KB02

Well-Known Member

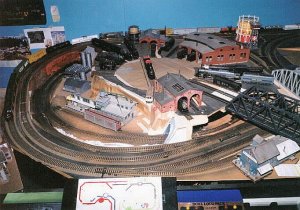

Alright, since I can't seem to talk myself out of this, and no one else is rushing in to talk me out of it either (thanks a lot guys!), it looks like I am going to try my hand at building a turntable for my layout. This should be entertaining if nothing else. This will be a long term project. I am in the middle of a job change (new job for new year), so my energy might be elsewhere for a little bit in a few weeks. I've got the basics figured out in my head, now I'll see if I can bring them into reality. I need a 100' foot bridge on my turntable, and there are quite a lot of 90' and 130' jobs out there, but not many 100's. The ones I have found are expensive! My theory is that I can build one cheaper than buying one so I am going to try to keep a running tally of material costs, too, to see just how far into debt I go through this project (and if I would have been better off just buying one instead).

Worth a shot, right?

So, to start with, my wife gave me a bunch of modeling supplies for Christmas which included two sheets of 1/4"x4"x3' Balsa and two sheets of 1/8"x4"x3' Balsa. I'm going include that into the total at roughly $5.00. I'm not going to include any tool costs, either, unless there is something super special that I have to get to make this project work.

So, without further delay: Stage One - The bridge!

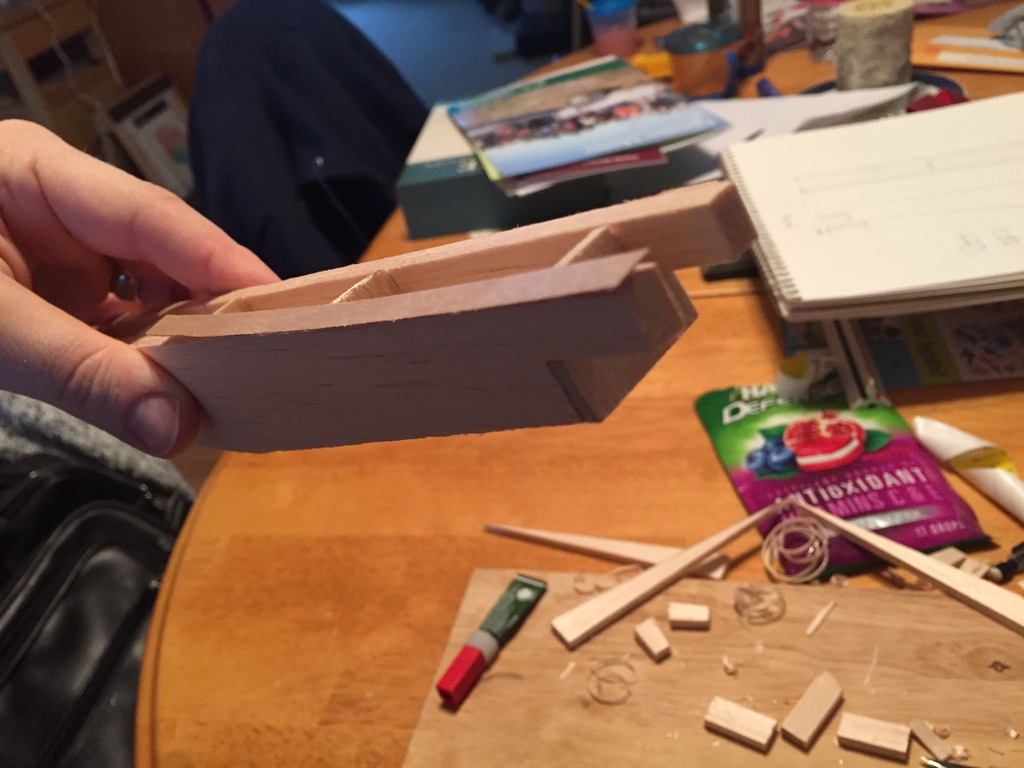

Starting by cutting out blanks for the bridge side out of the 1/4" balsa:

Then I drew out the design of the bridge halves on the blanks:

Next, cut them out:

I found the best way to do this was to draw out the design on both sides of the blank and then use a straight edge to start cutting the lines on each side. Cutting on one side seemed to cause the wood to cut at a bit of an angle (hence the shavings in the picture).

