I have been building my layout with the Fast Tracks system for about a year now.

I thought I would write a little review of the Fast Tracks products I am using.

To start with I use the straight main line jig, the #4 turnout jig, the #6 turnout jig and the #8 turnout jig.

I also have 2 curve jigs from 20" radius to 30" radius in 2" increments. 6 different radii in all.

To go with the turnout jigs I have all the filing jigs. The Frog and point jig for each and a jig for filing the stock rail away for the points.

I will say that all of the products I have from Fast Tracks are very high quality and well made.

All are fairly simple to use. No hoops to jump through or holding your mouth just right to get them to work.

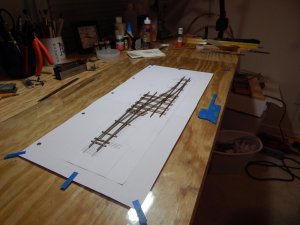

The finished product looks good and works well.

The turnouts are almost flawless. This depends on how you build them. If you take your time and try to do a neat job they do work well.

The turnouts are not difficult to make. It does take a little practice and some understanding of what your are doing.

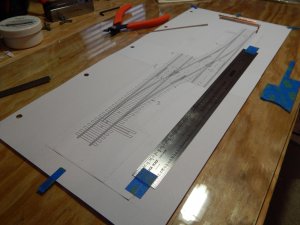

The turnout jigs have all the bends you need to make on the jig. There is not any real measuring to do.

I think when finished the track looks and performs better than sectional track that I have seen and used.

The only problem I have found is the cost.

I have about $1,000.00 in Fast Tracks so far.

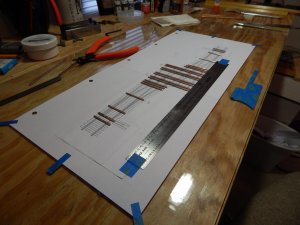

You do have to buy solder, PCB ties and glue from Fast Tracks.

I use their ties for turnouts and curves. I use regular hand laid ties for the straights.

I have found way better prices on rail.

Over all, building my own track is fun and entertaining. I have learned a great deal about model railroad track doing it this way.

I now understand a turnout better and a diamond crossing.

I would not recommend this to anyone on a tight budget. You will never recoup your cost for the jigs no matter how much track you lay.

I thought I would write a little review of the Fast Tracks products I am using.

To start with I use the straight main line jig, the #4 turnout jig, the #6 turnout jig and the #8 turnout jig.

I also have 2 curve jigs from 20" radius to 30" radius in 2" increments. 6 different radii in all.

To go with the turnout jigs I have all the filing jigs. The Frog and point jig for each and a jig for filing the stock rail away for the points.

I will say that all of the products I have from Fast Tracks are very high quality and well made.

All are fairly simple to use. No hoops to jump through or holding your mouth just right to get them to work.

The finished product looks good and works well.

The turnouts are almost flawless. This depends on how you build them. If you take your time and try to do a neat job they do work well.

The turnouts are not difficult to make. It does take a little practice and some understanding of what your are doing.

The turnout jigs have all the bends you need to make on the jig. There is not any real measuring to do.

I think when finished the track looks and performs better than sectional track that I have seen and used.

The only problem I have found is the cost.

I have about $1,000.00 in Fast Tracks so far.

You do have to buy solder, PCB ties and glue from Fast Tracks.

I use their ties for turnouts and curves. I use regular hand laid ties for the straights.

I have found way better prices on rail.

Over all, building my own track is fun and entertaining. I have learned a great deal about model railroad track doing it this way.

I now understand a turnout better and a diamond crossing.

I would not recommend this to anyone on a tight budget. You will never recoup your cost for the jigs no matter how much track you lay.