tankist

Active Member

it is almost 4AM...

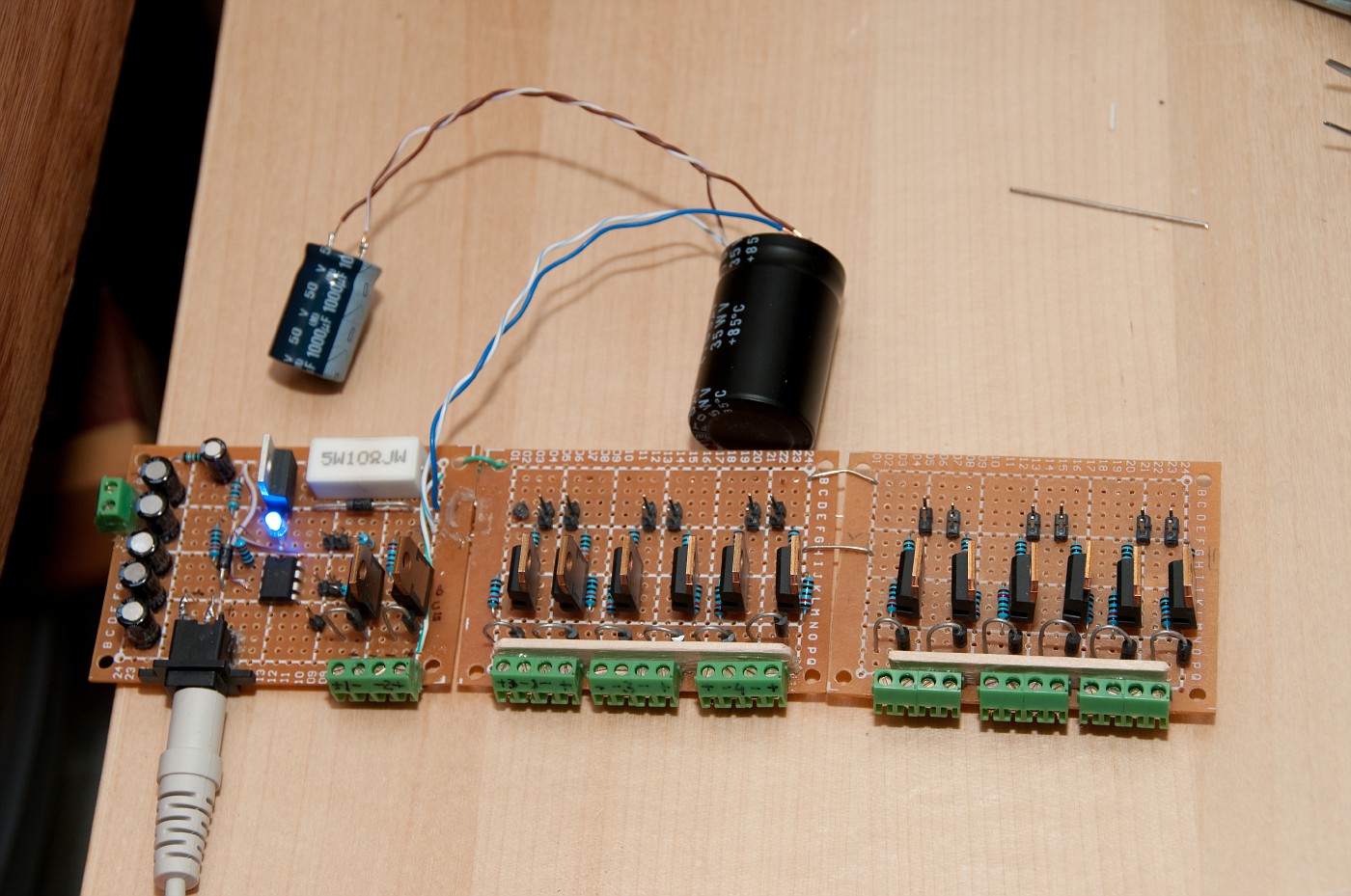

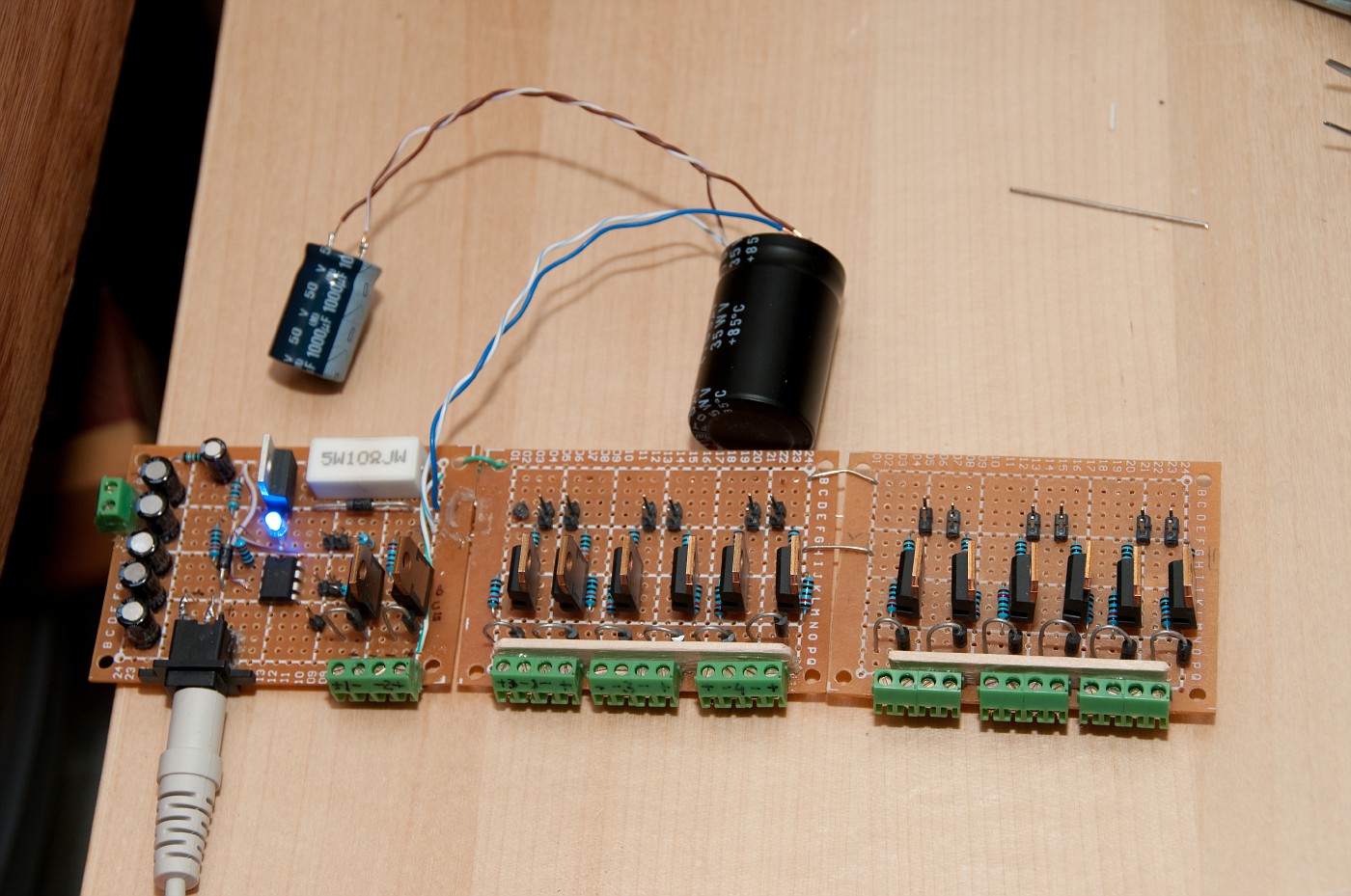

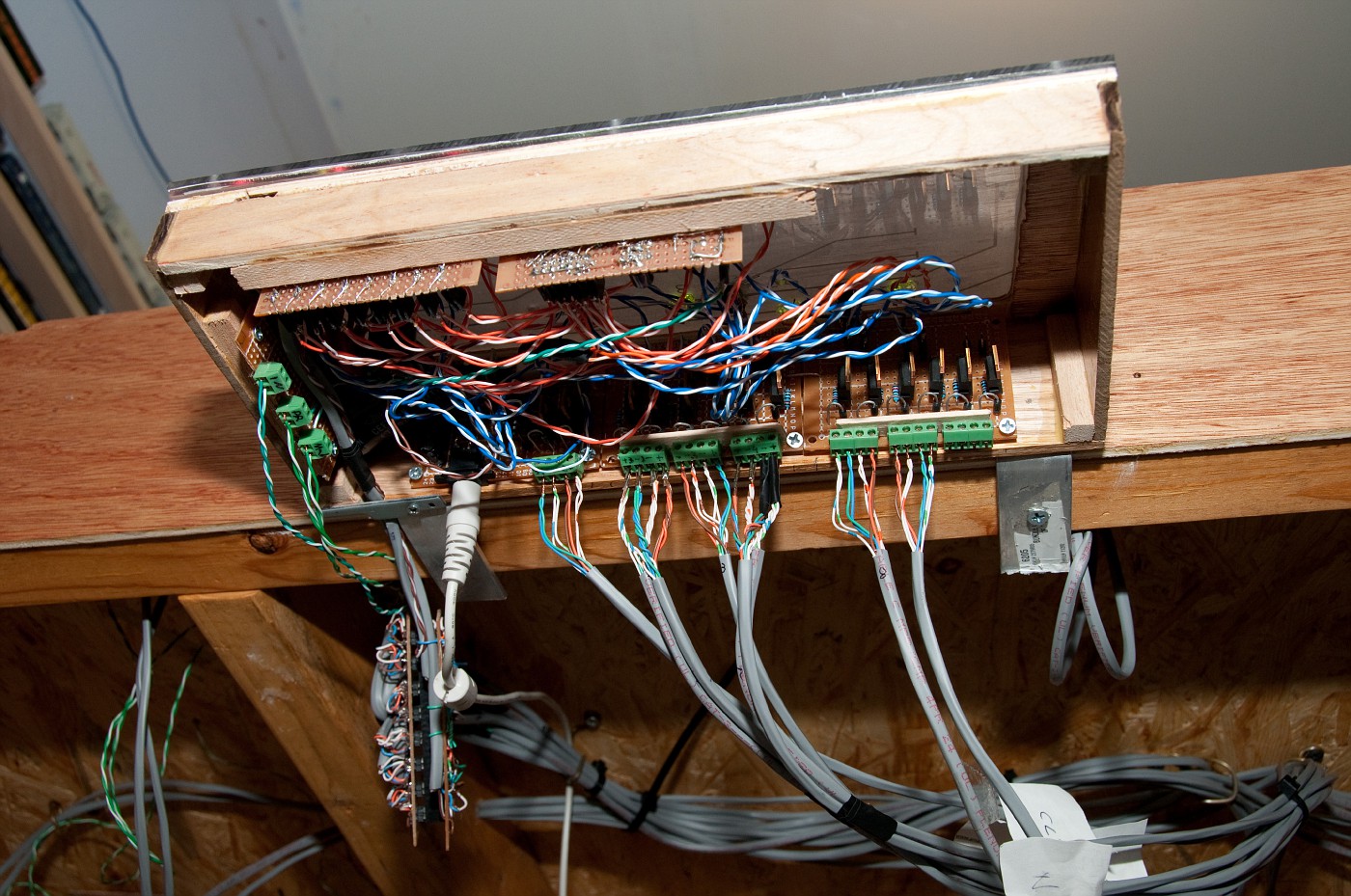

the 3 solenoid driver circuits are finished and consolidated into 1 device. added additional capacitor to consistently throw paired turnouts (one channel driving 2 coils)

