tankist

Active Member

Just wondering, what are the dimensions of this layout, and were is your new addition?

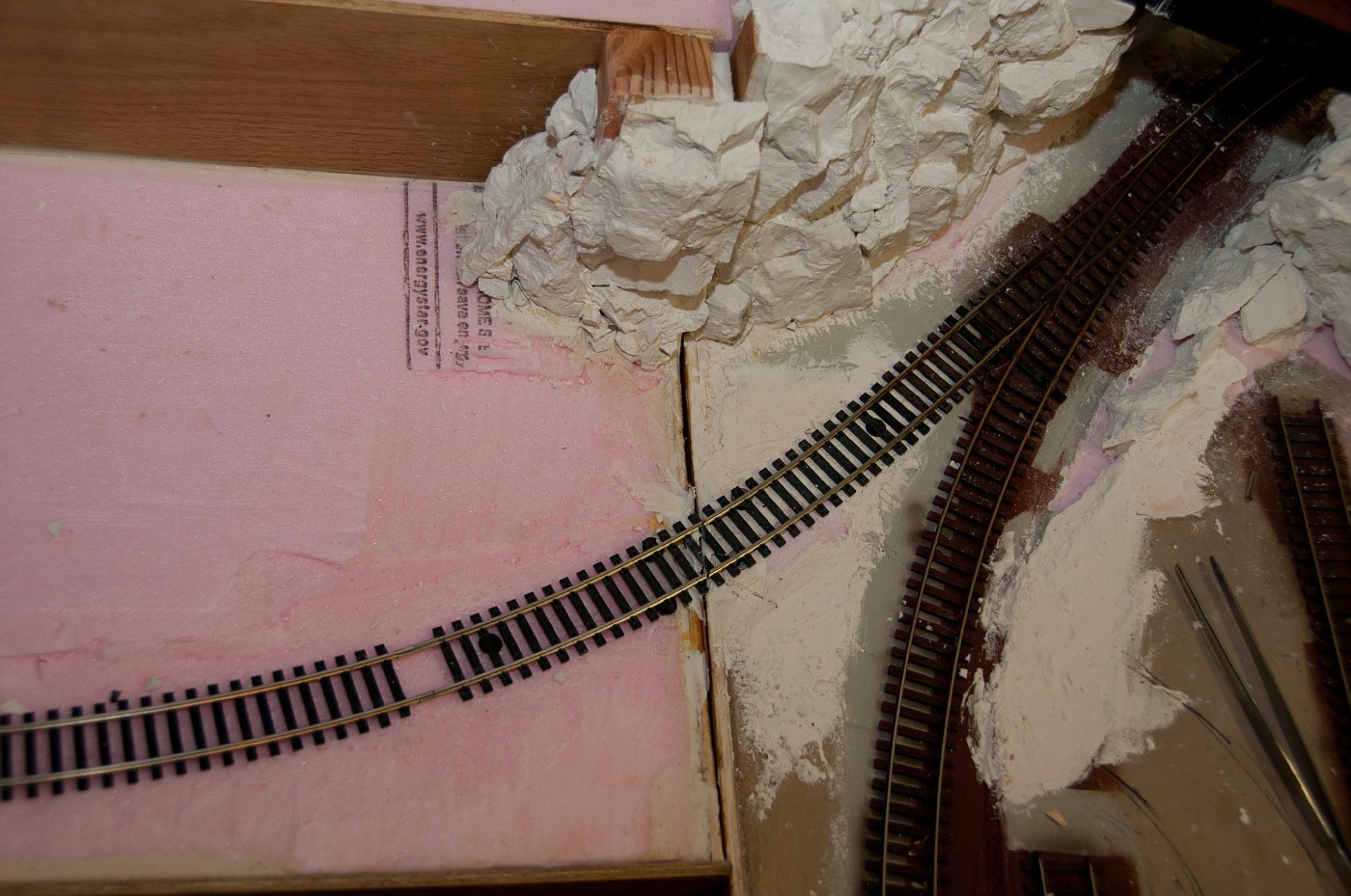

