Or.....you could wait till they all come round with their trains and say, "There's some wiring I want you to help me with before you run your trains".Back to the bridge construction.

I've been fiddling with the Digitrax system to determine why the difficulties occured during the last op session.

I found that I had the repeaters set up wrong. Two of the power management boards, PM42 had the same address.

I also decided to get rid of the pile of PS14 power supplies (wall warts) and use centrally located power supplies to power the signal and power management boards. One power supply for each type of board. Also, I don't need to have any of the PM42s on the loconet. This is taking longer to accomplish than I anticipated along with the reels of wire I using up for this.

I want to do an open house the Saturday after Christmas for club members to bring their new toys to run. I'll have a better idea if I can do that by tomorrow night depending on how much wiring I can finish before I break for Monday Night Football.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Canyon Diablo Bridge

- Thread starter D&J RailRoad

- Start date

D&J RailRoad

Professor of HO

I don't think I want to try that. I would end up with 10 different ways to fix the wiring.

Would end up like my club's layout. I got asked by the main electrician one day, if I had done any mods to the wiring behind a control panel. I told him I wouldn't even dare to open it up.I don't think I want to try that. I would end up with 10 different ways to fix the wiring.

D&J RailRoad

Professor of HO

Uh ohhhhh.

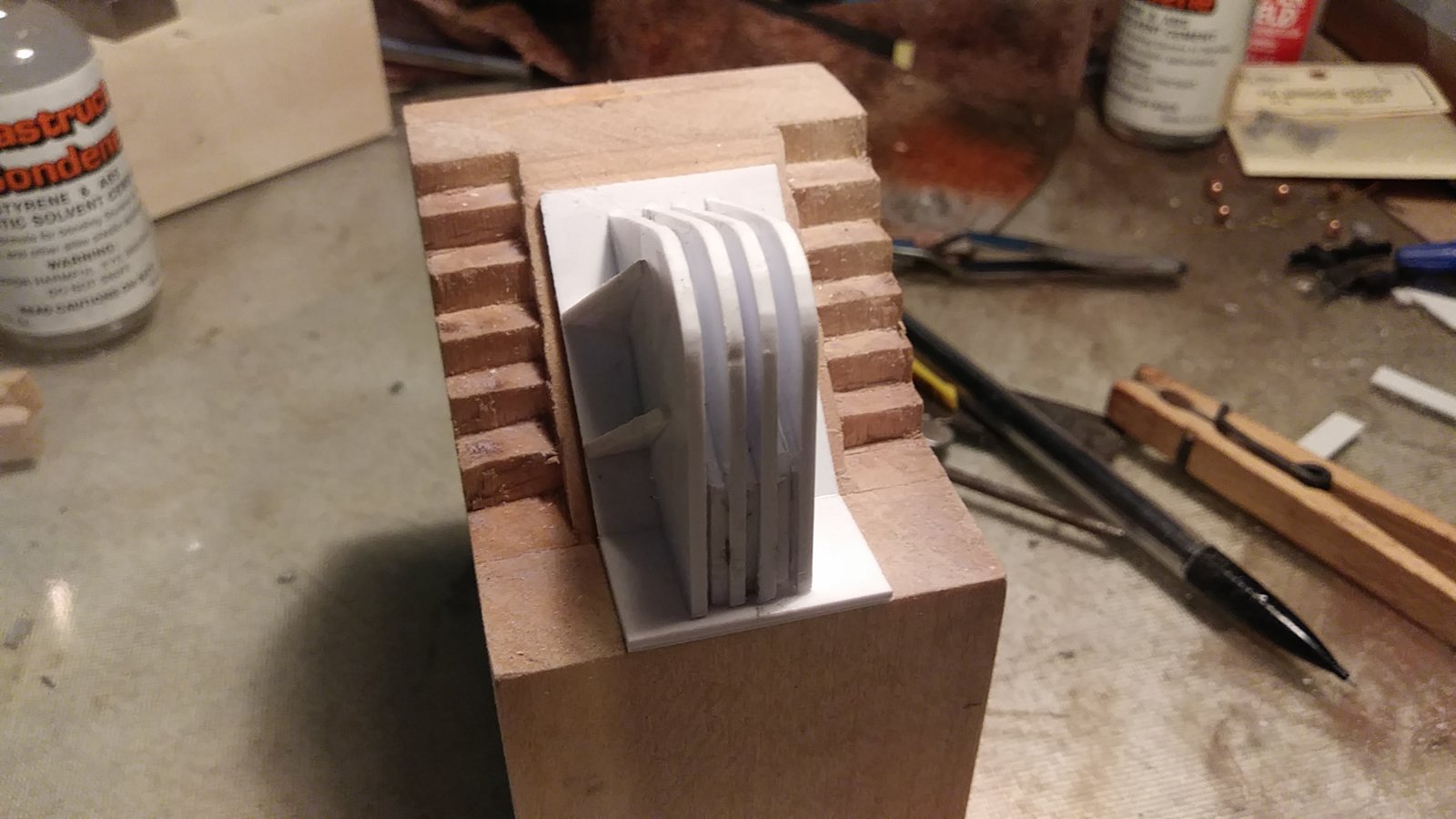

This is the one that the wood core was stuck in. Apparently the wood expanded.

I'll have to pour another one.

I pulled the wood core out and then put the piece in a vice to try to bend it to close the crack but it broke completely.

This is the one that the wood core was stuck in. Apparently the wood expanded.

I'll have to pour another one.

I pulled the wood core out and then put the piece in a vice to try to bend it to close the crack but it broke completely.

Last edited:

flyboy2610

Loveably weird

Oh, Pooh.

D&J RailRoad

Professor of HO

I had the plaster stuff on hand and the mold was sitting up on the shelf. It's already poured and setting up. Should be ready to pop out of the mold in the morning.

I'm hosting another op session this Saturday for the club members to bring their new train toys to run on the layout. Things are pretty well cleaned up now. Just gotta unclutter the desk.

I'm hosting another op session this Saturday for the club members to bring their new train toys to run on the layout. Things are pretty well cleaned up now. Just gotta unclutter the desk.

Uh ohhhhh.

This is the one that the wood core was stuck in. Apparently the wood expanded.

I'll have to pour another one.

I pulled the wood core out and then put the piece in a vice to try to bend it to close the crack but it broke completely.

Looks like typical Cal Trans Roadwork to me?

Alcomotive

Grandson of an ALCO Builder

I would salvage it or something to use as abandon....repaired/replace etc. It looks cool! Sorry about that but....don't toss it...

