Kylemaneti95

Active Member

Hey guys, a few months ago I had to put my historically accurate Morrison Colorado layout on the backburner, mainly because of space issues and needing to move before starting actual construction. Since then I have started a much larger project, both in terms of scale and complexity.

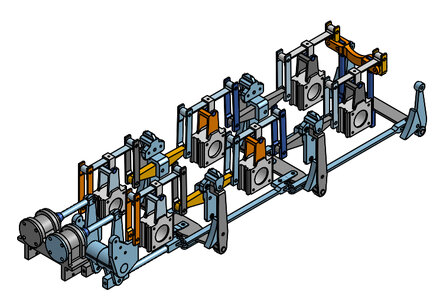

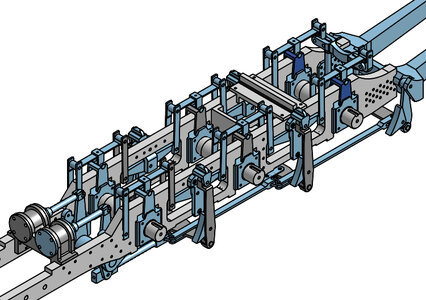

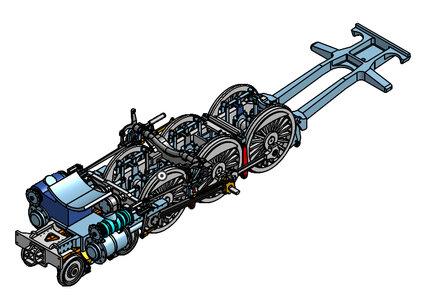

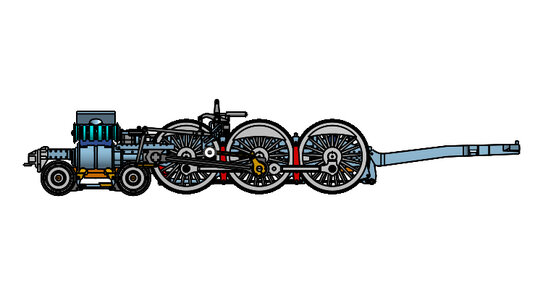

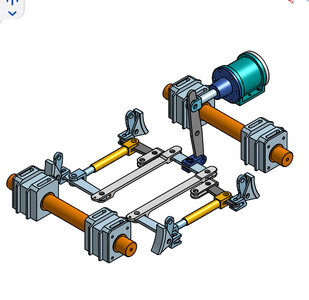

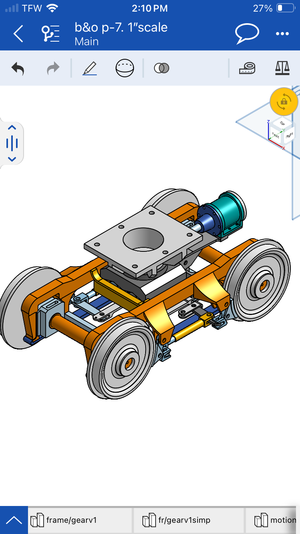

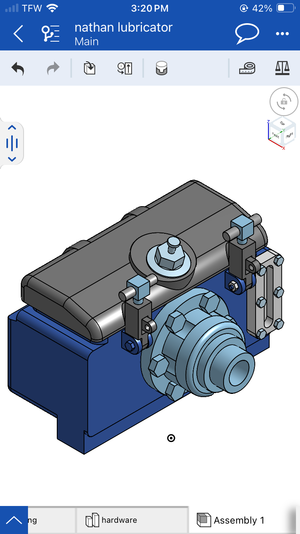

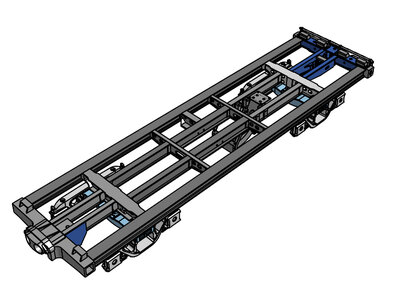

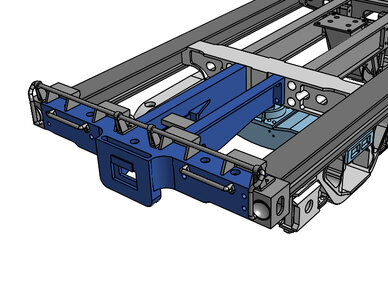

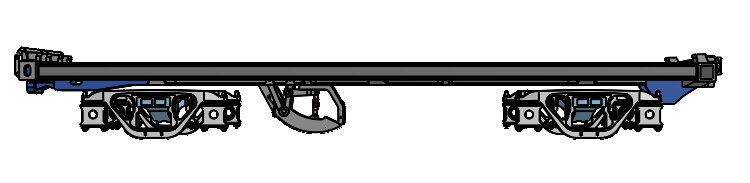

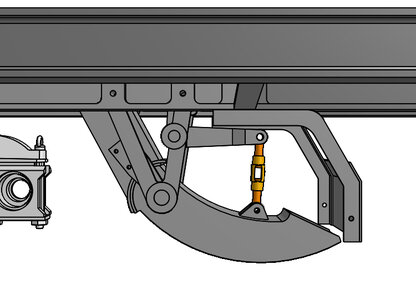

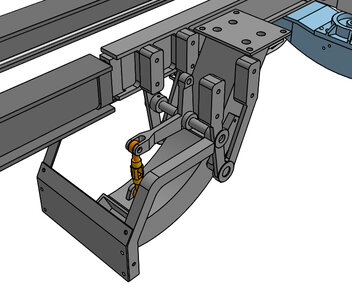

October 1st 2023 I started working on CAD models of a 1:12 scale live steam locomotive. The Baltimore and Ohio p7 class, specifically the first loco in the class #5300 “President Washington.” The drawings I am working from were done up by Doug Alkire, I’ll post a link shortly to take you to the drawing set.

I currently have over 300 parts modeled so I’m quite far into the model and will be posting some of the highlights from the last few months to show the work I’ve gotten done so far.

I have not started on anything above the frame of the locomotive or tender, but I’m getting closer everyday.

Anyway, here is a picture dump showing some of the stuff I’ve gotten done already, I hope you all enjoy

October 1st 2023 I started working on CAD models of a 1:12 scale live steam locomotive. The Baltimore and Ohio p7 class, specifically the first loco in the class #5300 “President Washington.” The drawings I am working from were done up by Doug Alkire, I’ll post a link shortly to take you to the drawing set.

I currently have over 300 parts modeled so I’m quite far into the model and will be posting some of the highlights from the last few months to show the work I’ve gotten done so far.

I have not started on anything above the frame of the locomotive or tender, but I’m getting closer everyday.

Anyway, here is a picture dump showing some of the stuff I’ve gotten done already, I hope you all enjoy