Bruce Kingsbury

New Member

OK. Got a table.... sort of. 3'x5'

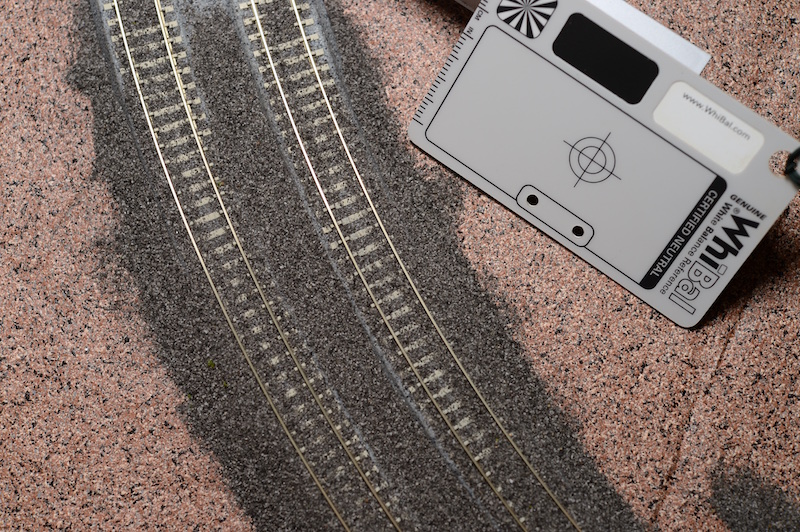

Got about $600 worth of Kato Unitrack. with a TON of switches and all sorts of straight and curved pieces.

I even figured out how to stick one track to another! LOL

Actually I am not quite that raw but pretty close. I've fooled with Atlas track before and got tired of melting ties off while leaning across that 4' wide table shoved up against the wall so I have no back side access. I can only guess the more experienced modellers here are counting the lessons I have learned and the ones I haven't realized I have learned already.

Yes, I went the way of Kato to make getting something up and running easier. I learned with oil painting if you get a success early on you are more likely to stick with whatever you are trying. That's why I scrapped the Atlas stuff and went with Kato. Thinking it might give me more of a success early on.

It has, or was until I dug out that cute little #4 switch and tried to plug it into the trial layout I was fooling with last night. Why would anybody ever design a turn out that you cannot plug any other piece of track onto the turn side? It don't make sense to me. I've learned that when I think that.... I have missed something. And thoughts other than surgically cutting the ballast off a piece of track to make/force it to fit?

Got about $600 worth of Kato Unitrack. with a TON of switches and all sorts of straight and curved pieces.

I even figured out how to stick one track to another! LOL

Actually I am not quite that raw but pretty close. I've fooled with Atlas track before and got tired of melting ties off while leaning across that 4' wide table shoved up against the wall so I have no back side access. I can only guess the more experienced modellers here are counting the lessons I have learned and the ones I haven't realized I have learned already.

Yes, I went the way of Kato to make getting something up and running easier. I learned with oil painting if you get a success early on you are more likely to stick with whatever you are trying. That's why I scrapped the Atlas stuff and went with Kato. Thinking it might give me more of a success early on.

It has, or was until I dug out that cute little #4 switch and tried to plug it into the trial layout I was fooling with last night. Why would anybody ever design a turn out that you cannot plug any other piece of track onto the turn side? It don't make sense to me. I've learned that when I think that.... I have missed something. And thoughts other than surgically cutting the ballast off a piece of track to make/force it to fit?