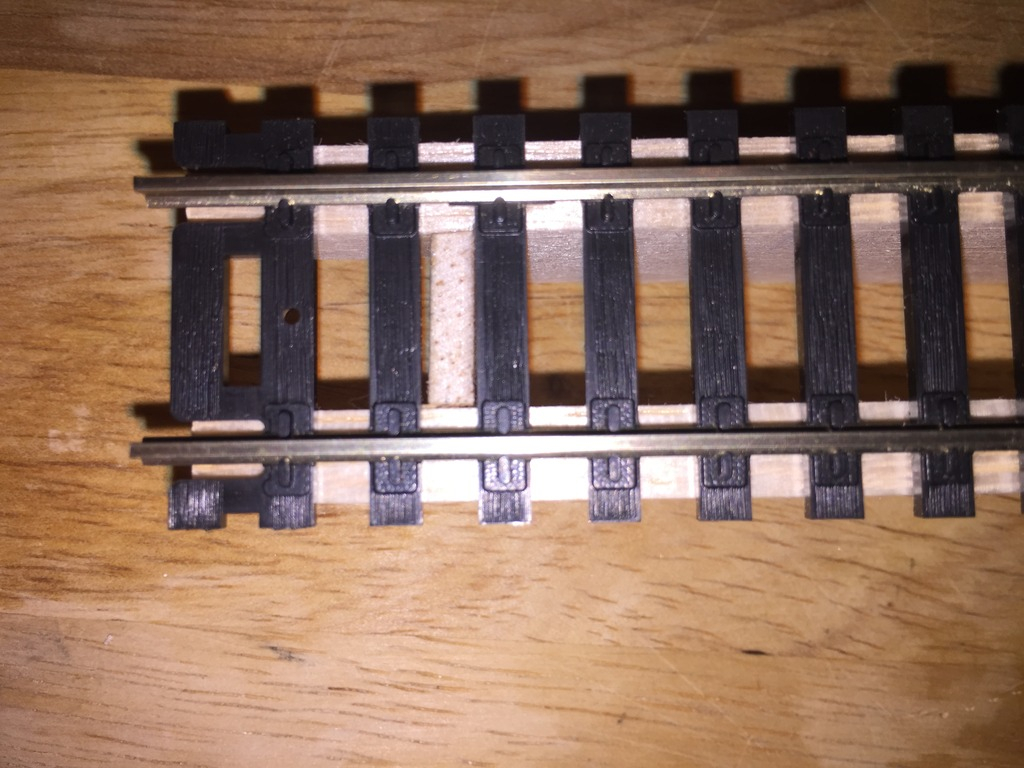

Interior supports to hold the two sides together out of the 1/8" balsa holding the side at 1/2" apart:

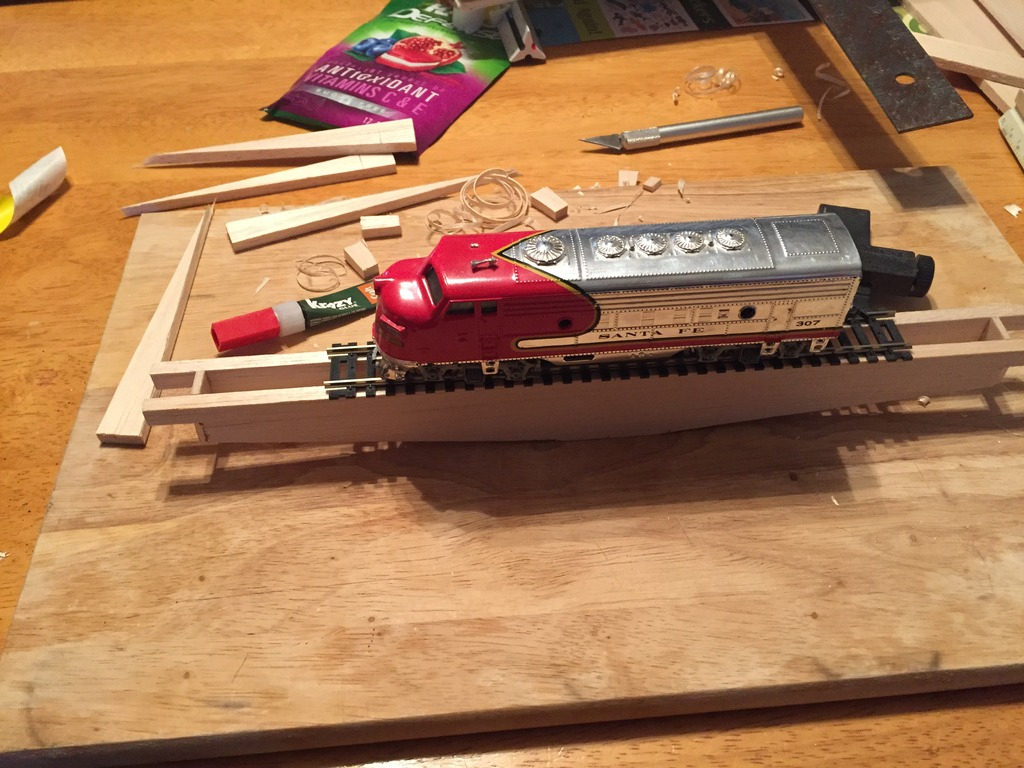

And Proof of concept for basic bridge design:

I am using Atlas Code 100 track. With the 1/2" space between the two 1/4" sides, the track hangs over the edges by about 1/16" on both sides.

I am going to use some thin birch veneer cut to roughly 5/16" to hang on the edges all around the outside of the bridge to 1.) make up the difference, and 2.) Create the the angle iron look of a real bridge.

This is where I ran out of steam, so to speak, as I only had the one small strip of veneer to play with. I will need to get some more to finish the bridge. I plan to make small score lines down the sides of the bridge into which I can insert strips of the veneer. Then I will be able to prime it, paint it and weather it (or so the theory goes).

SO: Stage 1 70% complete:

Stage 2 will be making the pit. I know some great tricks on how to cut prefect circles out of plywood. I have been brain storming and think I have a pretty good idea on how to make it.

Stay tuned....

Worth a shot, right?

So, to start with, my wife gave me a bunch of modeling supplies for Christmas which included two sheets of 1/4"x4"x3' Balsa and two sheets of 1/8"x4"x3' Balsa. I'm going include that into the total at roughly $5.00. I'm not going to include any tool costs, either, unless there is something super special that I have to get to make this project work.

So, without further delay: Stage One - The bridge!

Starting by cutting out blanks for the bridge side out of the 1/4" balsa:

Then I drew out the design of the bridge halves on the blanks:

Next, cut them out:

I found the best way to do this was to draw out the design on both sides of the blank and then use a straight edge to start cutting the lines on each side. Cutting on one side seemed to cause the wood to cut at a bit of an angle (hence the shavings in the picture).

Interior supports to hold the two sides together out of the 1/8" balsa holding the side at 1/2" apart:

And Proof of concept for basic bridge design:

I am using Atlas Code 100 track. With the 1/2" space between the two 1/4" sides, the track hangs over the edges by about 1/16" on both sides.

I am going to use some thin birch veneer cut to roughly 5/16" to hang on the edges all around the outside of the bridge to 1.) make up the difference, and 2.) Create the the angle iron look of a real bridge.

This is where I ran out of steam, so to speak, as I only had the one small strip of veneer to play with. I will need to get some more to finish the bridge. I plan to make small score lines down the sides of the bridge into which I can insert strips of the veneer. Then I will be able to prime it, paint it and weather it (or so the theory goes).

SO: Stage 1 70% complete:

Stage 2 will be making the pit. I know some great tricks on how to cut prefect circles out of plywood. I have been brain storming and think I have a pretty good idea on how to make it.

Stay tuned....