D&J RailRoad

Professor of HO

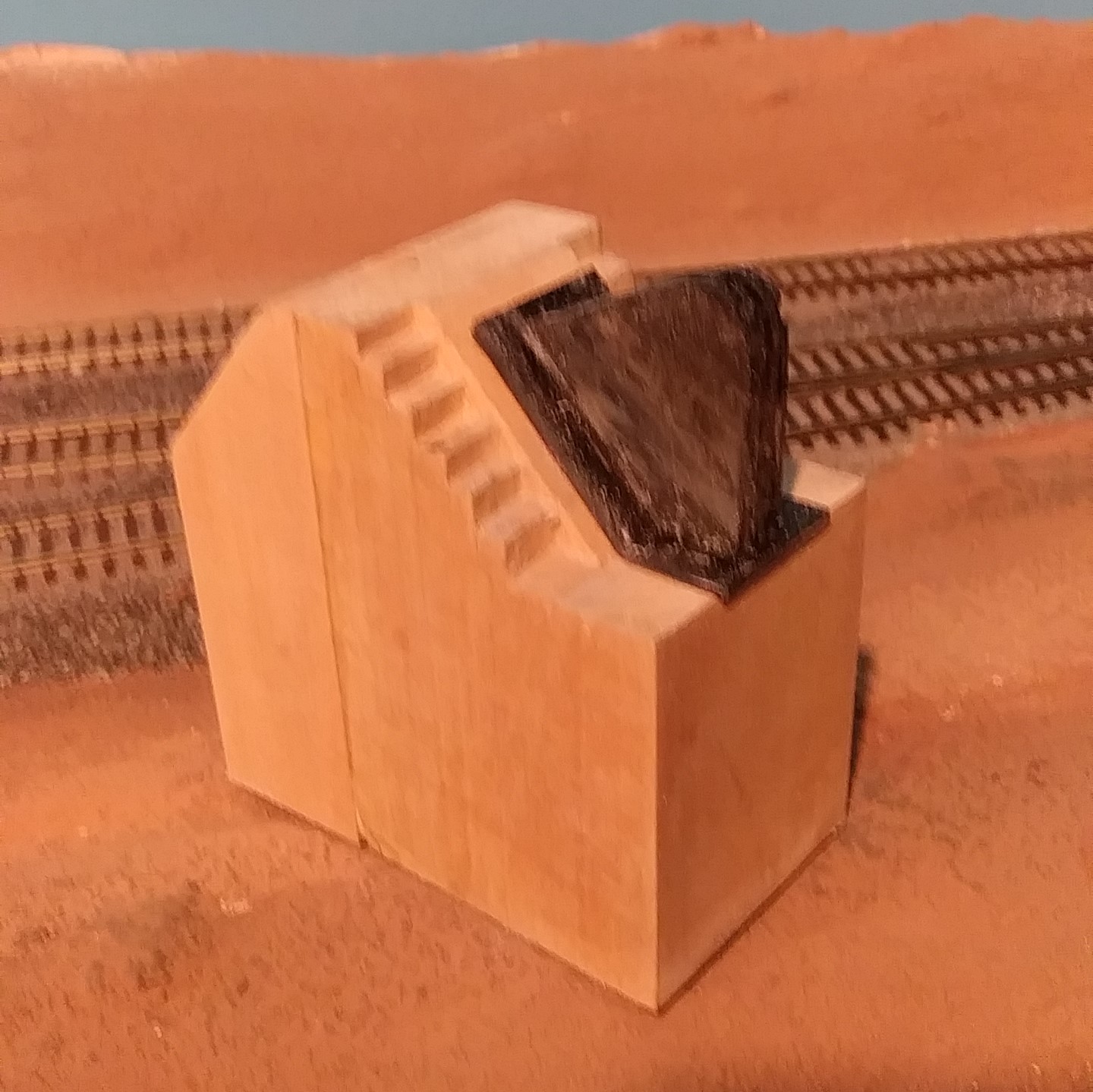

The new one has cured and looks great.