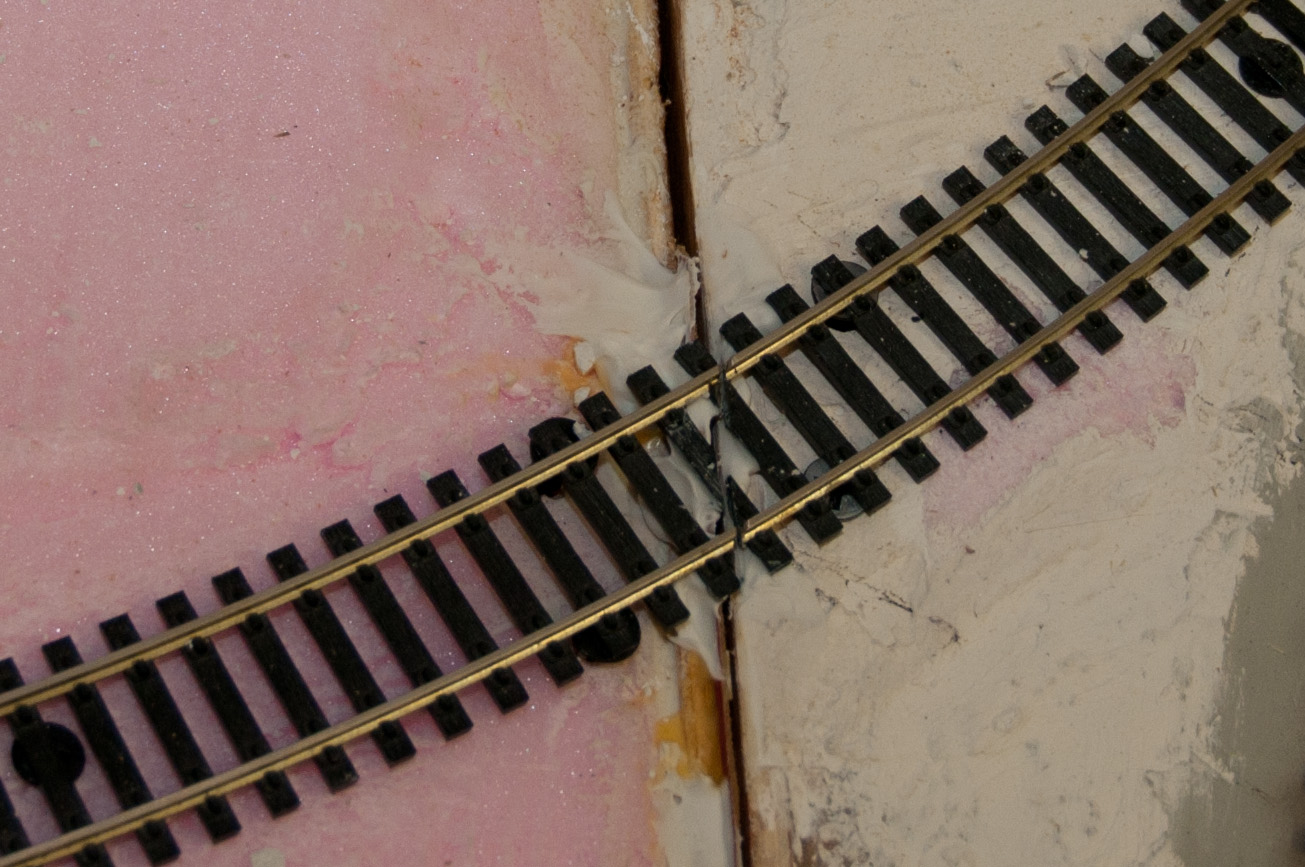

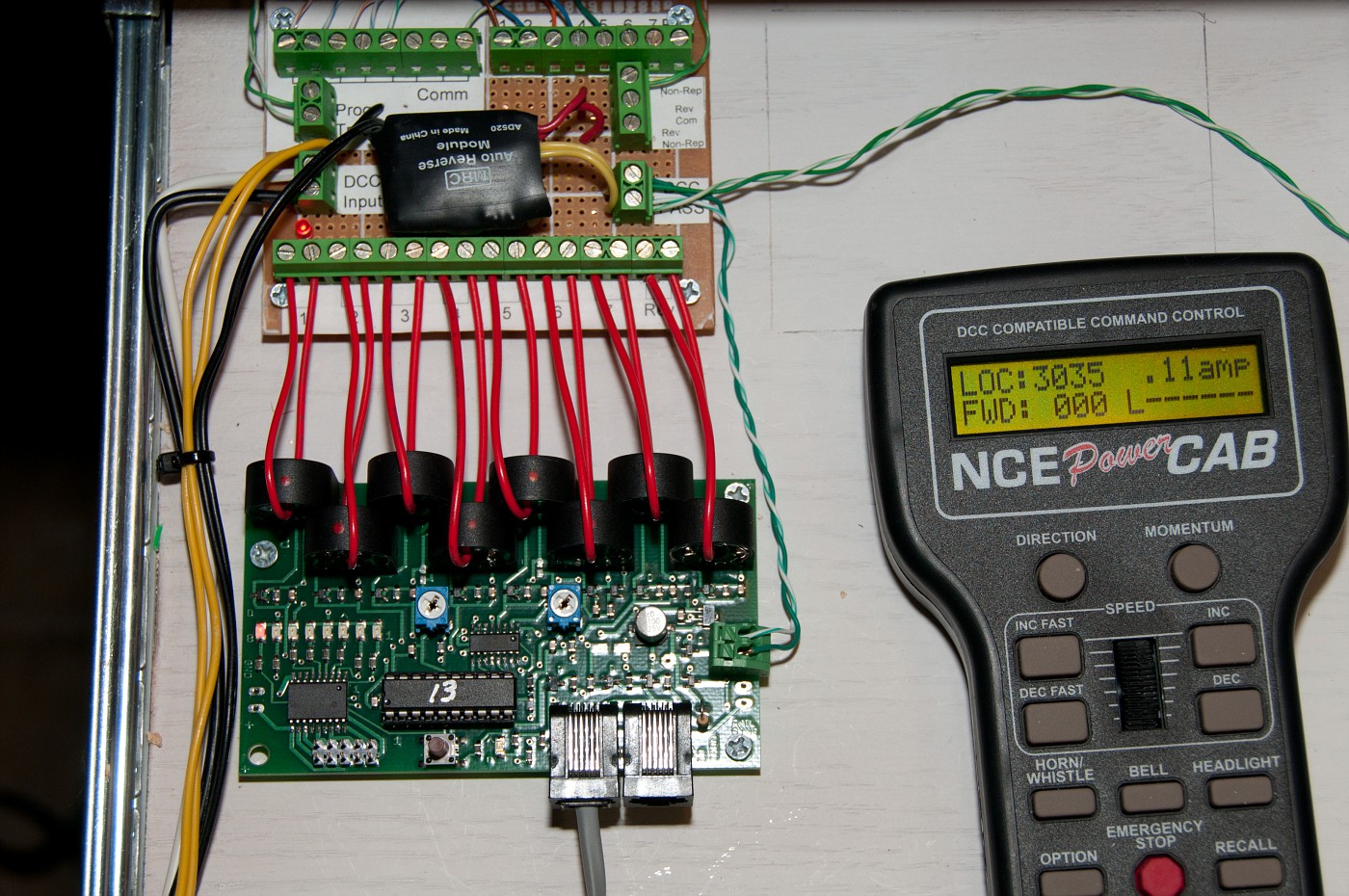

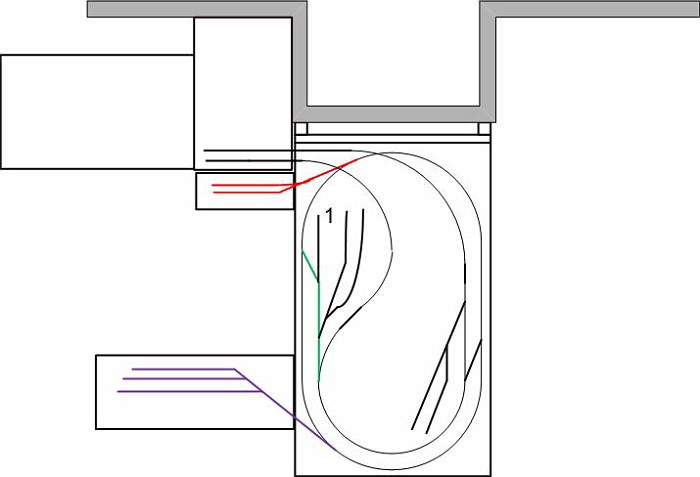

i did not make a more recent drawing. main module is 4x7. the purple setion was canceled, as i found out i was to optimistic about space it will take. the red section (the latest addition) is 7 feet by 11 inches shelf