flyboy2610

Loveably weird

At the beginning of June, I bought an Athearn UP rotary plow at at train show in Omaha. I bought it at the same time I bought the Rivarossi UP greyhound observation car, which I recently finished upgrading.

Someone had "converted" this plow to run on battery power. There was a motor held to the chassis by a piece of wire, a battery box inside the car, and a switch mounted to the bottom of the chassis.

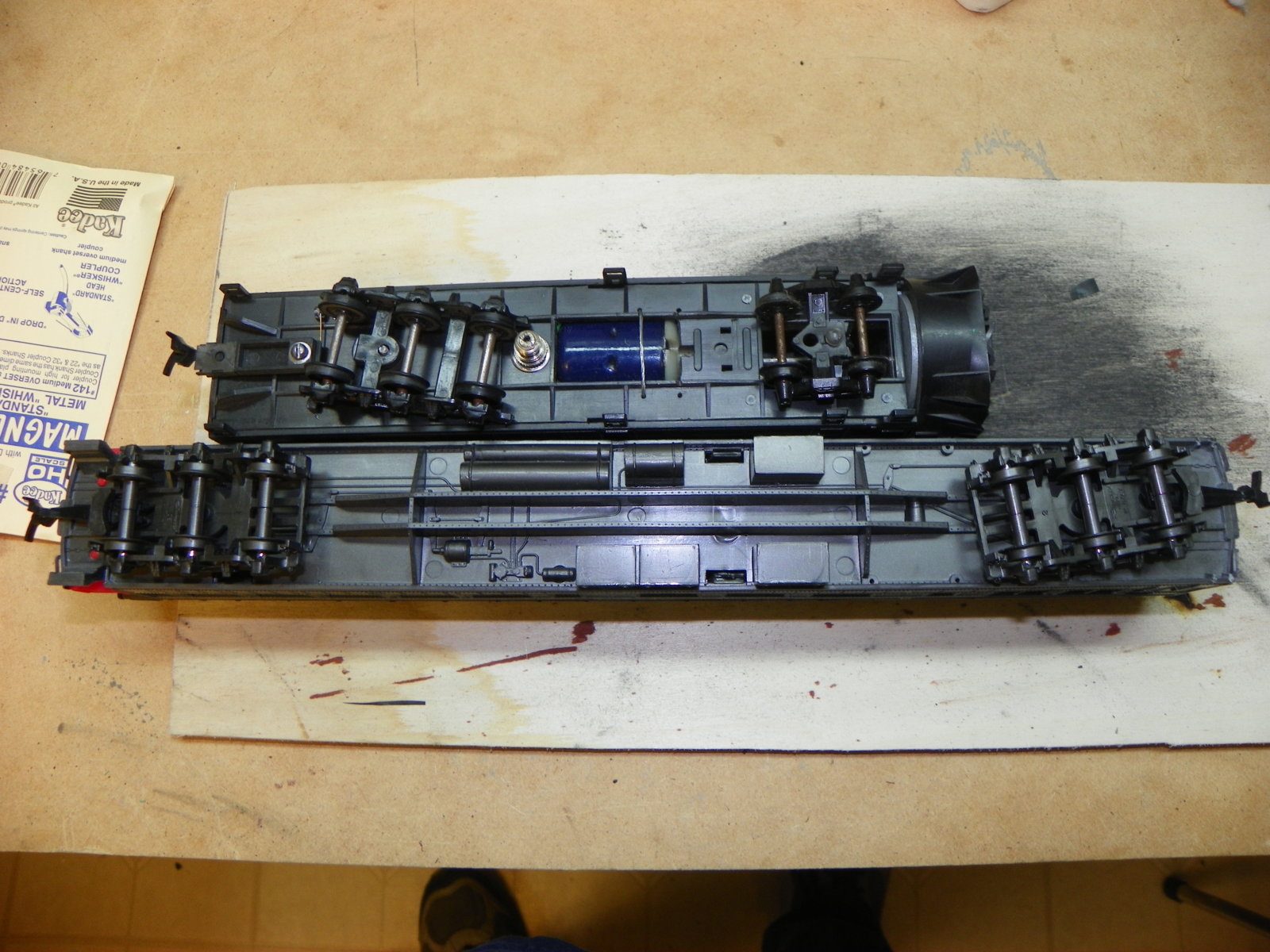

The plow is on top in this pic:

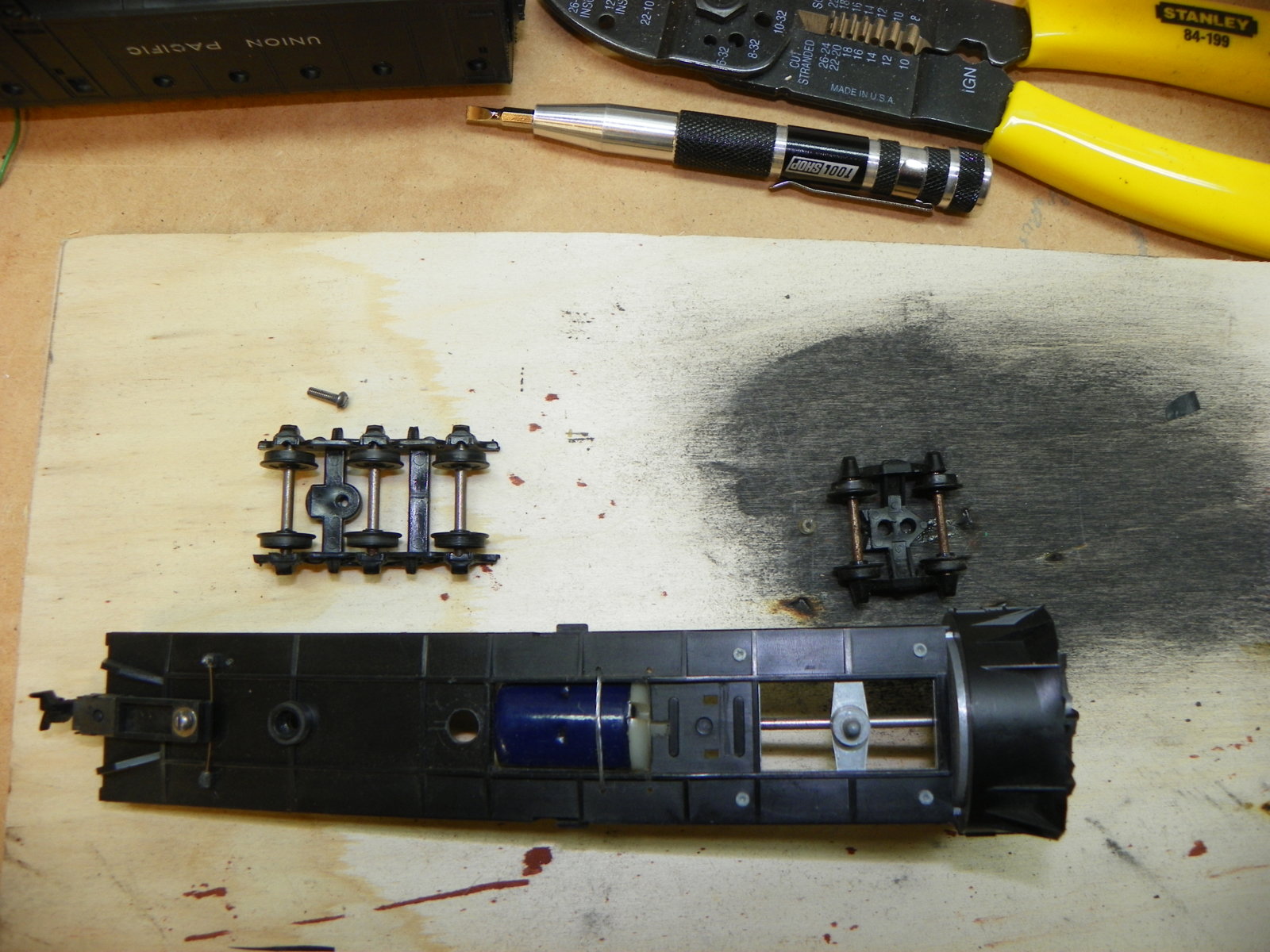

These items have since been removed. The front truck was held onto the pin by a piece of silicon tubing!

That is not the correct truck, anyway. A suitable replacement will be found for it. The prototype UP rotary plow #076 was built by Lima-Hamilton in January 1950. It was retired in June 1985. Here's a pic of it:

As you can see, the first order of business is a repaint. But first the decals have to come off. I tried removing them with a Bright Boy, but that wasn't such a bright idea. Then I found a YouTube video on removing decals. Use some toilet paper (on the model, that is) and cover the decal. Use a cotton swab and saturate the area with MicroSol, the decal solvent in a red bottle.