D&J RailRoad

Professor of HO

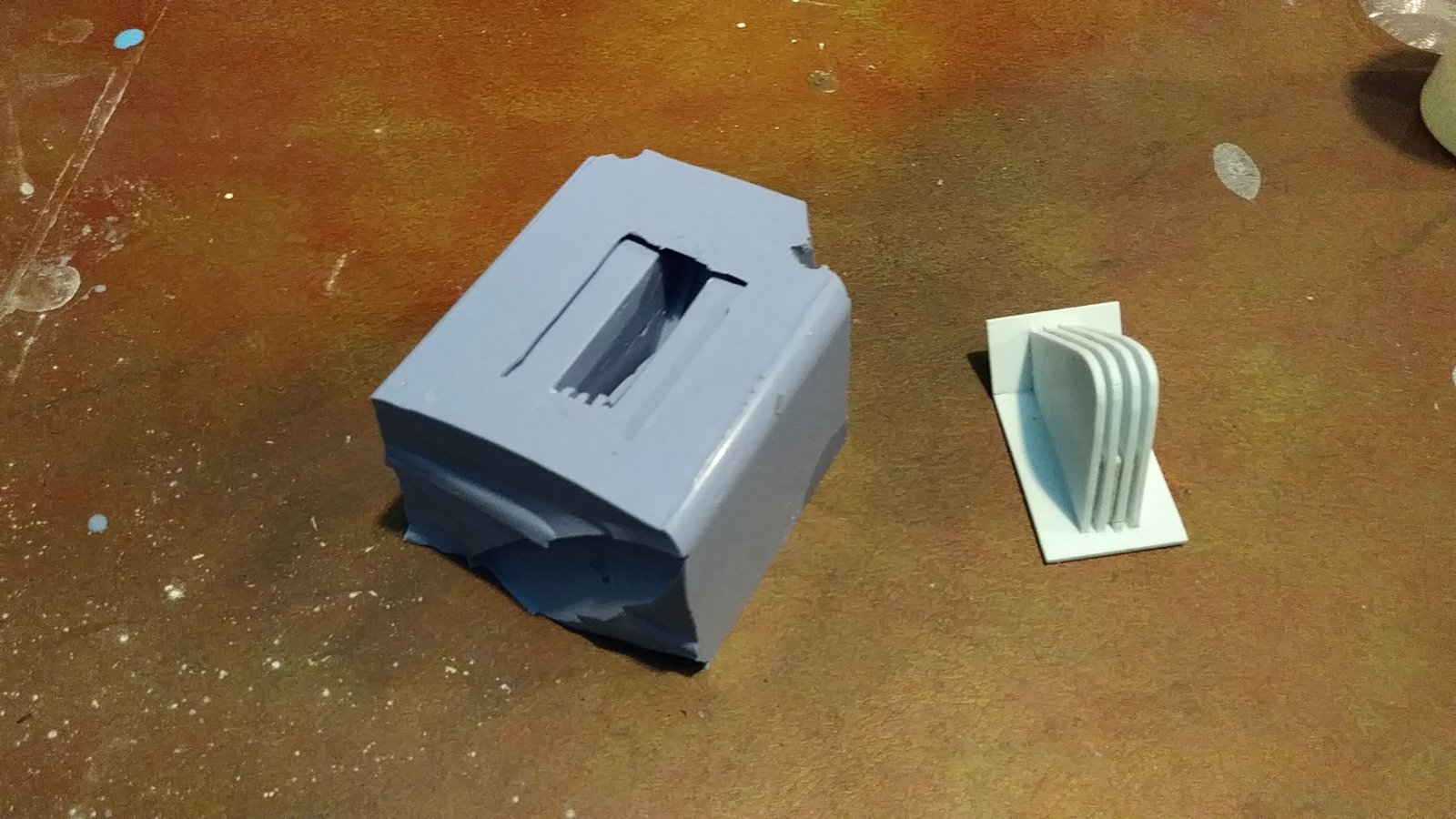

I finished making the bearing shoe and made a sillicon mold. I mixed a batch of the plastic resin and poured it in then let it set for a couple hours. A little difficulty separating it from the mold despite the separating agent that I applied before pouring the resin. That's when I realized I hadn't applied the side braces to the shoe. Anyway, I spray painted the bearing shoe flat black, let it dry then set it on the concrete footer to see how it looked. Looks good but somehow the cloned copy is a little bigger than the original and it hangs over the front edge of the footer. I think it might be easier to remake the concrete footer.

Last edited:

D&J RailRoad

Professor of HO

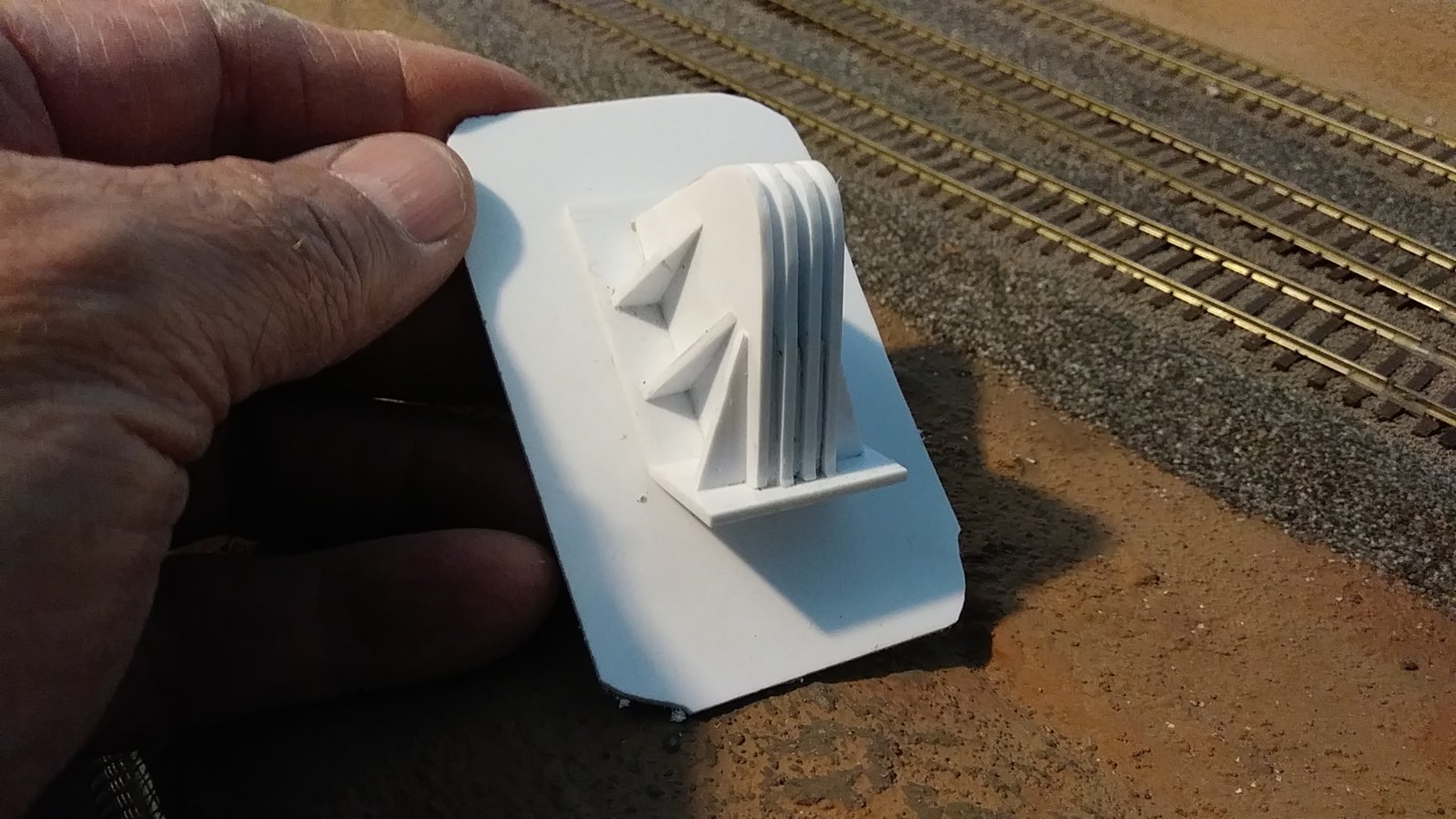

I finished the side supports to the bearing shoe. I'll have to wait till I get back from Michigan next week to make the mold.

D&J RailRoad

Professor of HO

Just discovered another set back. As you can see the four upright members of the shoe bearing. The bridge beam is supposed to slip in between the upright pieces then a bearing bolt is supposed to go through the whole thing to keep it together as in the picture of the real shoe bearing.

I test fit the bridge beam to the shoe and it's off by quite a bit. The outside upright plates of the shoe bearing have to bend outward for the beam to slip in properly. I'll have to rebuild the shoe from scratch. This plastic one is plasti welded together and it would get to chopped up to try to cut it apart.

You can also see how much more of the concrete footer is out in front of the bearing shoe.

I test fit the bridge beam to the shoe and it's off by quite a bit. The outside upright plates of the shoe bearing have to bend outward for the beam to slip in properly. I'll have to rebuild the shoe from scratch. This plastic one is plasti welded together and it would get to chopped up to try to cut it apart.

You can also see how much more of the concrete footer is out in front of the bearing shoe.

N

NP2626

Guest

D&J Railroad, would it have been easier to build the Shoes from sheet styrene? There are four shoes, correct? Cut out the 16 upright plates, drill the holes in a jig then assemble the uprights to the bearing plates and add the side bracing? I have to say that you are the expert in this process and certainly will defer to your ideas of how to proceed. Knowing how to mold these types of details is certainly good to learn! As a former Tool and Die Maker, i understand how precisely these parts need to be made! This has been a great project to follow along with, thanks for sharing!

D&J RailRoad

Professor of HO

I've considered building each one by hand, but I'm planning for down the road as well. I might be building another bridge for a modular setup and I just might market this later on as a kit. The kit would consist of a scale size drawing like the Campbell kits, a bill of material for the plastic parts, 4 cast footers and four resin bearing shoes along with my email address to provide encouragement.

While not a solution to the current problem, your prototype photo gives an example as to the previous cracked 'concrete' one and it's repair

I've considered building each one by hand, but I'm planning for down the road as well. I might be building another bridge for a modular setup and I just might market this later on as a kit. The kit would consist of a scale size drawing like the Campbell kits, a bill of material for the plastic parts, 4 cast footers and four resin bearing shoes along with my email address to provide encouragement.

That is an ambitious plan - and I am sure that you can pull it off!

In the meantime ... can you see any progress, or is the cigar smoke too thick?

D&J RailRoad

Professor of HO

Yes on the progress. I'm going to try to just rebuild the bearing shoe and see if I can fit it onto the existing footer. Got the main part of the bearing built. Had to take a break to run some errands and take care of admin stuff.

Just have to weld the side struts onto the bearing shoe then I can make the silicon mold for it. Looking to do that this evening.

Just have to weld the side struts onto the bearing shoe then I can make the silicon mold for it. Looking to do that this evening.

D&J RailRoad

Professor of HO

Here is the updated bearing shoe before I immersed it in the silicon material. The middle slot is the same size. The slots on each side are a slight bit wider. I'll add the two strut pieces to the cast piece because they would make it hard to pull them out of the mold. The front of the real footer has the walkway going across to the other steps so this one is slightly modified from the real one.