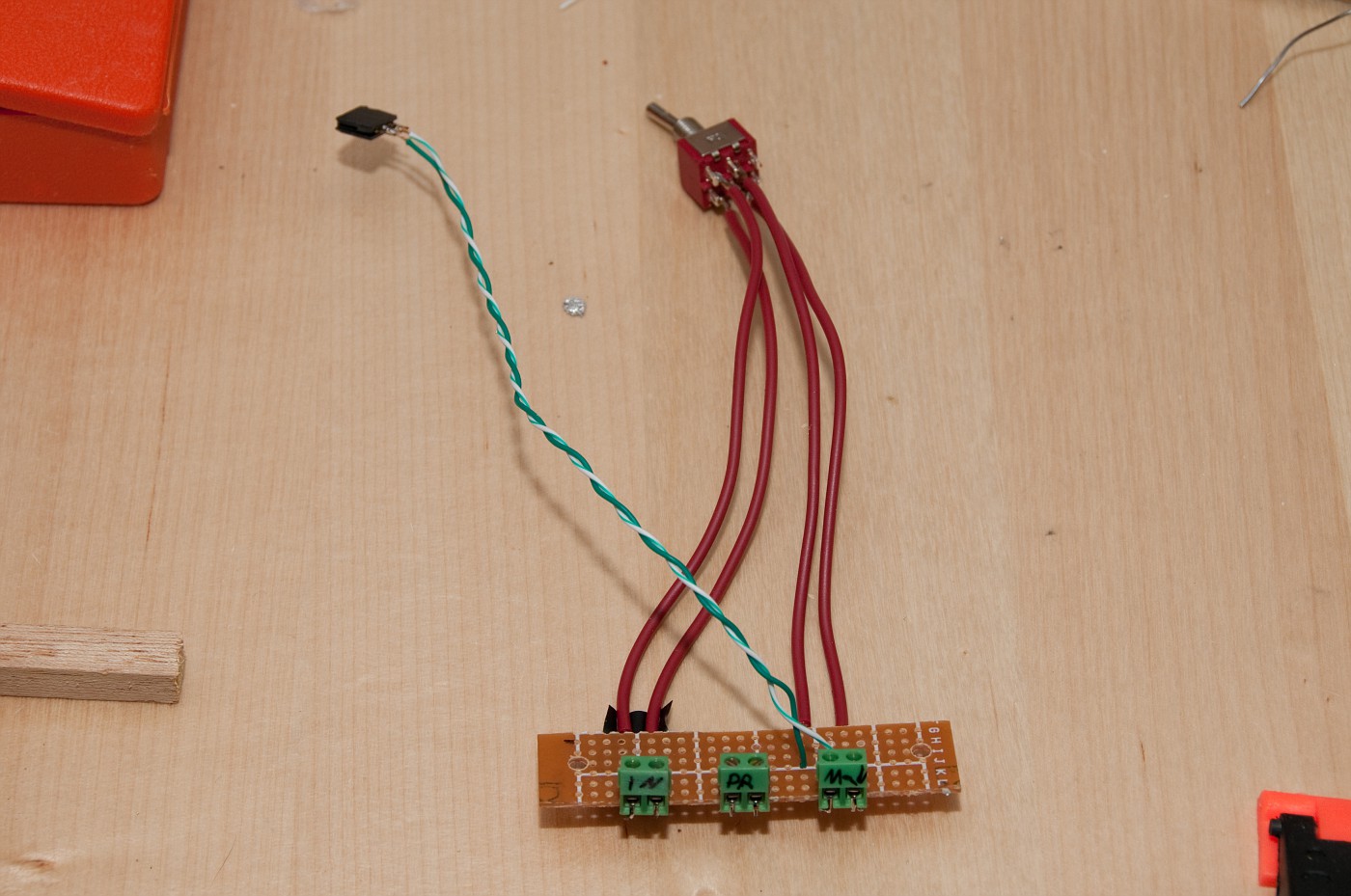

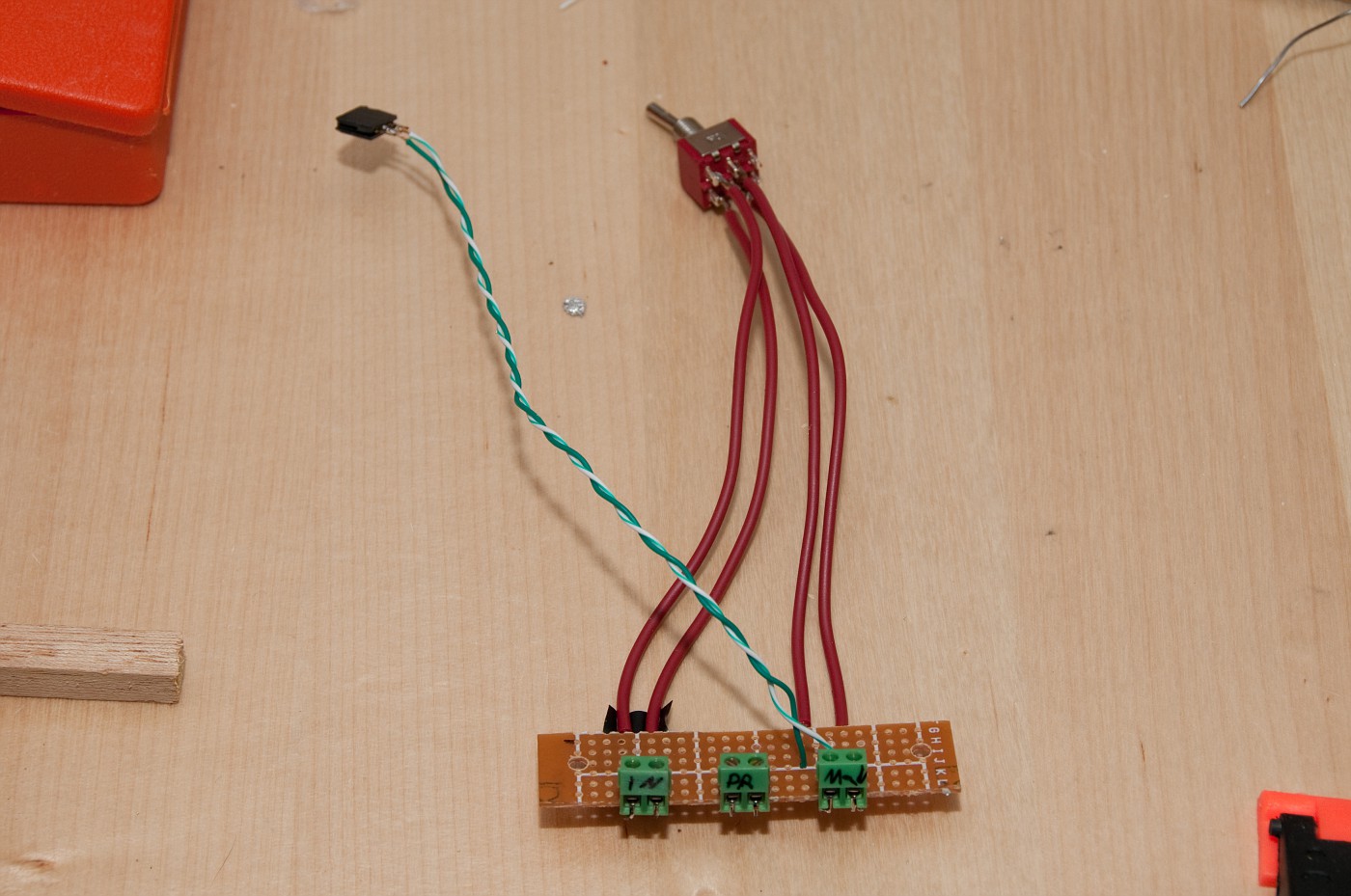

program track circuit. the turnout indication is powered from the "run" side. this way when switch set to "program" there no illumination but the red LED of the powercab base.

