Hi Taihoku,

Yes welcome to the forum you'll enjoy it here.

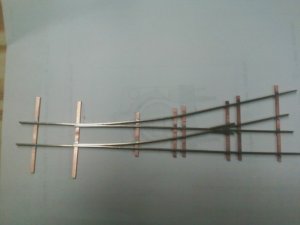

I have many years of experience hand laying track in HO and am currently using both code 70 & 55 on my layout, an Early 1900's theme. I have some various shots on the forum here too. I also build all my switches from just a paper template or even a drawing using at least a pair of three point guages if not two pair and they work fine. For straight track and especially laying curves at least three pair if not four of guages are needed to help hold the rail in position and allignmet.

Micro Engineering http://microengineering.com/, [A supply source I did have available through my distributor till the owner died so now I'm geting reistablished again], is the site you want to go to for most of your supply needs as they have both code 40 and 55 rail available as well as the spikes, ties and the apropriate three point track guages you'll need. If I can get restablished I can possibly offer you some better pricing on these items! I think you should be able to get by with guages for code 55 rail to handle code 40 too as I use my code 70 guages to also work with code 55 and don't really notice any difference. There's only a few thousands differences in the actual rail head width anyway.

The beauty of building your own switches/turnouts and handlaying your own track is that you have total flexability in the creation of the switch to suit your given situation just like on the real RR. Also, you can build not only your Standard style of switch but also a Stub switch if your lacking space.

The guy that showed me how to build switches had an N scale layout with all hand laid track in code 55 and 40 as well as switches and his trains ran great as do mine and you can't beat the realism.

You will need some,

Fine Cut Jewelers files as well as some decent rail nippers and a decent Razor Saw as well as a good hand vise or small table vise to hold the rail easily when cutting it although nippers and files work pretty well in most cases. Micro Mark will probably have most of the latter things mentioned.

I can show you the tricks to build turnouts easily too using PC strips to solder the rail to in a few places before spiking it down.

As far as a soldering iron you only need one with a fairly light tip such as an ungar with inter interchangeable tips as you don't really need too much heat.

This should give you a good start to getting things together for yourself. Who knows, you might decide to build a layout too or even encorporate your diorama into a layout!

Let me know if I can help you more.