Rabman

Active Member

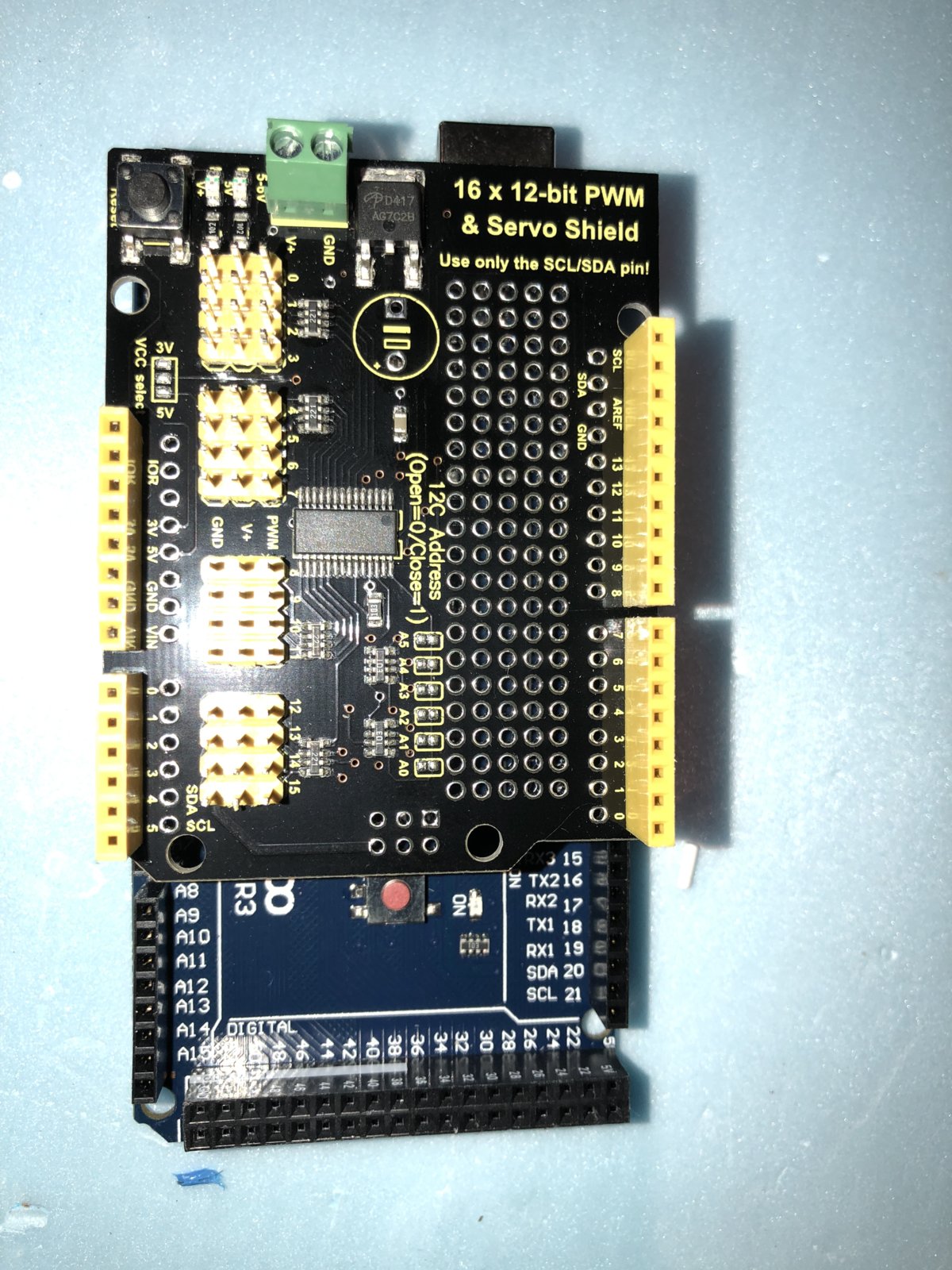

I have put together an Arduino Mega 2560 with a 16 channel x 12 bit Servo PWM shield to power my 12 Turnouts which include a double slip turnout and a 3-Way turnout.