Wait 5 minutes for the solvent to work, the remove the tissue and use a dry cotton swab to clean the decal off the model.

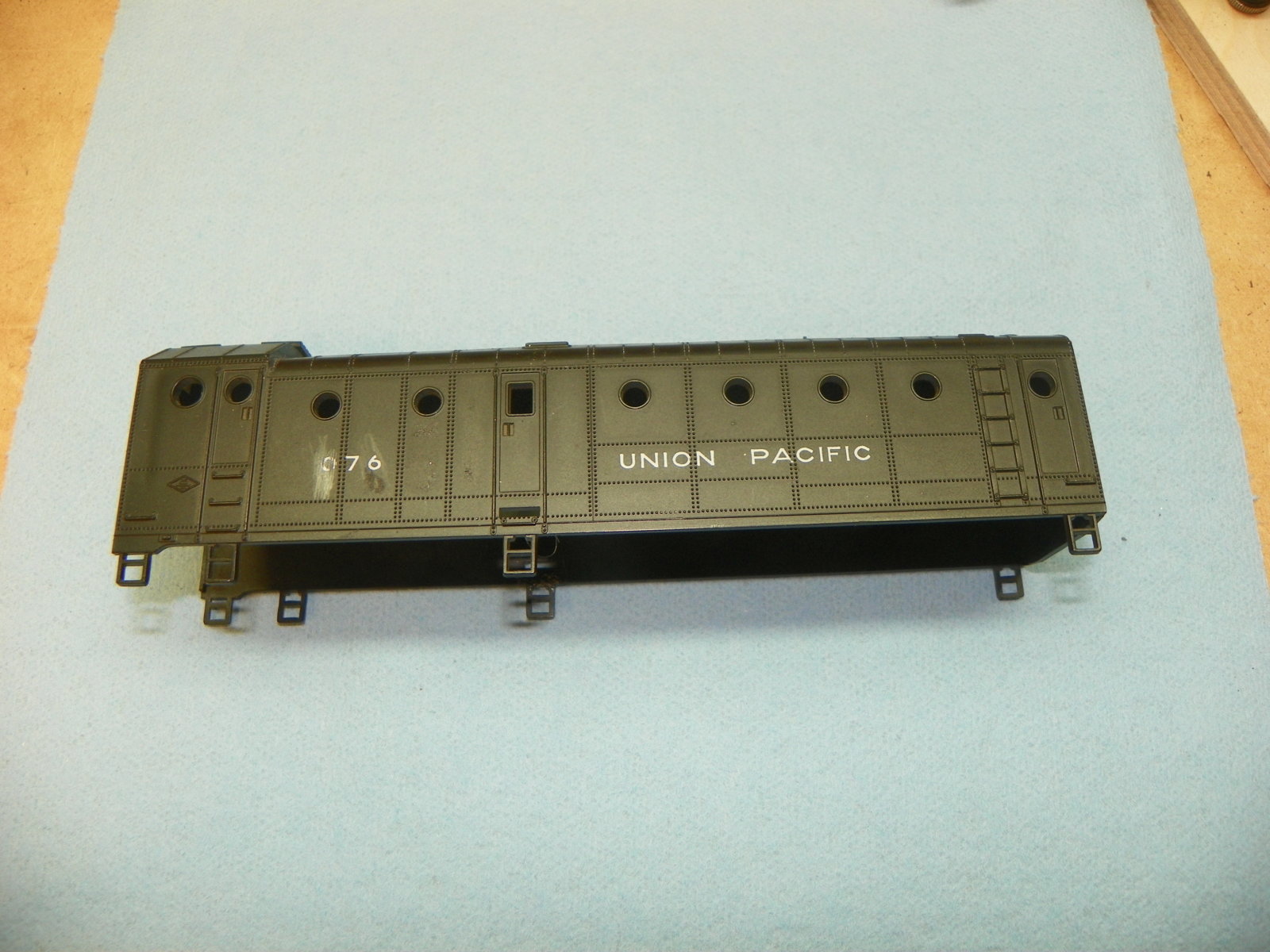

Before:

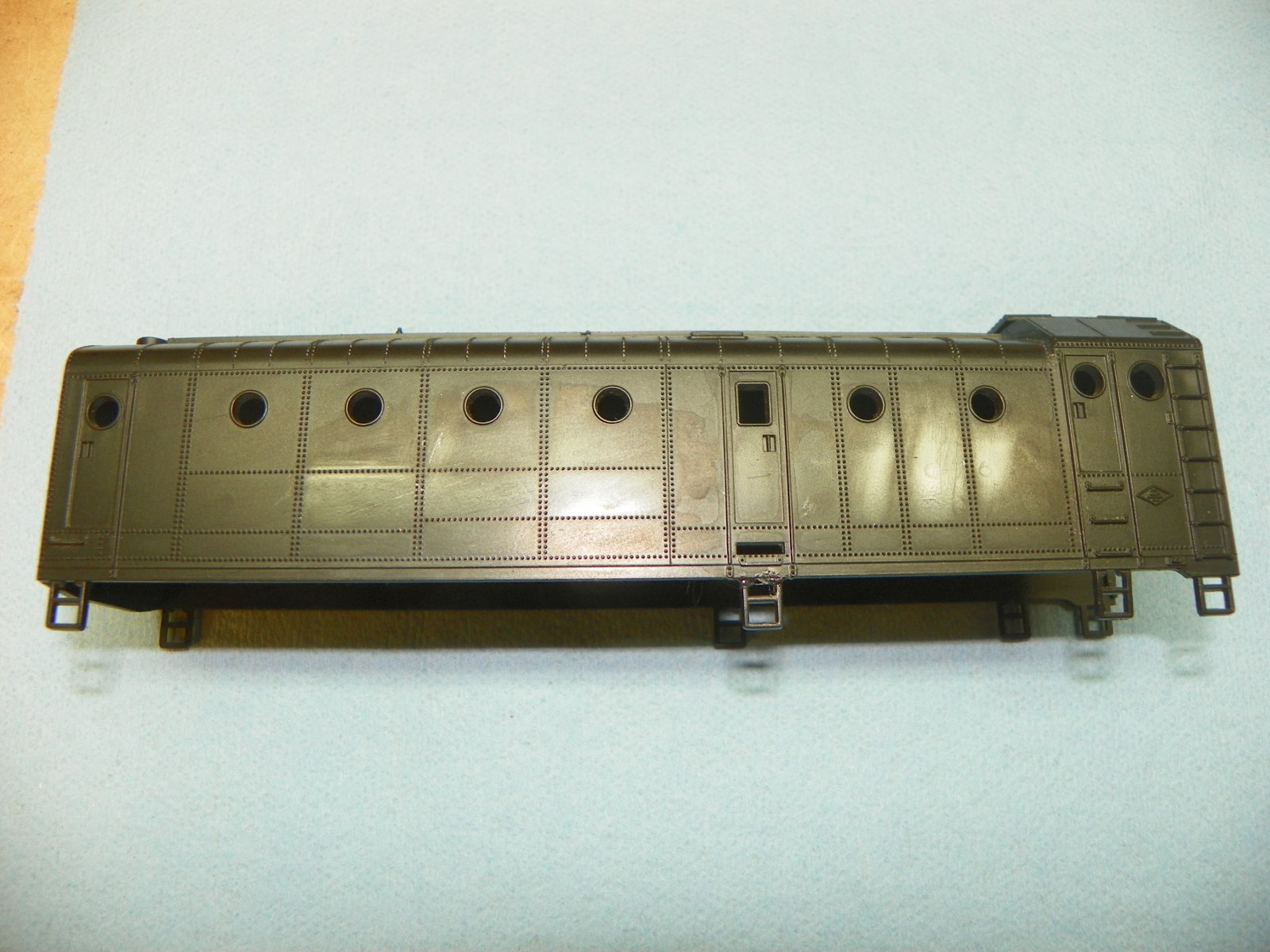

After:

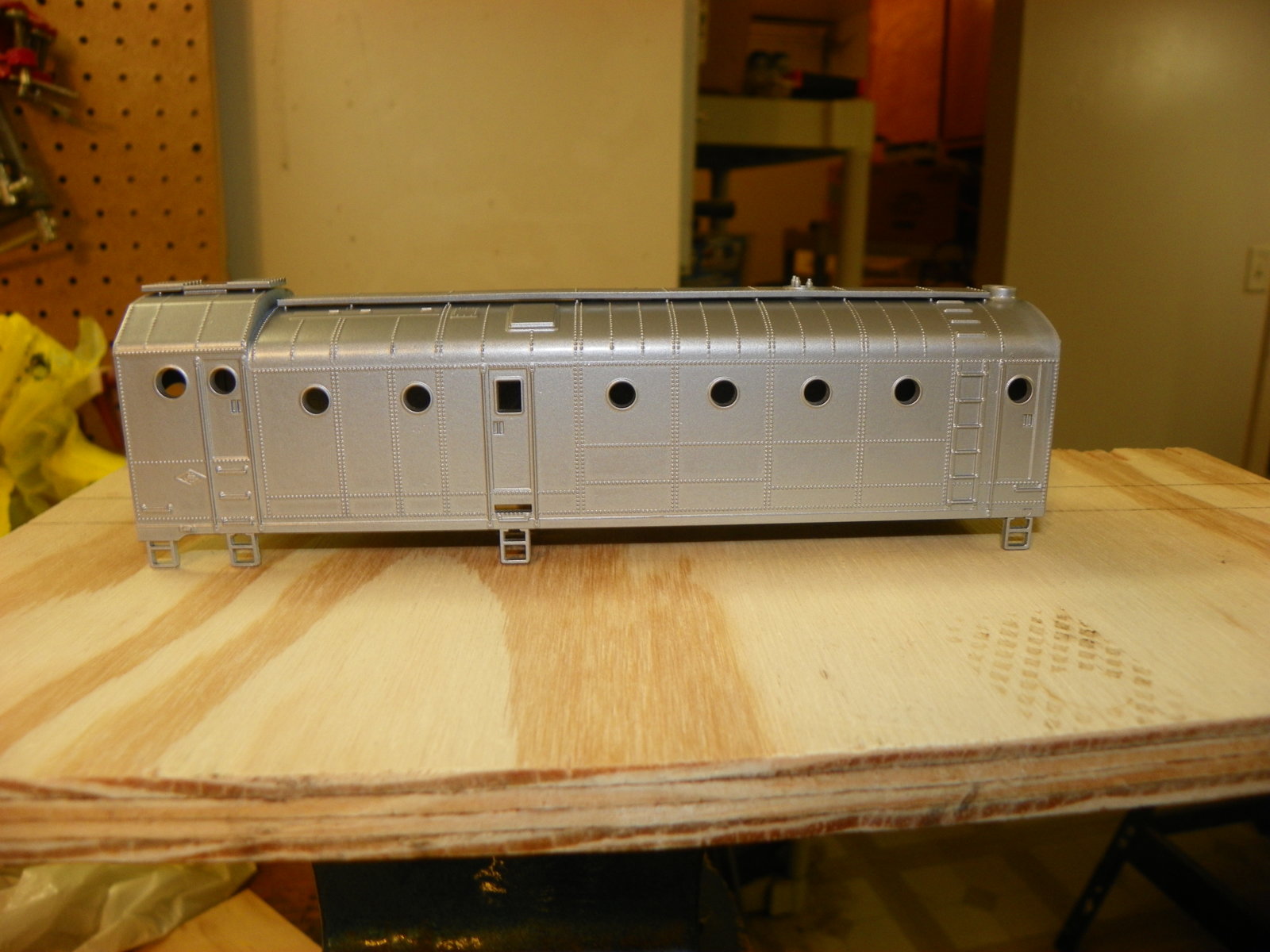

I used some Rustoleum plastic primer from a spray can and gave the model a coat of it. I washed the model thoroughly beforehand, though. Once that had dried, I used some Rustoleum Silver Metallic as the color coat. Here it is after one coat:

Its since had a second coat. It came out very nicely I think. Now to fix the chassis..........

Someone had "converted" this plow to run on battery power. There was a motor held to the chassis by a piece of wire, a battery box inside the car, and a switch mounted to the bottom of the chassis.

The plow is on top in this pic:

These items have since been removed. The front truck was held onto the pin by a piece of silicon tubing!

That is not the correct truck, anyway. A suitable replacement will be found for it. The prototype UP rotary plow #076 was built by Lima-Hamilton in January 1950. It was retired in June 1985. Here's a pic of it:

As you can see, the first order of business is a repaint. But first the decals have to come off. I tried removing them with a Bright Boy, but that wasn't such a bright idea. Then I found a YouTube video on removing decals. Use some toilet paper (on the model, that is) and cover the decal. Use a cotton swab and saturate the area with MicroSol, the decal solvent in a red bottle.

Wait 5 minutes for the solvent to work, the remove the tissue and use a dry cotton swab to clean the decal off the model.

Before:

After:

I used some Rustoleum plastic primer from a spray can and gave the model a coat of it. I washed the model thoroughly beforehand, though. Once that had dried, I used some Rustoleum Silver Metallic as the color coat. Here it is after one coat:

Its since had a second coat. It came out very nicely I think. Now to fix the chassis..........