two. Cut the LED's center leg to to length and carefully solder it to the signal mast. Cut the other two LED legs to the proper length and solder a wire to each. The coated wire should have the coating carefully removed from a small area near it's end before soldering. This will ensure proper electrical contact. HINT: lightly tin the LED legs (wires) and the coated wire before soldering. Soldering needs to be accomplised quickly and with minimal heat transfer to the LED!!!

At this point, what you have should resemble this.

For the ladder/service platform, you'll need the .020" brass wire. Using the flux, solder the rungs in place. Keep in mind, the top will need a length of wire above the top rung to form the handrails and top of the service platform. I just made a ladder that I thought "looked right" in regard to width and rung spacing, nothing to high tech here. The trick to this type soldering is a fine tipped iron and flux. With the tip of the iron lightly "tinned", quickly solder a joint so as to not build up excess solder and ruin the ladder's dimensions.

This view shows the ladder/service platform installed. I'd recommend that soldering be done as quickly and deliberately as possible to prevent melting the coating off the LED wires inside the mast. If this is a concern, the wires could be routed after the soldering is complete. Cut a piece of "grate" from the hairnet material and CA it in place on the service platform. I installed an optional styrene cover for the LED wiring on this signal. The cover shown was "fine tuned" from what's shown in the pic.

For a smooth mast, gently scrape away excess solder using an Exacto blade at a 90 degree angle.

Tape the forward target face and paint the entire signal silver. After the silver dries, hand brush the target face flat black.

DON'T FORGET to add the resistor on the COMMON wire (the one from the mast). That's important.

Congratulations! You're now the proud owner of a semi scratched searchlight signal!

Here's a few views of the finished product...