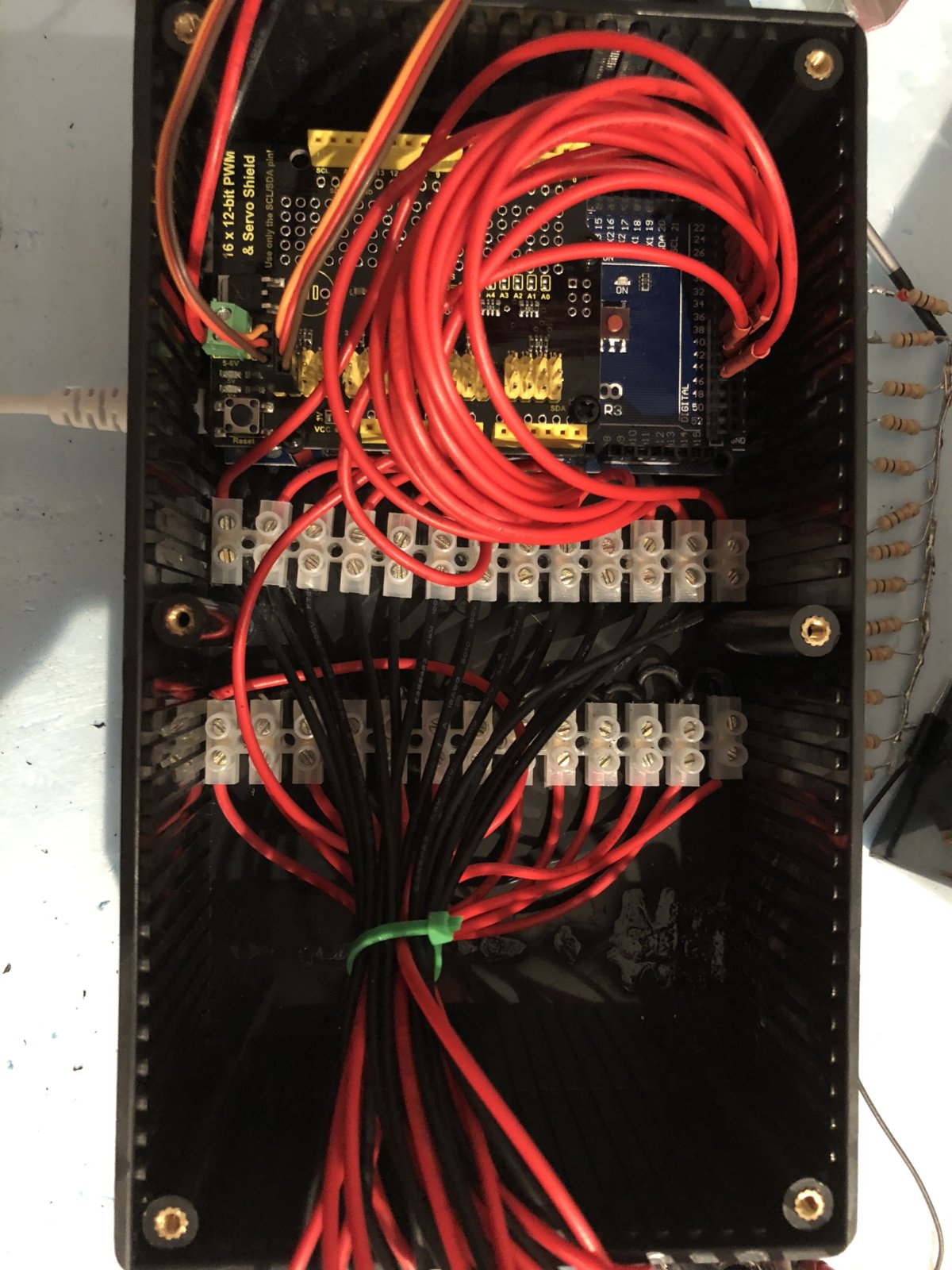

I am nearing the completion of the control box.

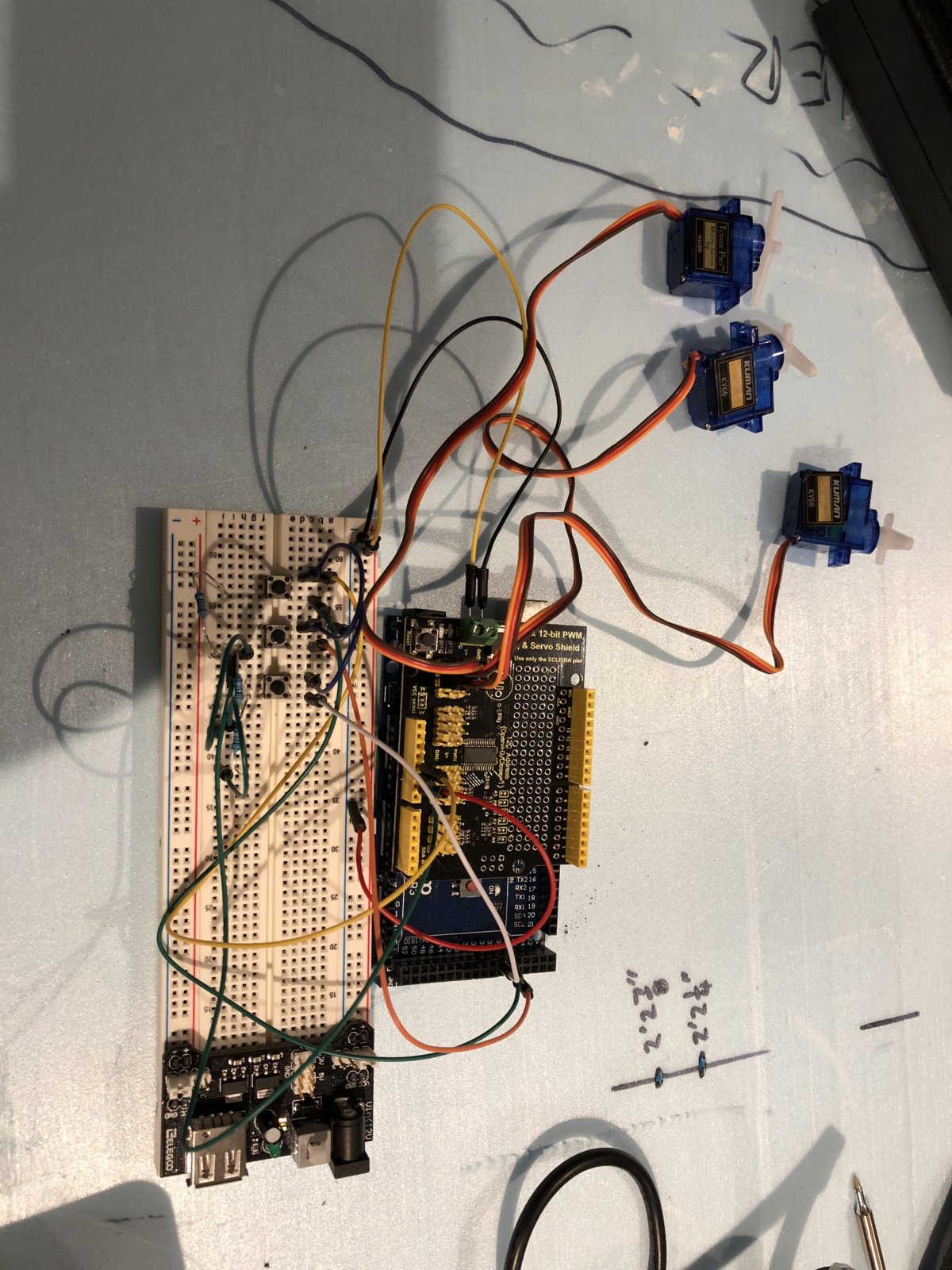

I am using one momentary push button switch per turnout and 3 switches for the 3-Way (1 per destination track) and two for the Double Slip.

In the end I am going to install one LED per switch, but not right now.

The program is written for the Arduino to operate the servos. It is a work in progress but I think it’s 95% complete.

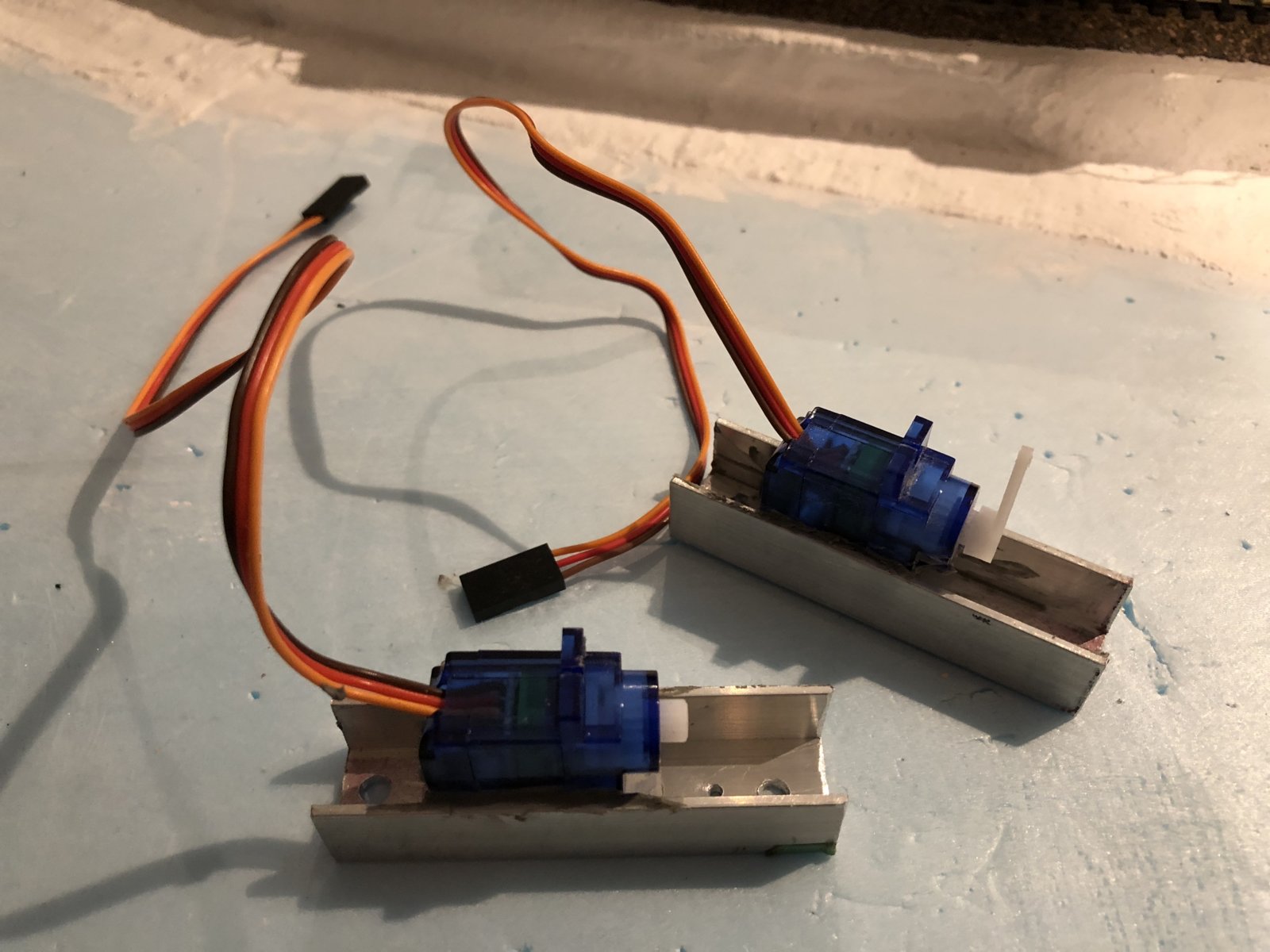

I purchased SG90 servos from Amazon with all the other electronic equipment. The bracket for the servos are made of 1/2” aluminum c-channel. The prototype assemblies mount the servos with Gorilla double sided tape. I am going to reinforce it with Gorilla single sided duct tape around the bracket and servo. I will see the longevity of this system but anticipate it will be good. The photo shows a previous attempt with latex chaulk as the adhesive but it wasn’t strong enough.

I have one installed and am playing with some software parameters to get the turnout throw just right.

Here are some photos.

I am nearing the completion of the control box.

I am using one momentary push button switch per turnout and 3 switches for the 3-Way (1 per destination track) and two for the Double Slip.

In the end I am going to install one LED per switch, but not right now.

The program is written for the Arduino to operate the servos. It is a work in progress but I think it’s 95% complete.

I purchased SG90 servos from Amazon with all the other electronic equipment. The bracket for the servos are made of 1/2” aluminum c-channel. The prototype assemblies mount the servos with Gorilla double sided tape. I am going to reinforce it with Gorilla single sided duct tape around the bracket and servo. I will see the longevity of this system but anticipate it will be good. The photo shows a previous attempt with latex chaulk as the adhesive but it wasn’t strong enough.

I have one installed and am playing with some software parameters to get the turnout throw just right.

Here are some photos.