Rabman

Active Member

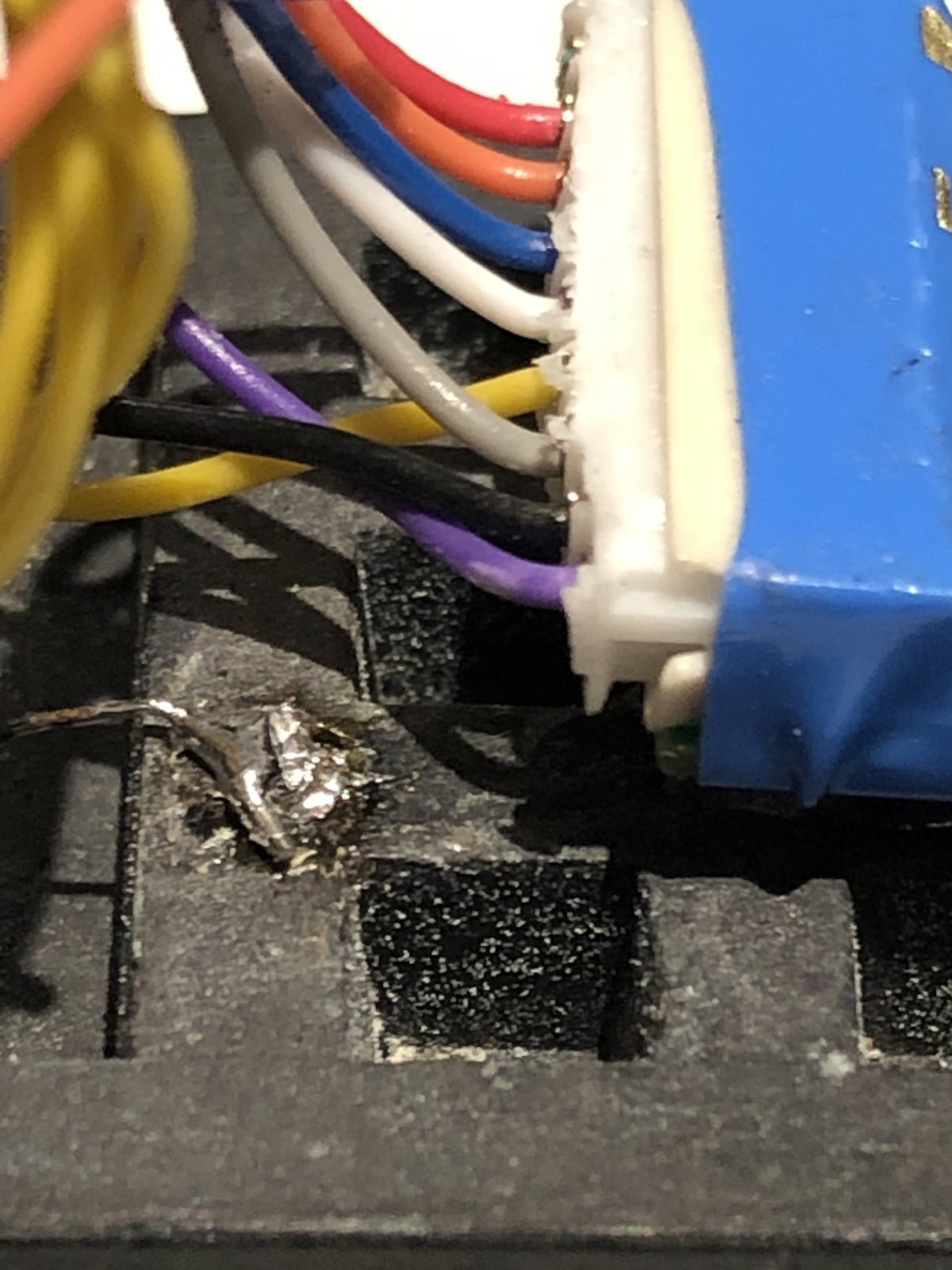

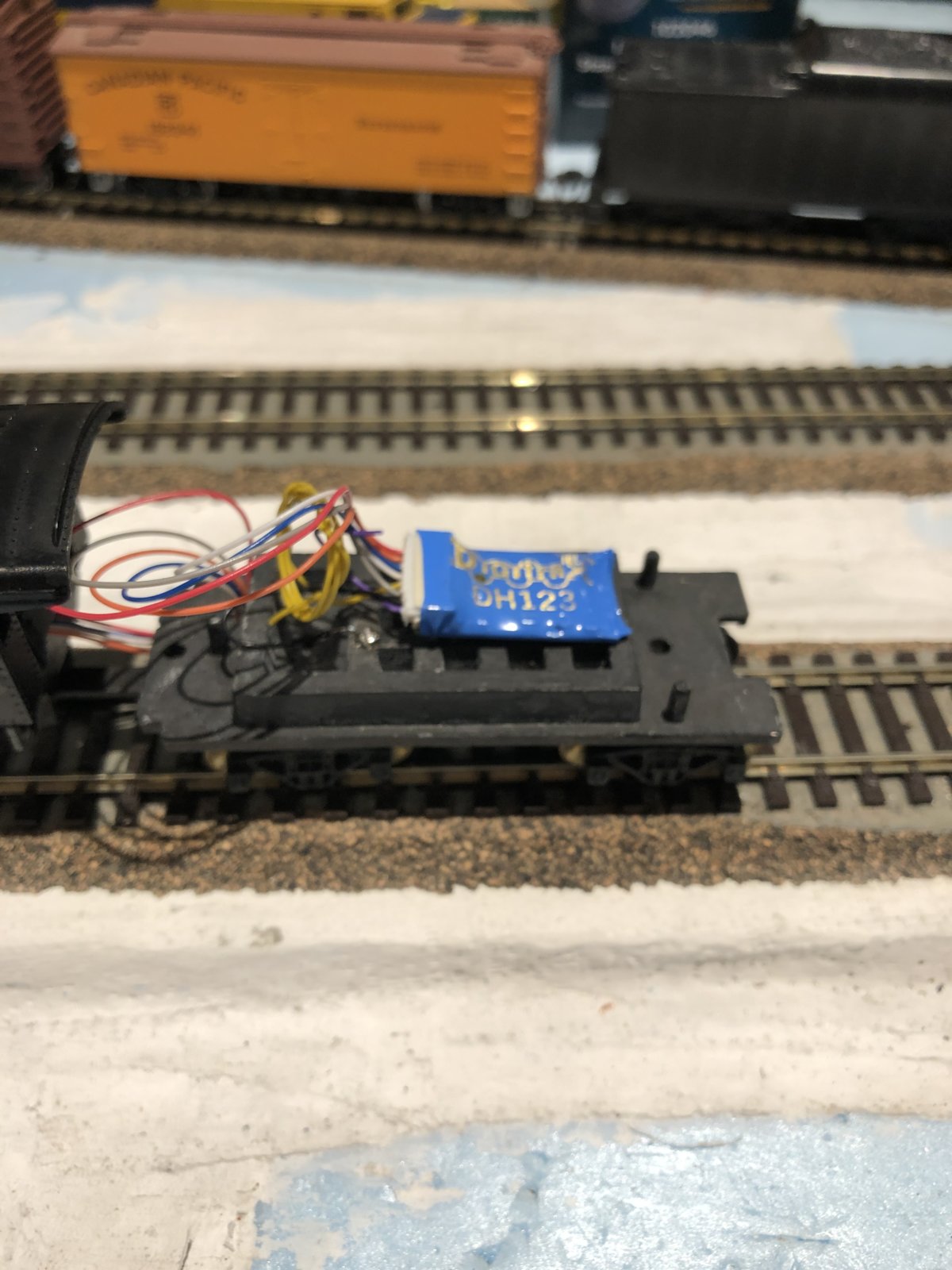

I installed a DCC Decoder in my old 0-4-0 Mantua locomotive.