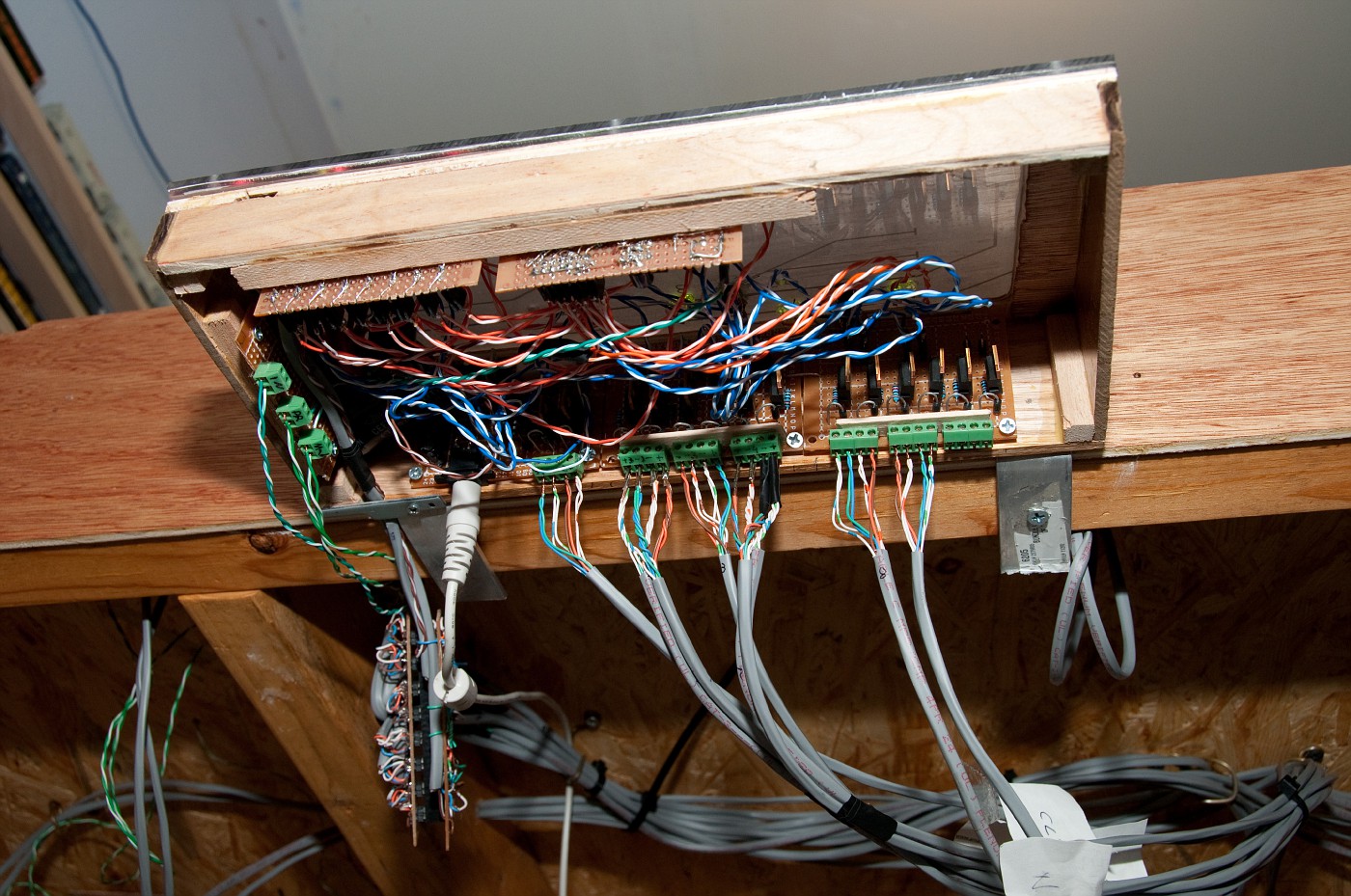

all came together. and the real surprising thing it all works!

little wire management will be done later

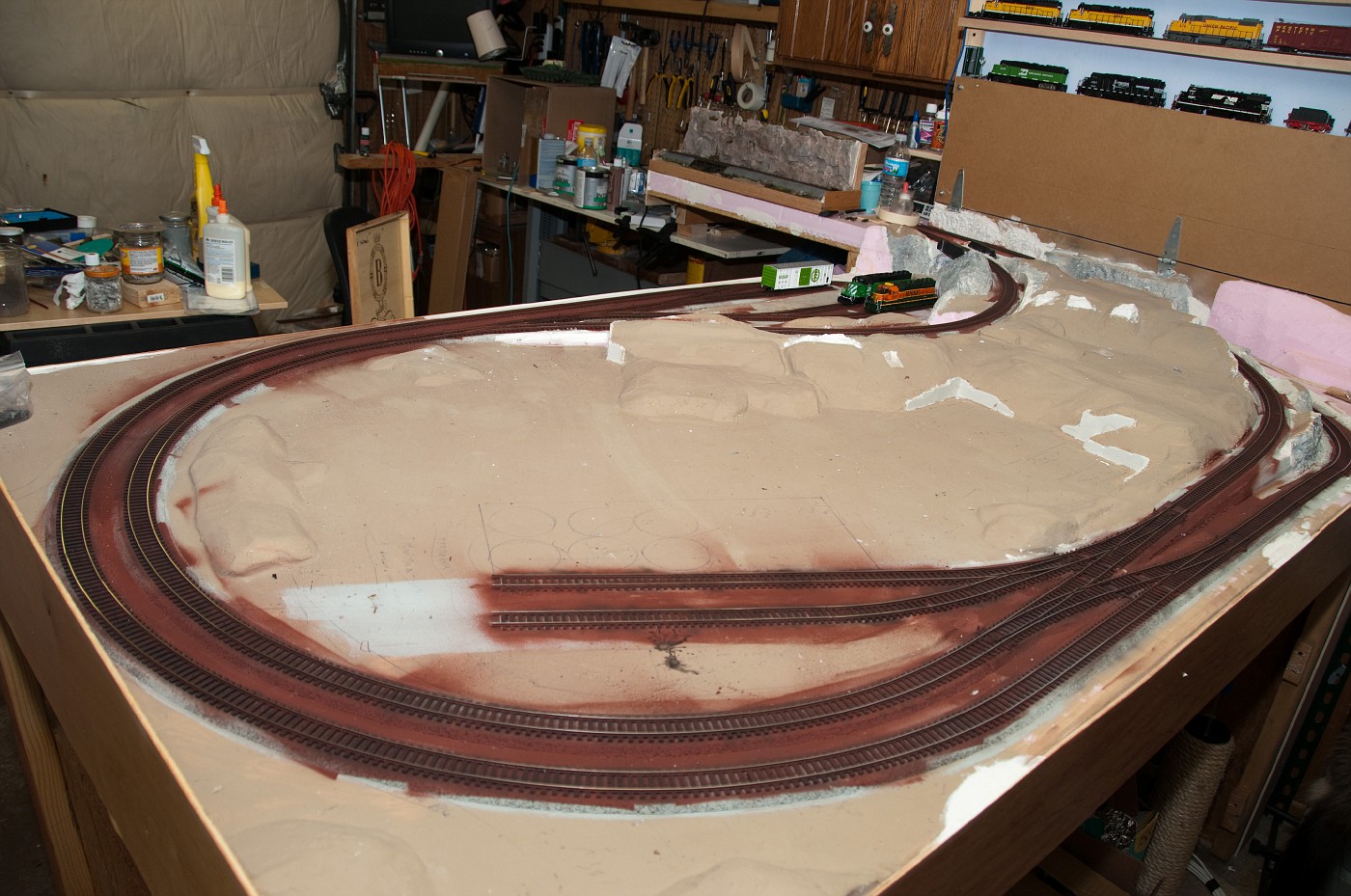

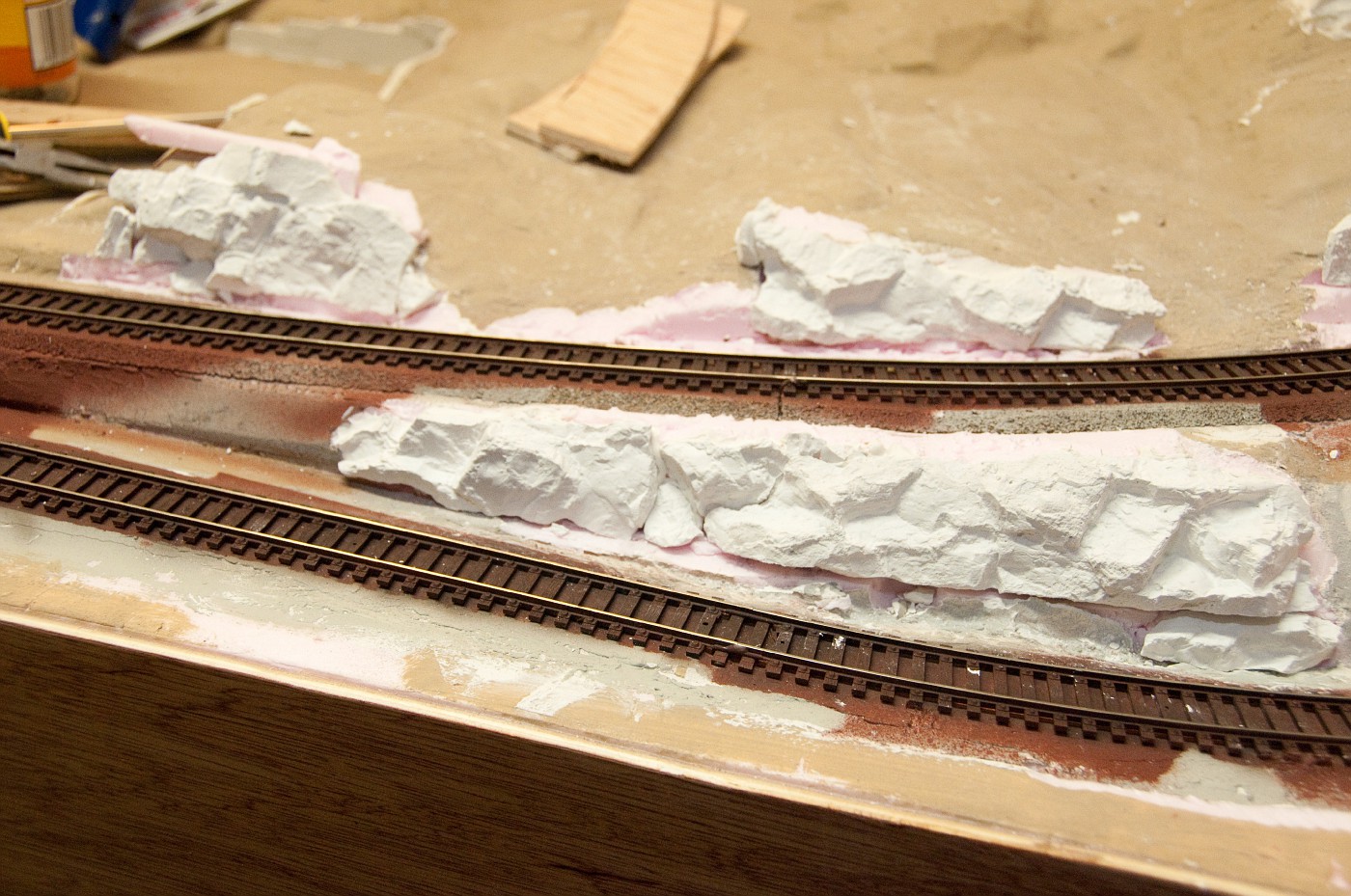

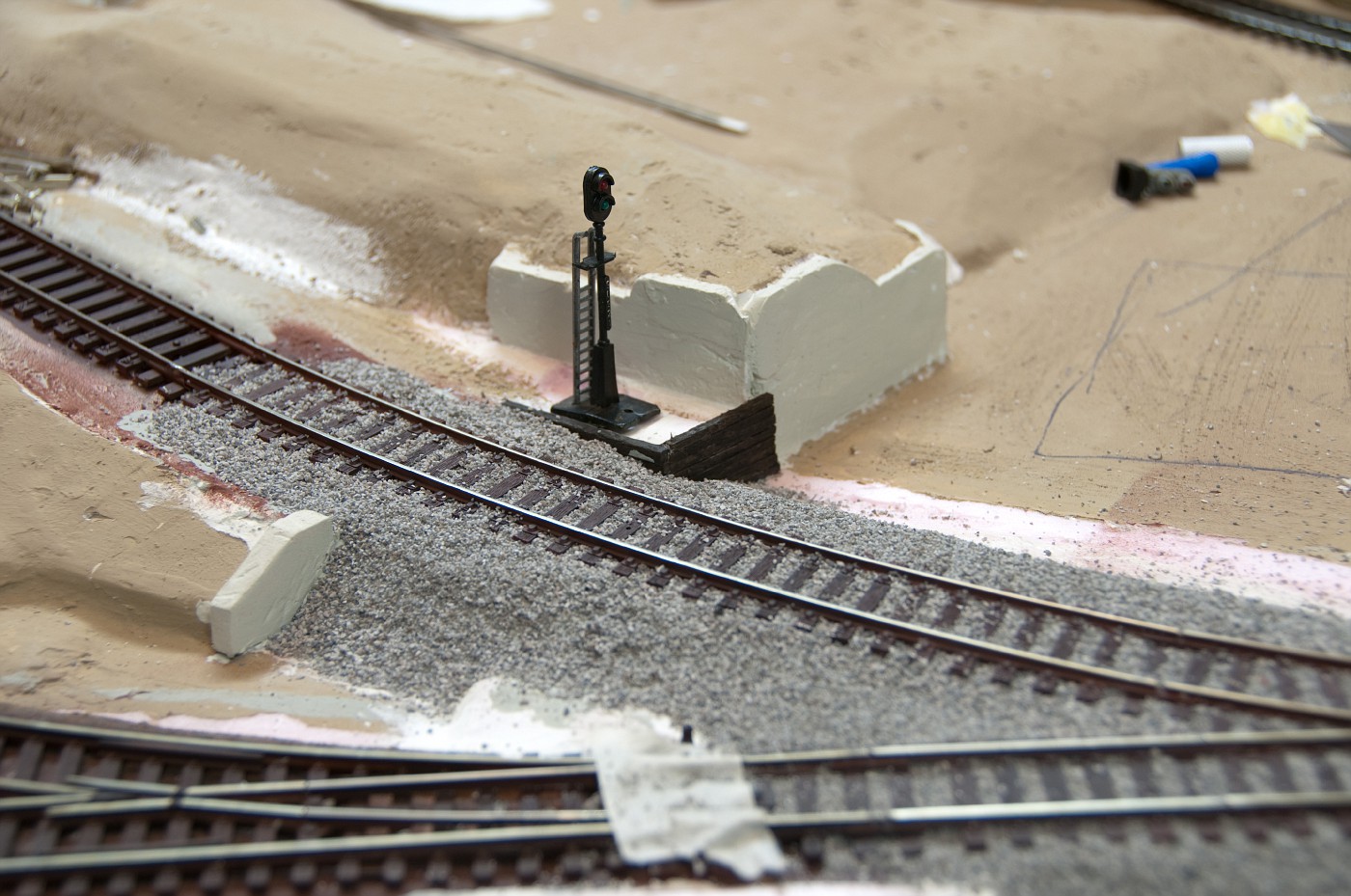

now with electronics out of the way its scenery time

the 3 solenoid driver circuits are finished and consolidated into 1 device. added additional capacitor to consistently throw paired turnouts (one channel driving 2 coils)

program track circuit. the turnout indication is powered from the "run" side. this way when switch set to "program" there no illumination but the red LED of the powercab base.

all came together. and the real surprising thing it all works!

little wire management will be done later

now with electronics out of the way its scenery time

Last edited by a moderator: