You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

COAL TRAINS! Everything you need to know to model them.

- Thread starter djstrains

- Start date

There are several different types of coal trains as far as make up goes.

Coal trains can be made up of cars owned by the utility (not the mine), cars leased by the utility, railroad owned cars or a mix of those. Modern unit coal trains typically are a set size for a particular utility. Privately owned or leased coal cars only operate between the owning/leasing utility plants and the mines that supply their coal. Railroad owned sets can serve more than one mine or utility. The railroad does NOT own the coal in the cars. If the utility or mine can't take a coal train (due to something wrong at the utility or mine) the railroad will work with the utility or mine to divert the coal train to a different mine or utility in the utility or mine's network or if that doesn't work they will work with the utility to divert the empties to a different mine or sell the coal to a different utility. If all that fails then the railroad has to park the coal train until the mine or utility can take it.

Different mines produce different coal, and certain utilities only burn a certain type of coal. Utilities will often mix coal from different areas and mines to get the right (or a minimum) BTU count or emissions level. A lot of eastern utilities will mix Powder River, WY coal with eastern coal to lower the sulphur emissions. Western utilities would also mix Illinios or Colorado coal with Powder River coal.

- All rotary gon - must be unloaded by a rotary dumper, must have the rotary ends aligned.

- Mixed rotary hoppers and gons - all cars must be rotary equipped (not all hoppers are rotary equipped) and the rotary ends aligned. Must be rotary dumped.

- All automatic dump hoppers - all hopper cars with an air operated dump doors, may also be rotary equipped. Will be dumped on a trestle with automatic dump controls with air operated dump doors opening and closing the doors.

- All "steel" hoppers with manual doors - all cars are bottom unloaded and the doors must be manually opened and closed. Fairly rare as a unit train anymore.

- Single car detached - the oldest method, the cars are spotted one by one in the dumper and uncoupled from the rest of the cars and are rotated by them selves. This can be used with any type of car and requires no rotary couplers.

- Coupled in train locomotive spotted - the locomotives are used to spot the cars in the dumper and the cars remain coupled together while being dumped.

- Coupled in train indexer spotted - an indexing arm is used to pull/push the cars through the dumper and the cars remain coupled together while being dumped. Newer plants use this type of system.

Coal trains can be made up of cars owned by the utility (not the mine), cars leased by the utility, railroad owned cars or a mix of those. Modern unit coal trains typically are a set size for a particular utility. Privately owned or leased coal cars only operate between the owning/leasing utility plants and the mines that supply their coal. Railroad owned sets can serve more than one mine or utility. The railroad does NOT own the coal in the cars. If the utility or mine can't take a coal train (due to something wrong at the utility or mine) the railroad will work with the utility or mine to divert the coal train to a different mine or utility in the utility or mine's network or if that doesn't work they will work with the utility to divert the empties to a different mine or sell the coal to a different utility. If all that fails then the railroad has to park the coal train until the mine or utility can take it.

Different mines produce different coal, and certain utilities only burn a certain type of coal. Utilities will often mix coal from different areas and mines to get the right (or a minimum) BTU count or emissions level. A lot of eastern utilities will mix Powder River, WY coal with eastern coal to lower the sulphur emissions. Western utilities would also mix Illinios or Colorado coal with Powder River coal.

trailrider

Well-Known Member

Since I model the 1940's - '50's. I don't have a rotary dumper. Hopper cars are "loaded" at the mine in "Southern Illinois" and assembled at the Galesburg yard, before being hauled uphill to the coal-fired electric plant "out West somewhere". They are parked behind the plant, to be rolled downhill, through a tunnel so they come out at the mine again. As the only way to unload them would be to pry the loads out of the hopper, I have a duplicate set of empties which can be pushed uphill to come out at the siding behind the electric plant. They are then picked up to return to the mine's siding. This isn't too difficult as each string of cars has only eight hoppers, about all I can fit on my layout's sidings!

Rico

BN Modeller

Trail rider that sounds like a awesome setup for operations! I’m planning something similar if/when the time comes.

DJ and Dave that’s some great info th have, thanx!

When I worked at a coal fired plant we started with lignite coal from Saskatchewan which is lower grade then switched up to bituminous coal from powder river. It was like going from burning mud to burning rocket fuel!

After head office ordered the very first 113 car train of Burlington Northern hoppers I asked them if they were bottom dump or rotary dump and they said they didn’t know. Thankfully they were bottom dump as we didn’t have a rotary dumper!

Here’s a little video of our shaker house:

I still remember that coal is made up of: nitrogen, oxygen, carbon, ash, sulpher, and hydrogen.

(NO CASH)

DJ and Dave that’s some great info th have, thanx!

When I worked at a coal fired plant we started with lignite coal from Saskatchewan which is lower grade then switched up to bituminous coal from powder river. It was like going from burning mud to burning rocket fuel!

After head office ordered the very first 113 car train of Burlington Northern hoppers I asked them if they were bottom dump or rotary dump and they said they didn’t know. Thankfully they were bottom dump as we didn’t have a rotary dumper!

Here’s a little video of our shaker house:

I still remember that coal is made up of: nitrogen, oxygen, carbon, ash, sulpher, and hydrogen.

(NO CASH)

CambriaArea51

Well-Known Member

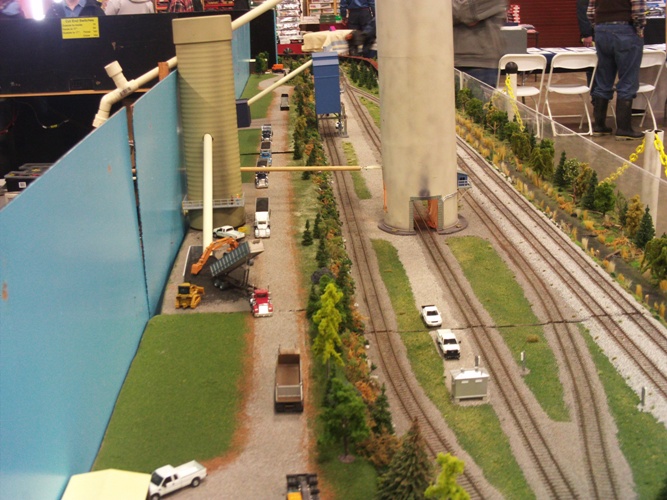

Great info,I often wondered about the different car types in a consist. This is the one that I have as a club layout (we travel). Air assist loads the coal into the flood loader. I can do about 25-28 cars. I'll run 50 to 70 cars depending on the layout size. I'll add pushers for show also which draws a crowd at a show.