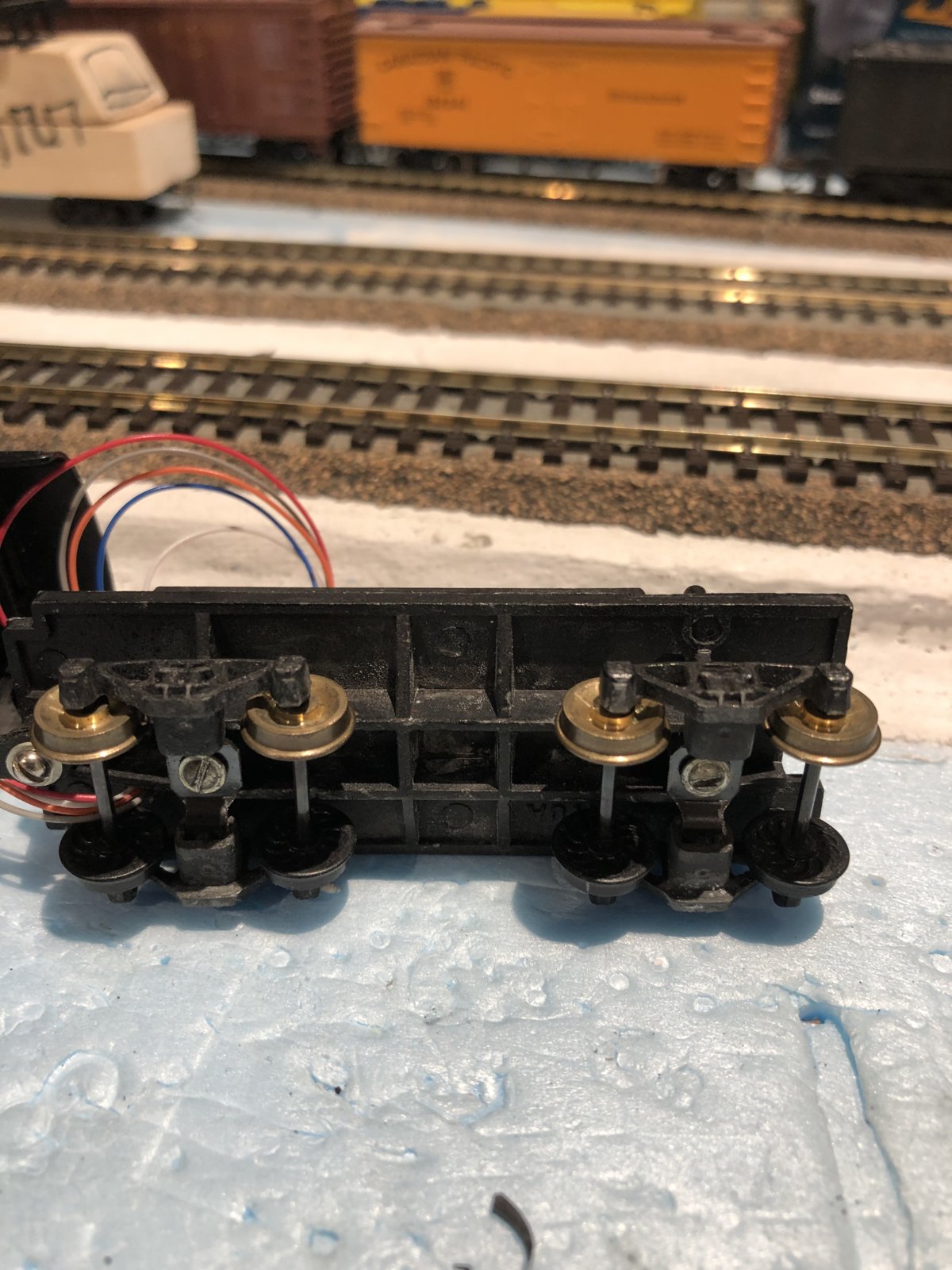

The loco picks up rail voltage from the tender through the frame.

It is not working well as it is. I cleaned the wheels and connections points on the frame and truck frame. Didn’t clean at the ends of the axles as yet.

I did drill a hole in the frame at the top and stuck solder and the wire into it the better the connection to the frame.

I am wondering if there is a conductive grease I can put in the interface of the fram to top of truck frame to increase the conductivity.

I tried graphite powder and it didn’t seem to work.

Any thoughts other than replacing the trucks?

It works well when I jumper the power from the rail to the dcc Decoder black wire.

The loco picks up rail voltage from the tender through the frame.

It is not working well as it is. I cleaned the wheels and connections points on the frame and truck frame. Didn’t clean at the ends of the axles as yet.

I did drill a hole in the frame at the top and stuck solder and the wire into it the better the connection to the frame.

I am wondering if there is a conductive grease I can put in the interface of the fram to top of truck frame to increase the conductivity.

I tried graphite powder and it didn’t seem to work.

Any thoughts other than replacing the trucks?

It works well when I jumper the power from the rail to the dcc Decoder black wire.

Last edited: