I have successfully fixed cracked Life-Like gears by taking some K&S aluminum tubing of the proper diameter, cutting some very short pieces off (making collars), and pressing them on both hubs on of the cracked gear. Effectively squeezing the crack out of the hubs and gear.

Not for the weak of heart, though. I need to enlarge the aluminum collars by forcing them on an awl and stretching them slightly, and/or doing just a little filing on the hubs (chamfer the hub ends a tiny amount and even on the diameter a little bit) in order to get the collars pressed on to the hubs.

One could probably also use brass tubing, but the aluminum tubing is a tad softer and slightly easier to stretch (open up) with an awl. Once the collars are on, simply press the wheel axles back into the gears (ream out the gears if too tight, see further below), check and set the wheel gauge to the proper standard, then put the complete wheel assemblies back into the plastic truck frames.

After dropping the wheel assemblies in the plastic truck frames, check to make sure the collars clear the openings and don't rub on anything. In my experience, most of the time the collars cleared, but I ran into one truck one time that needed a slight shaving with an Exacto knife to create some clearance so the collars wouldn't rub on the truck frame.

In most of my cases, after reassembly, the loco will run just as quiet as before. In a few cases, I have noticed an almost imperceptible "click" as the loco runs, but nowhere near the very audible clicking and/or chattering noises and slipping like you get with a normal broken gear. In all cases, the locos ran nice and smooth, imperceptible click or not.

And, if you don't want to go through all this horse-pucky, I don't blame you. It's still far easier just to get some new Athearn gears for a quick, easy replacement. I had to invent the collar fix because I couldn't find any new gears in stock anywhere when I needed some. During the Covid shortages, go figure. I finally got a hold of some Athearn gears and have been able to use them instead. One thing I have done however, is to ream out the gear bores

by hand slightly bigger, so they're not such a blasted tight fit on the axle shafts. This could possibly contribute to future cracking of the new gears. I use a #42 drill bit for reaming, it opens up the bore slightly yet still yields a nice, tight fit. A regular 7/64" diameter drill bit will also work as a reamer for those that do not have access to numbered drill bits. This will yield a slightly LESS tight fit than the #42 bit, but still tight enough to do the job, in my opinion.

This fix is for HO-scale Life-Like locos with cracked gears. I don't know if it will work for Bachmann or other brands or not, I haven't had any experience with cracked gears on any of them. Owners of those brands will have to judge for themselves if the hub collar idea is feasible for them or not.

Hope this helps. And if you care to try it, hopefully you will have some success, too. Like I say it worked good for me.

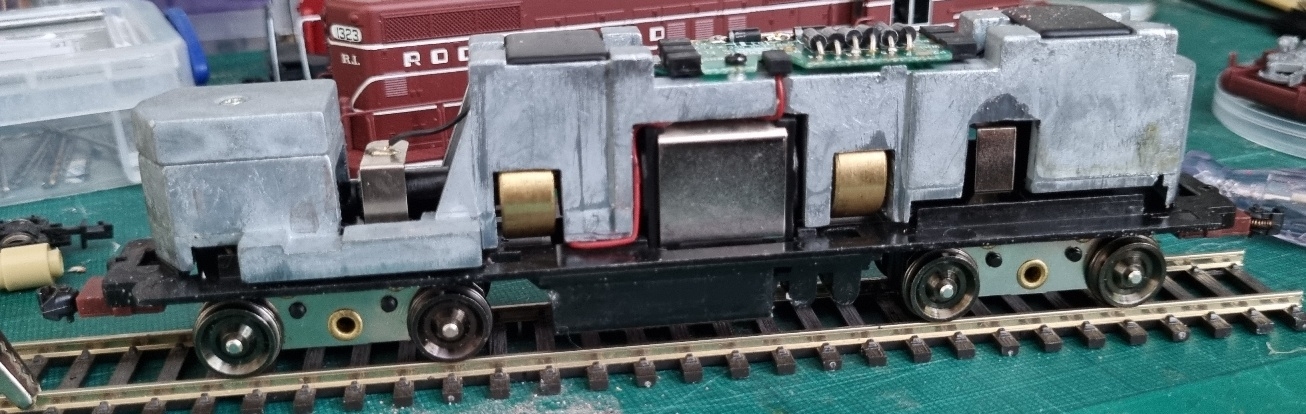

Here's a set of 4 cracked gears (strung on a twisty-tie for safe keeping) that have been fixed with aluminum collars, all ready to go on the next Life-Like HO-scale 4-axle diesel needing some replacement gears. A friend's Highway Miniatures Erie B-2 Steam Crane that I built for him is graciously holding them up for the photo.